Steel structure displayer support

A display stand and steel structure technology, applied in the direction of machine/stand, instrument, support machine, etc., can solve the problems of not being light enough, bulky, heavy arms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

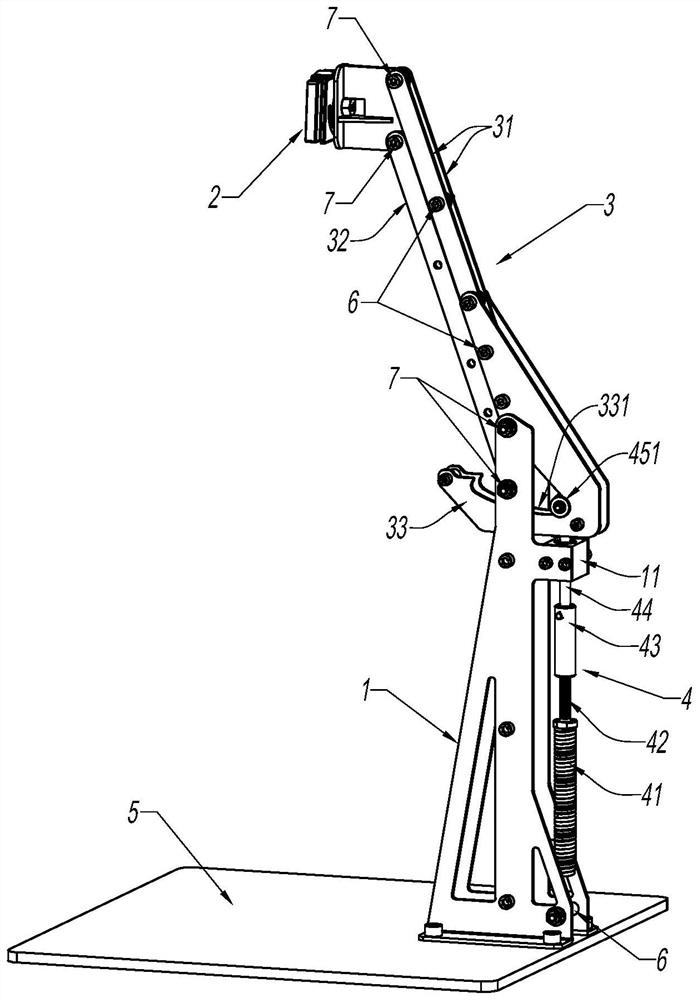

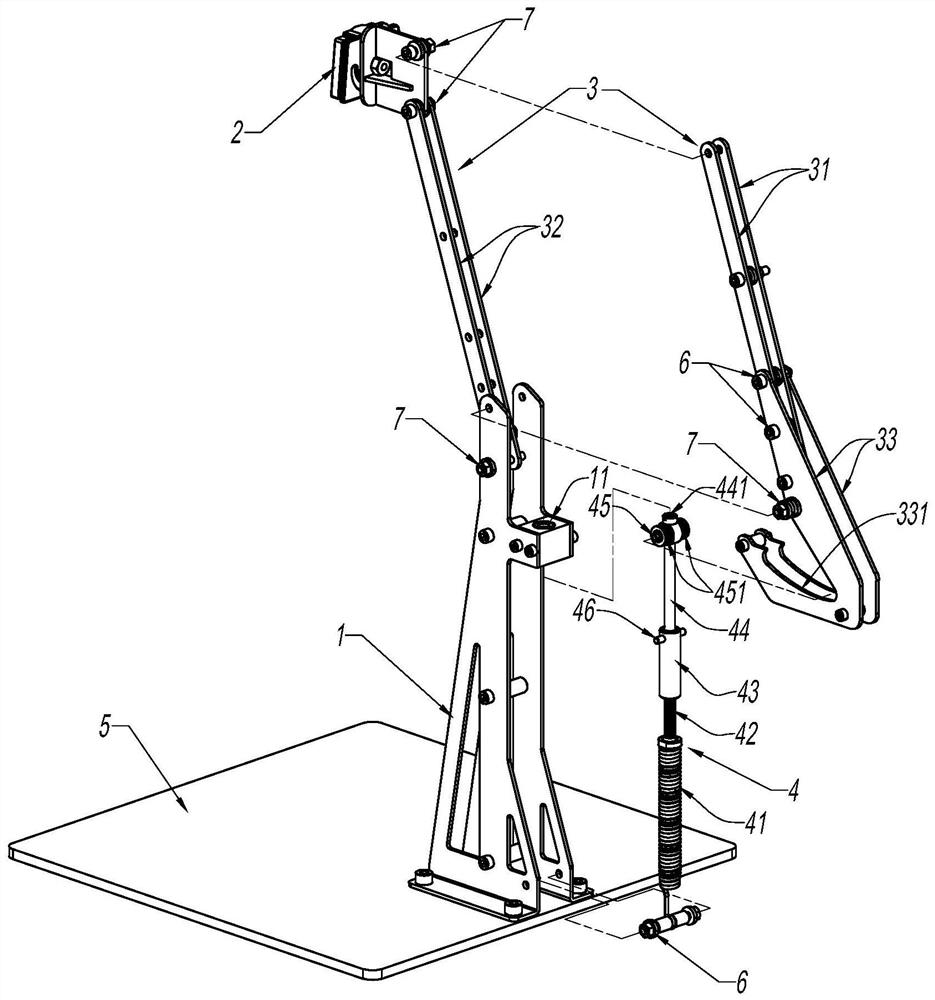

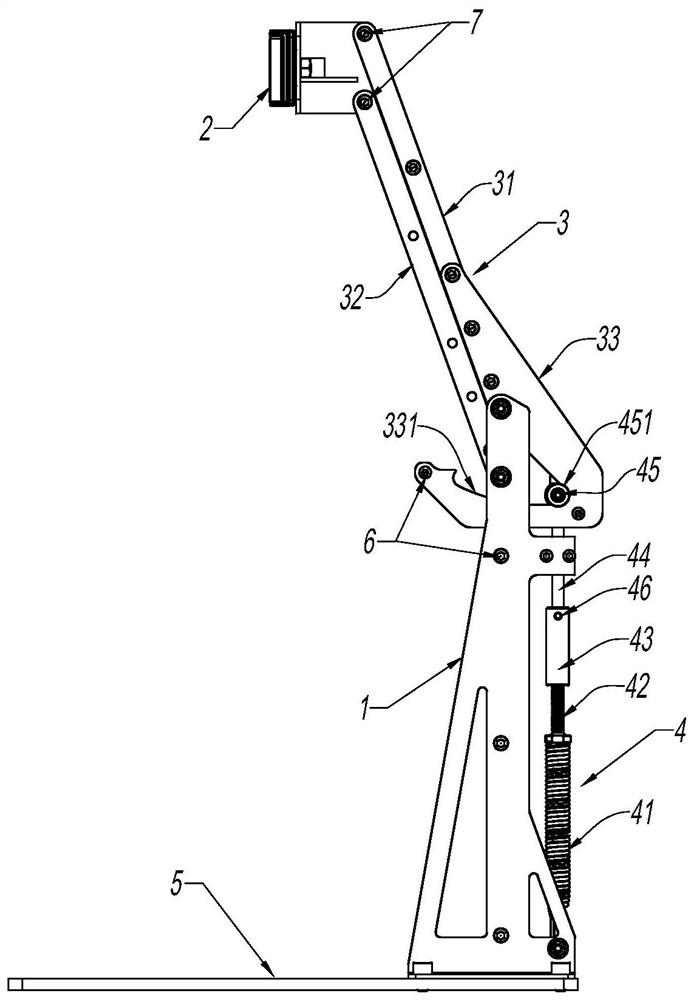

[0024] refer to Figure 1 to Figure 4 , The steel structure display stand includes a support base 1, a suspension base 2, a cantilever assembly 3 and a spring assembly 4, and a base 5 for fixing the support base.

[0025] The cantilever assembly 3 includes an upper cantilever 31 , a lower cantilever 32 and an arc-shaped hook 33 ; The two ends of the upper cantilever 31 and the lower cantilever 32 are respectively hinged on the support base 1 and the suspension base 2 to form a four-bar linkage mechanism. The four-bar linkage mechanism is provided with a preload by the spring assembly 3 and can be kept in a load-bearing state. The upper cantilever 31 and the lower cantilever 32 are in a parallel state and have a more compact shape, forming a parallel four-bar linkage mechanism.

[0026] The spring assembly 4 includes an elastic body 41, an adjusting screw 42, a nut column 43 and a sliding shaft 44; one end of the elastic body 41 is hung on the lower part of the support base 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com