Winding wire insulating layer ring cutting device and ring cutting system applying same

A winding wire and insulation layer technology, applied in the field of winding wire quality inspection, can solve problems such as low efficiency, hidden dangers, and inability to form a closed loop, and achieve the effects of convenient and intuitive adjustment of load force, improvement of work efficiency, and reliable and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

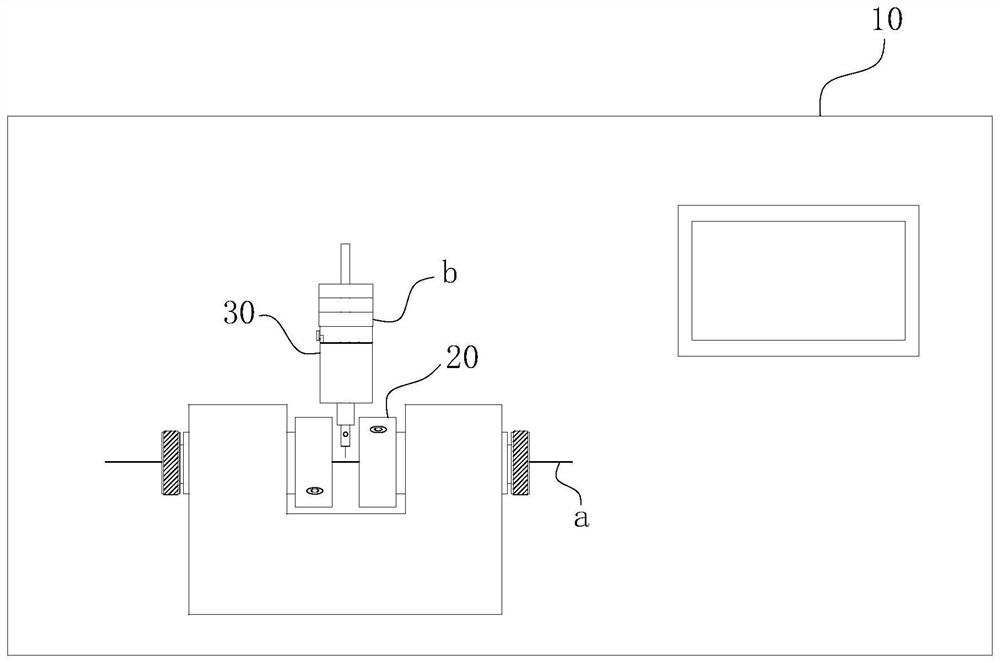

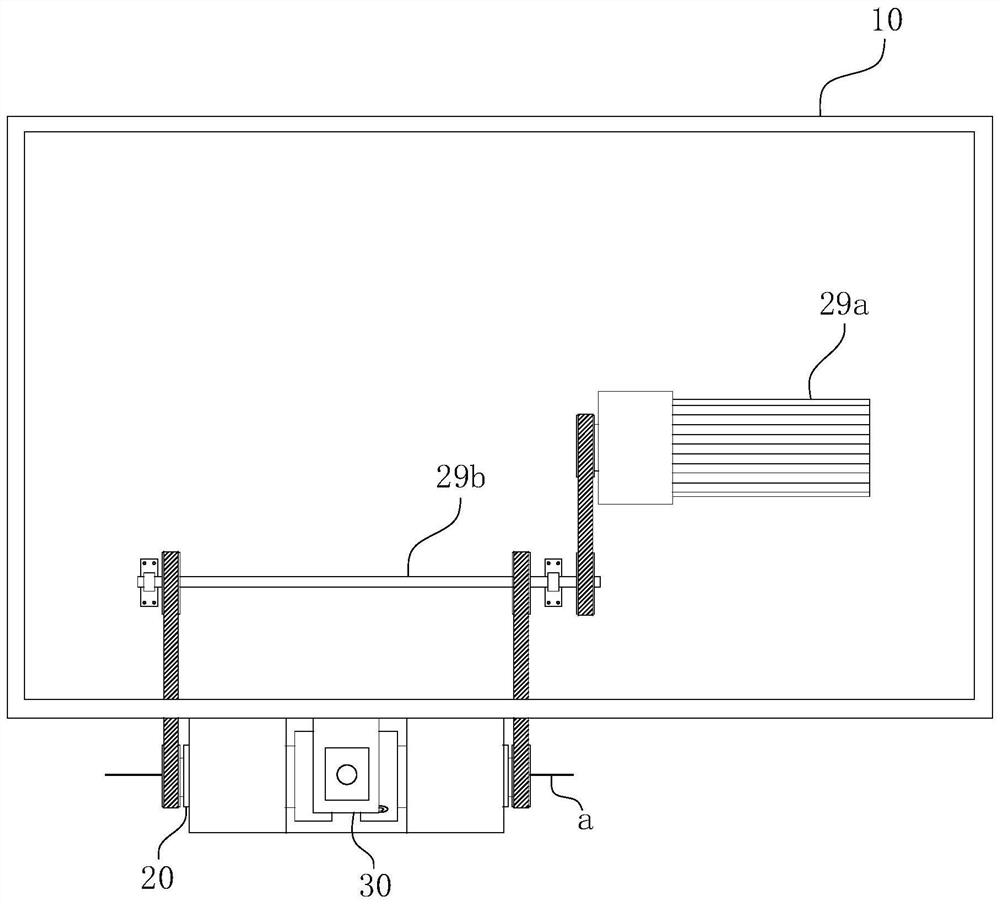

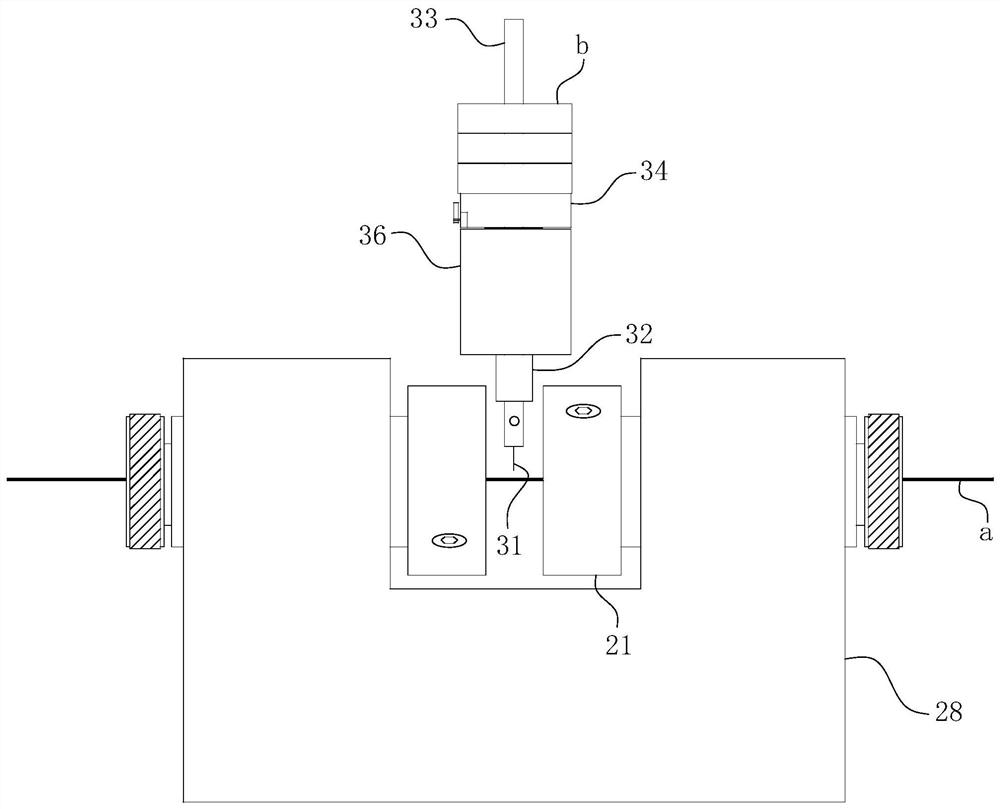

[0045] For ease of understanding, combined here Figure 1-9 , the concrete structure and working mode of the present invention are further described as follows:

[0046] The specific structure of the present invention is as Figure 1-9 As shown, its main structure includes a frame 10 and a locking assembly 20 and a ring cutting assembly 30 located on the frame 10; the installation positions of the locking assembly 20 and the ring cutting assembly 30 refer to figure 1 and image 3 shown. in:

[0047] The locking assembly 20 includes a "U"-shaped trough-shaped workbench 28 fixed on the frame 10 , and two groups of claws are coaxially and oppositely arranged on the two sides of the workbench 28 . when working, such as Figure 1-2 As shown, the winding wire a is straightened and passed through two sets of claws, and then clamped and fixed by two sets of claws. The power starts from the power motor 29a with the driving wheel, passes through the transition rod 29b with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com