A water treatment device containing round tube packing and its use method

The technology of a water treatment device and a circular tube is applied in the field of water treatment, which can solve the problems of poor denitrification and dephosphorization, difficult maintenance, and reduced total surface area, so as to achieve a state that is beneficial to anaerobic denitrification and dephosphorization, and protects organisms. , the effect of design size increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

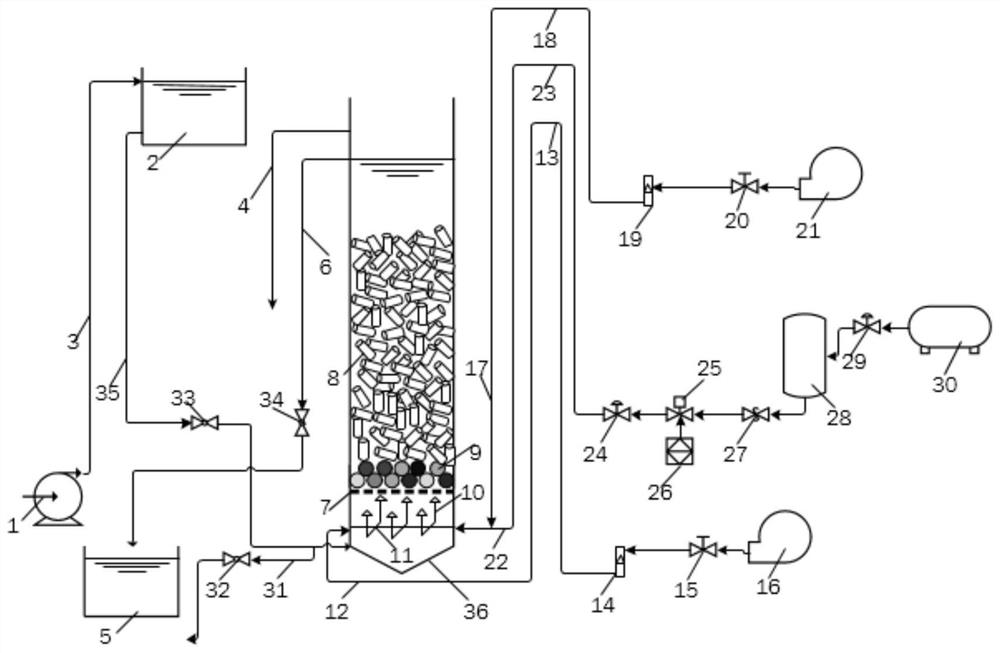

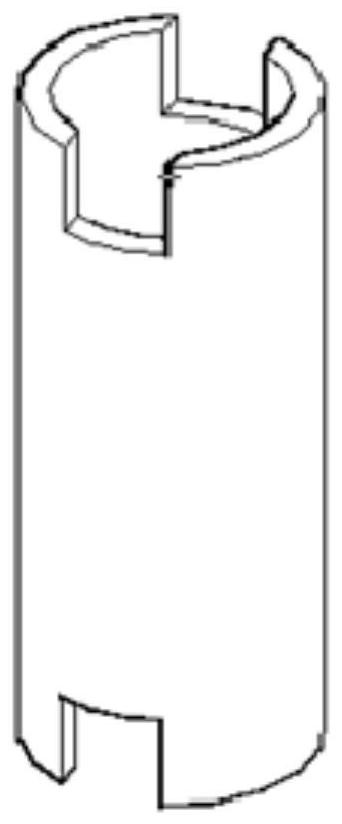

[0026] Embodiment 1: Select a smooth pipe section with an outer diameter of 5 mm, a pipe length of 16 mm, a wall thickness of 1 mm, and an inner diameter of 3 mm. The specification of the round tube packing is Φ2.1×L16mm, and the specific surface area is 1066m 2 / m 3 and a density of 1.19g / cm 3 . There are rectangular U-shaped grooves with a length of 1.5mm and a height of 2mm at both ends.

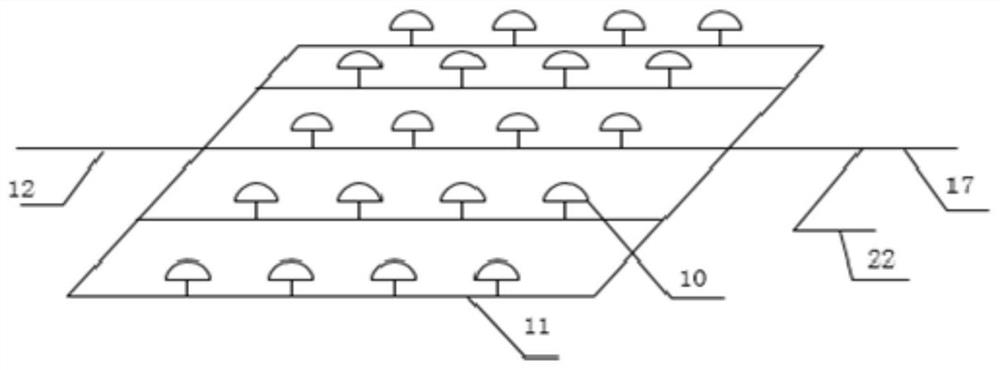

[0027] The thickness of the gravel layer on the support plate of the application device is 10cm, the packing height is 500mm, the liquid level in the device is 1050mm, and the volume is 18.55L.

[0028] The sewage with COD concentration of 50-300mg / L and ammonia nitrogen concentration of 20-60mg / L is taken for biochemical treatment. During the operation, the dissolved oxygen content should be kept at 3-5mg / L, and the water temperature should be controlled at 22±4°C. The system operates 2 cycles a day, and each cycle operates according to the process of "water intake 20min→aeration 9h...

Embodiment 2

[0030] Example 2: According to the C / N ratio and N content of the influent, the packing is kept running in a static state or a fluidized state.

[0031] The round tube packing is filled in the reactor to analyze the influent water quality. When the C / N is less than 100:5 and the proportion of nitrogen and phosphorus is high, the sewage is low in organic matter and high in nitrogen and phosphorus. Adjust the treatment process to favor anaerobic denitrification. The operation and treatment effect is better in the static state. Open the aeration valve 15, close the air supply valve 20, intermittently open and close the pulse solenoid valve 25 and the time controller 26, adjust the first flow meter 14, control the air-water ratio at 1:2, dissolve The oxygen content is 2-5mg / L, so that the air buoyancy F1+water buoyancy F2<the gravity G of the packing with film, so that the round tube packing is in a state of static sinking.

[0032] When the C / N is greater than 100:5, the proporti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com