Eccentric fine adjusting structure of hardboard shearing machine

A shearing machine and cardboard technology, applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of irregular trimming, missed cutting of cardboard, inconvenient adjustment of pressing rollers, etc., to meet the requirements of adjusting rollers needs, easy adjustment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments. It should be understood that the examples are only for explaining the present invention and not for limiting it.

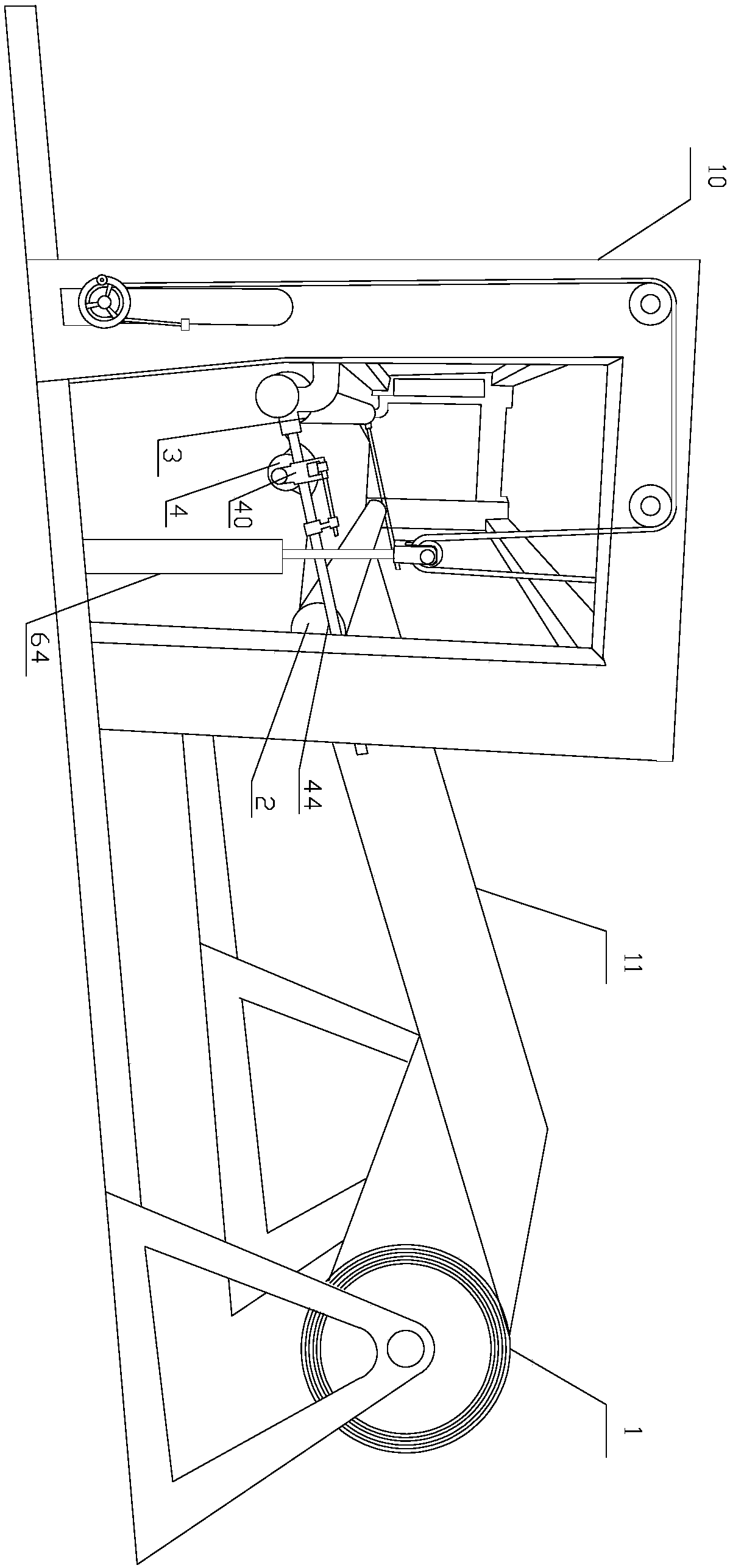

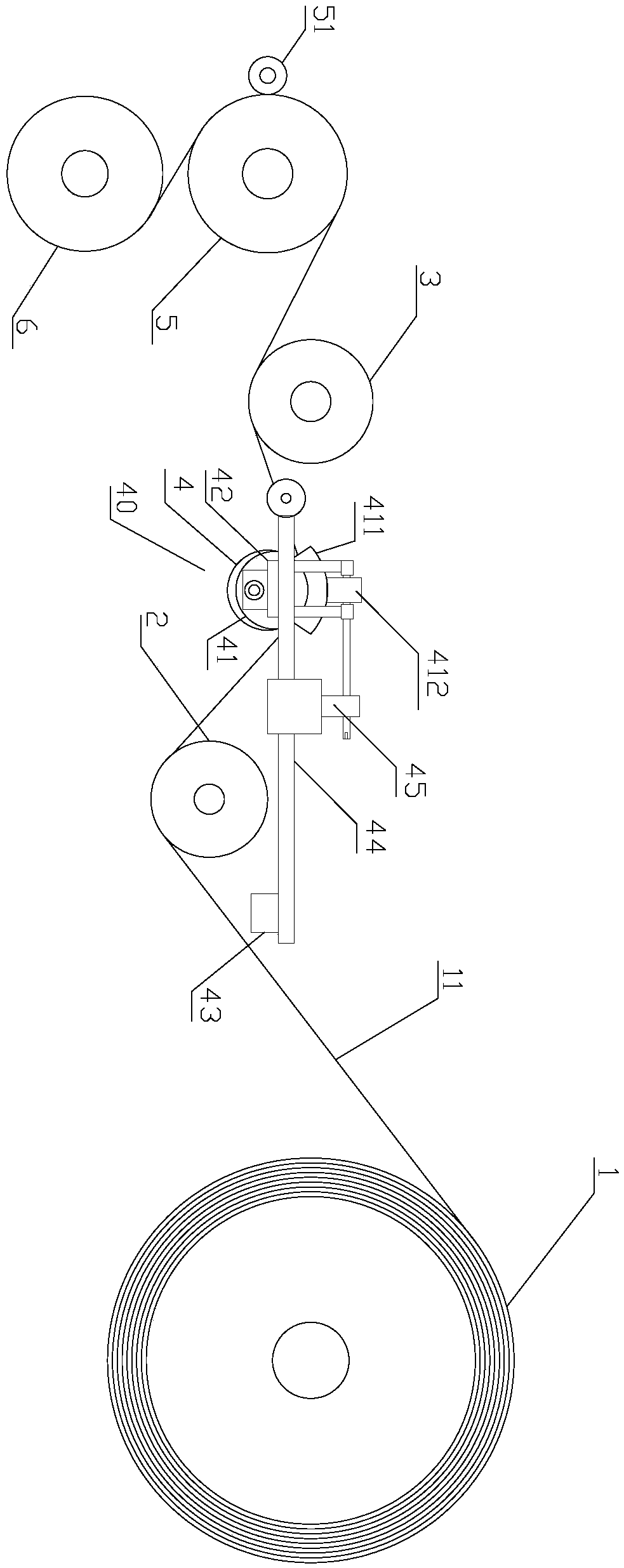

[0014] As shown in the figure, an eccentric fine-tuning structure of a cardboard shearing machine includes a door-shaped or other-shaped frame body 10, and the frame body 10 is sequentially provided with a raw material roll 1, a first pressure roll 2, and a pressure adjustment roll. Roller 4, second pressing roller 3, cutting roller 5, receiving roller 6 and edge material recycling mechanism. The raw material roll 1 is an original larger hard roll produced by a paper mill. Both ends of the adjusting pressure roller 4 are provided with an eccentric fine-tuning structure 40, and a cutting knife 51 is provided on the crossbar 12 of the frame body 10 on one side of the cutting roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com