Polyester fiber polyester slicing dust removal device

A technology of polyester slices and polyester fibers, which is applied in the direction of solid separation, filter screen, grid, etc., which can solve the problems of low efficiency of slicing devices, low quality of finished products, impossibility of impurity removal and filtration, etc., and achieve good shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

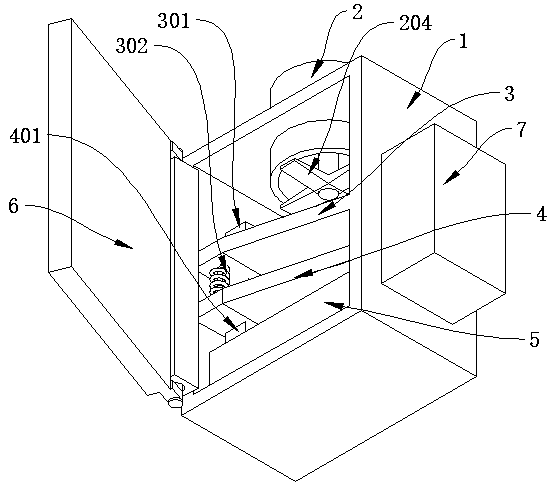

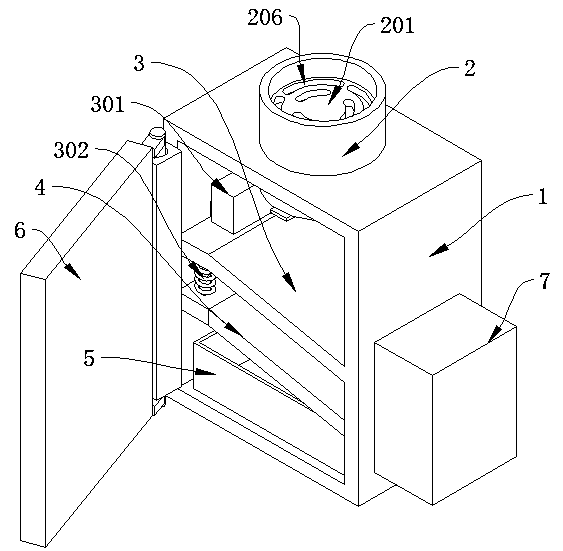

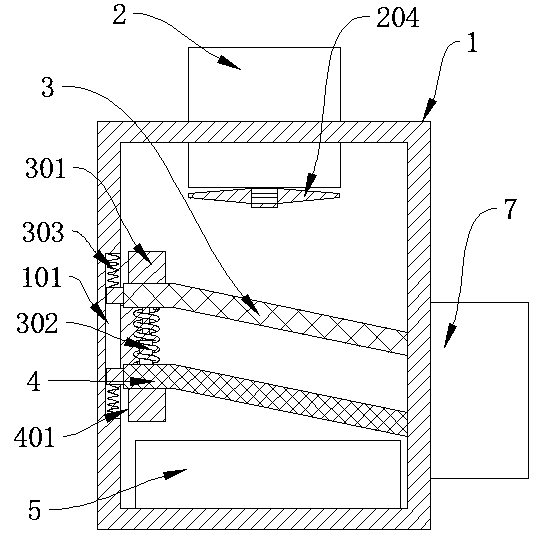

[0030] refer to Figure 1-3 , a polyester chip dust removal device for polyester fiber, comprising a box body 1, the top of the box body 1 is connected with a collection cylinder 2, the bottom of the collection cylinder 2 is rotatably connected with a cutter 204, and the inner wall of the box body 1 passes through the chute 101 longitudinally in sequence The first dust removal net 3 and the second dust removal net 4 are slidingly connected, the side wall of the box body 1 is connected with the waste box 7 corresponding to the first dust removal net 3 and the second dust removal net 4, and the inner wall of the bottom of the box body 1 is connected to the collection box 5, The side wall of the box body 1 is rotatably connected with the box door 6. When the user uses it, the polyester fiber is put in from the collection barrel 2, and then sliced by the cutter 204 at the bottom of the collection barrel 2, and then the cut material passes through the first A dust removal net 3 a...

Embodiment 2

[0032] refer to Figure 1-5 , a polyester chip dust removal device for polyester fiber, comprising a box body 1, the top of the box body 1 is connected with a collection cylinder 2, the bottom of the collection cylinder 2 is rotatably connected with a cutter 204, and the inner wall of the box body 1 passes through the chute 101 longitudinally in sequence The first dust removal net 3 and the second dust removal net 4 are slidingly connected, the side wall of the box body 1 is connected with the waste box 7 corresponding to the first dust removal net 3 and the second dust removal net 4, and the inner wall of the bottom of the box body 1 is connected to the collection box 5, The side wall of the box body 1 is rotatably connected with the box door 6. When the user uses it, the polyester fiber is put in from the collection barrel 2, and then sliced by the cutter 204 at the bottom of the collection barrel 2, and then the cut material passes through the first A dust removal net 3 a...

Embodiment 3

[0035] refer to Figure 1-5 , a polyester chip dust removal device for polyester fibers, which is basically the same as that of Embodiment 2, furthermore, a first spring 210 is sleeved on the slide bar 209, and the two ends of the first spring 210 are connected with the baffle plate 207 and the feeding material respectively. The inner wall of the plate 201 is pressed against each other, and the baffle plate 207 is automatically reset by the first spring 210 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com