Butt joint method for giant rotary kiln barrels

A rotary kiln, extra-large technology, applied in the direction of rotary drum furnace, furnace type, furnace, etc., can solve the problems of increasing construction difficulty, and achieve the effect of simple method of checking concentricity, simple method and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

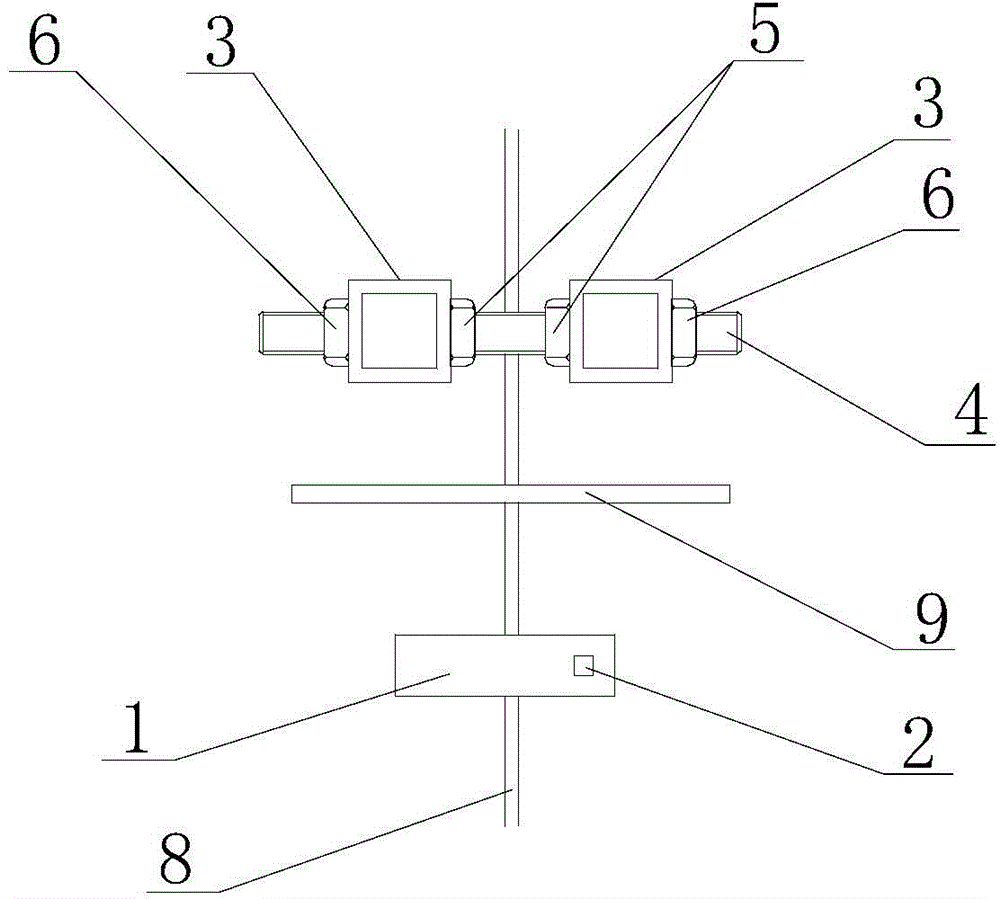

[0026] like Figure 1 to Figure 6 As shown, the extra-large rotary kiln barrel docking method of the present invention comprises the following steps:

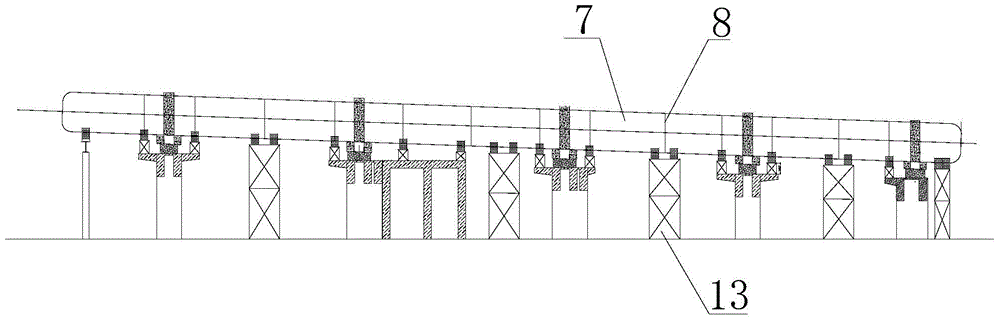

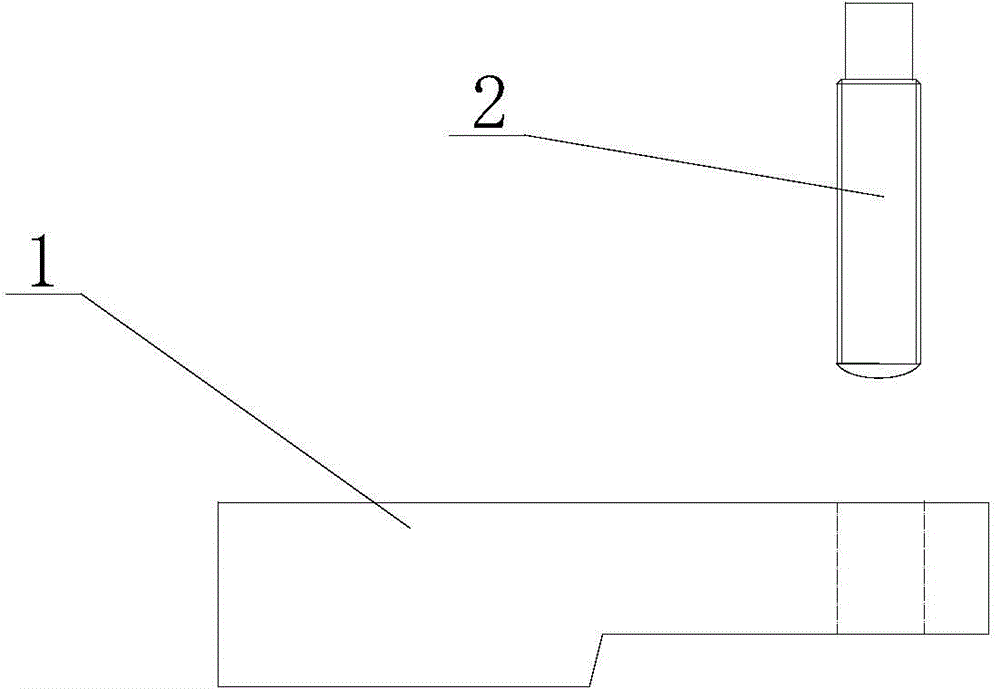

[0027] a. Set up a temporary support 13 that can be adjusted to lift. The temporary support 13 is erected along the installation and arrangement direction of the cylinder body 7 and is compatible with the weight, shape and installation height of the cylinder body 7; The erection density increases accordingly. The lighter the cylinder body 7 is, the thinner the erection density of the temporary support 13 is, and the cost is saved as much as possible under the condition of satisfying safe construction; similarly, the shape of the temporary support 13 is erected according to the shape of the cylinder body 7. The height of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com