Gauze folding and unloading mechanism for medical gauze folding machine

A folding machine and gauze technology, applied in the direction of thin material processing, sending objects, packaging, etc., can solve the problems of affecting the integrity, different folding sizes, different packaging folding, etc., to ensure the quality, the size is equal, and the effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

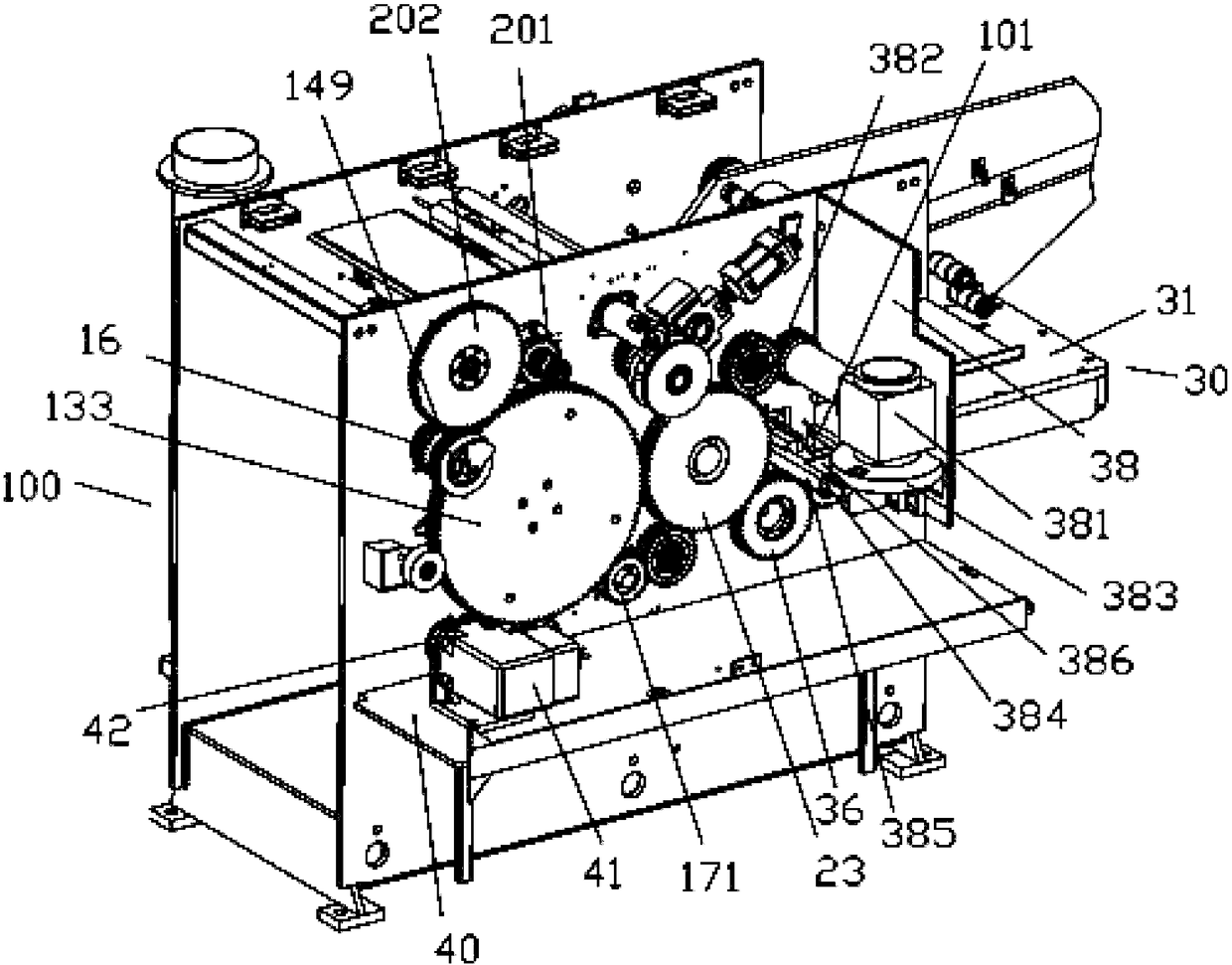

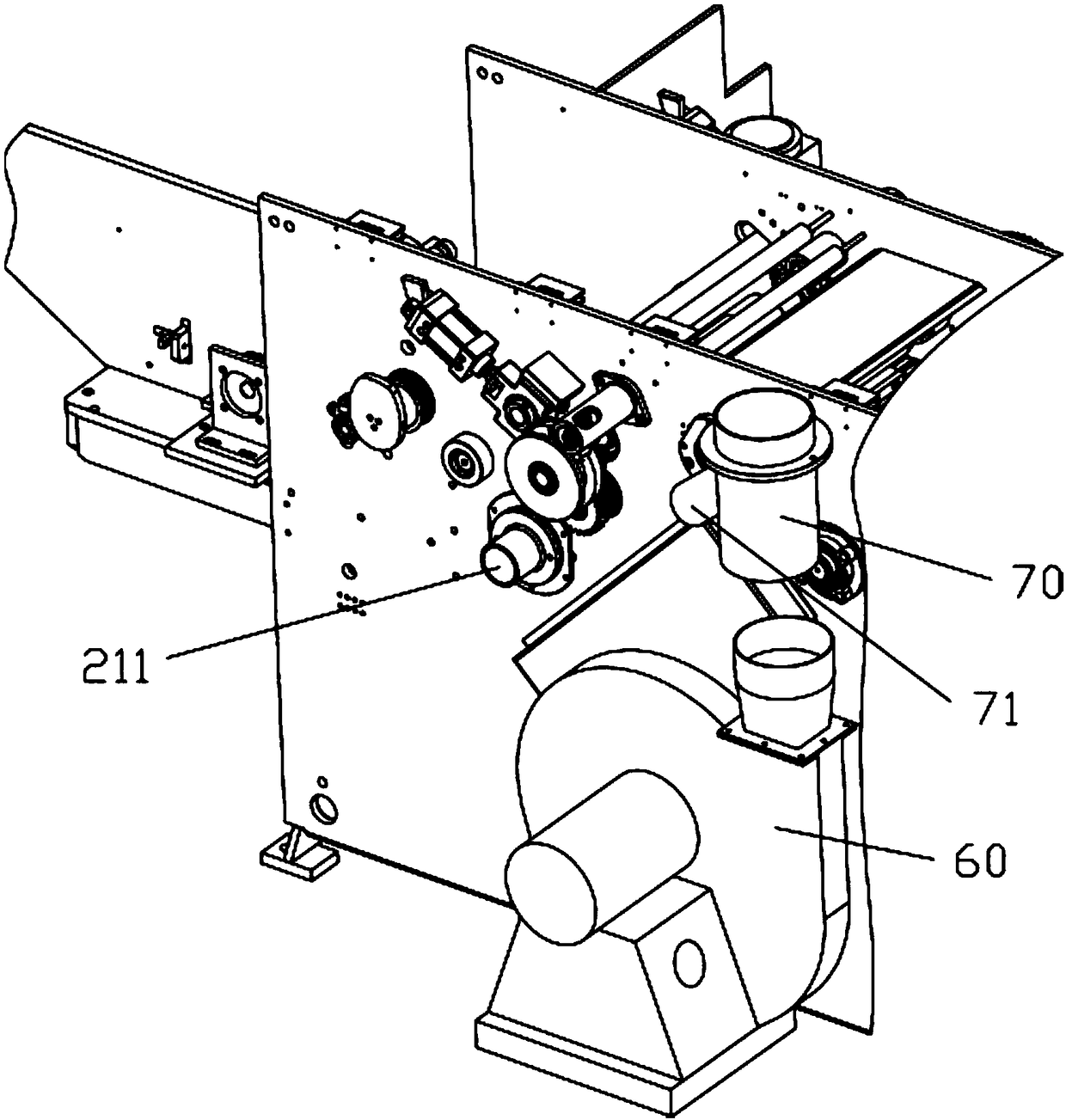

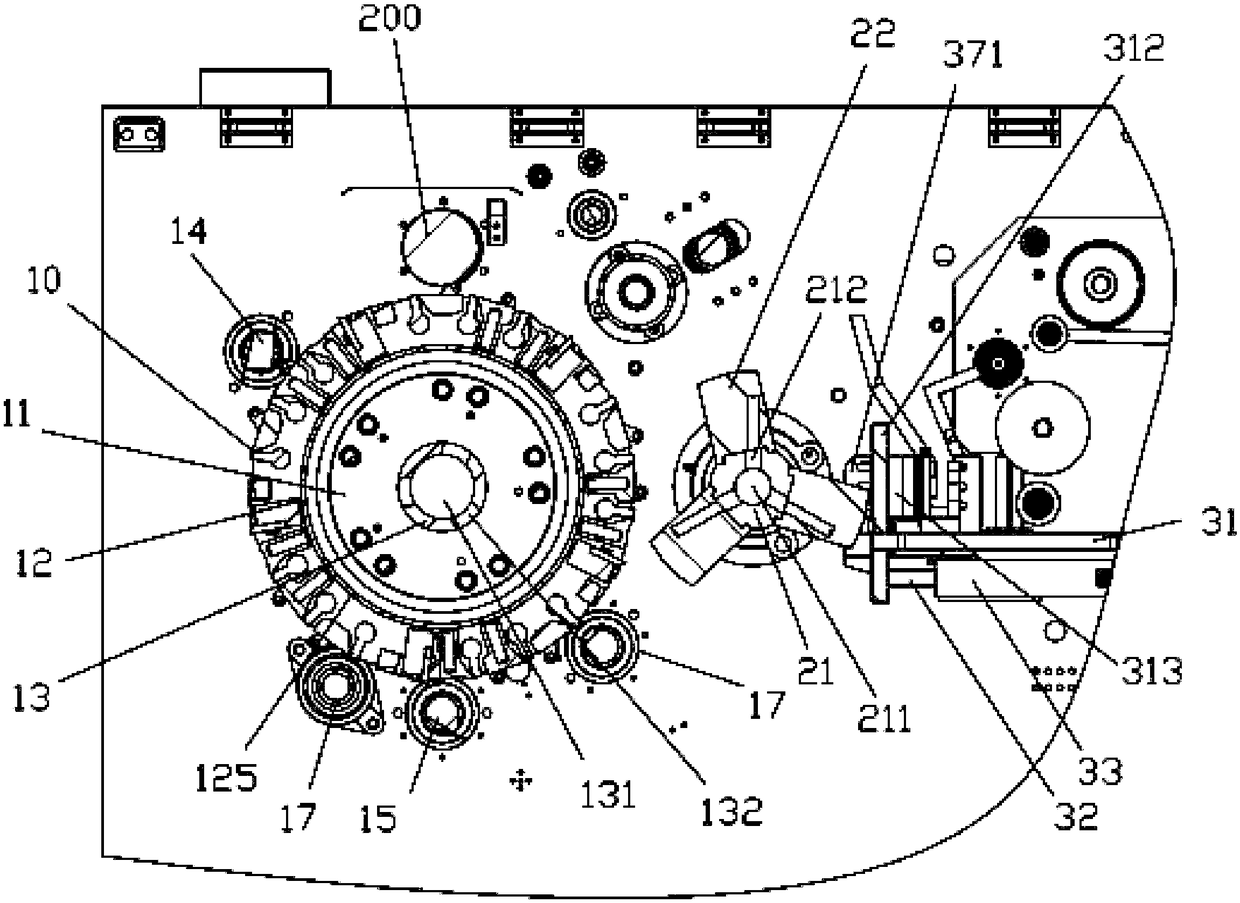

[0041] Examples, see e.g. Figure 1 to Figure 13 As shown, a gauze folding and unloading mechanism for a medical gauze folding machine includes a main body housing 100, the main body housing 100 is provided with an adsorption cutting wheel 10, and the adsorption cutting wheel 10 includes two end plates 11 and an outer sleeve 12. The two ends of the outer sleeve 12 are fixed on the two end plates 11, the middle of the two end plates 11 is fixed with the main shaft 13, and the two ends of the main shaft 13 are hinged on the front and rear side plates of the main body casing 100 through bearings The middle part of the rear end of the main shaft 13 has a central hole 131 extending to the front end, the central hole 131 communicates with the side through hole 132 formed on the side wall of the main shaft 13, and the outer sleeve 12 is fixed with a plurality of outer wall surfaces. The outer adsorption connecting plate 121 with the adsorption through hole 1211, the side adsorption c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com