Brush belt

a belt and brush technology, applied in the field of brush belts, can solve the problems of complicated belt body production and relatively rapid contamination of brush belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

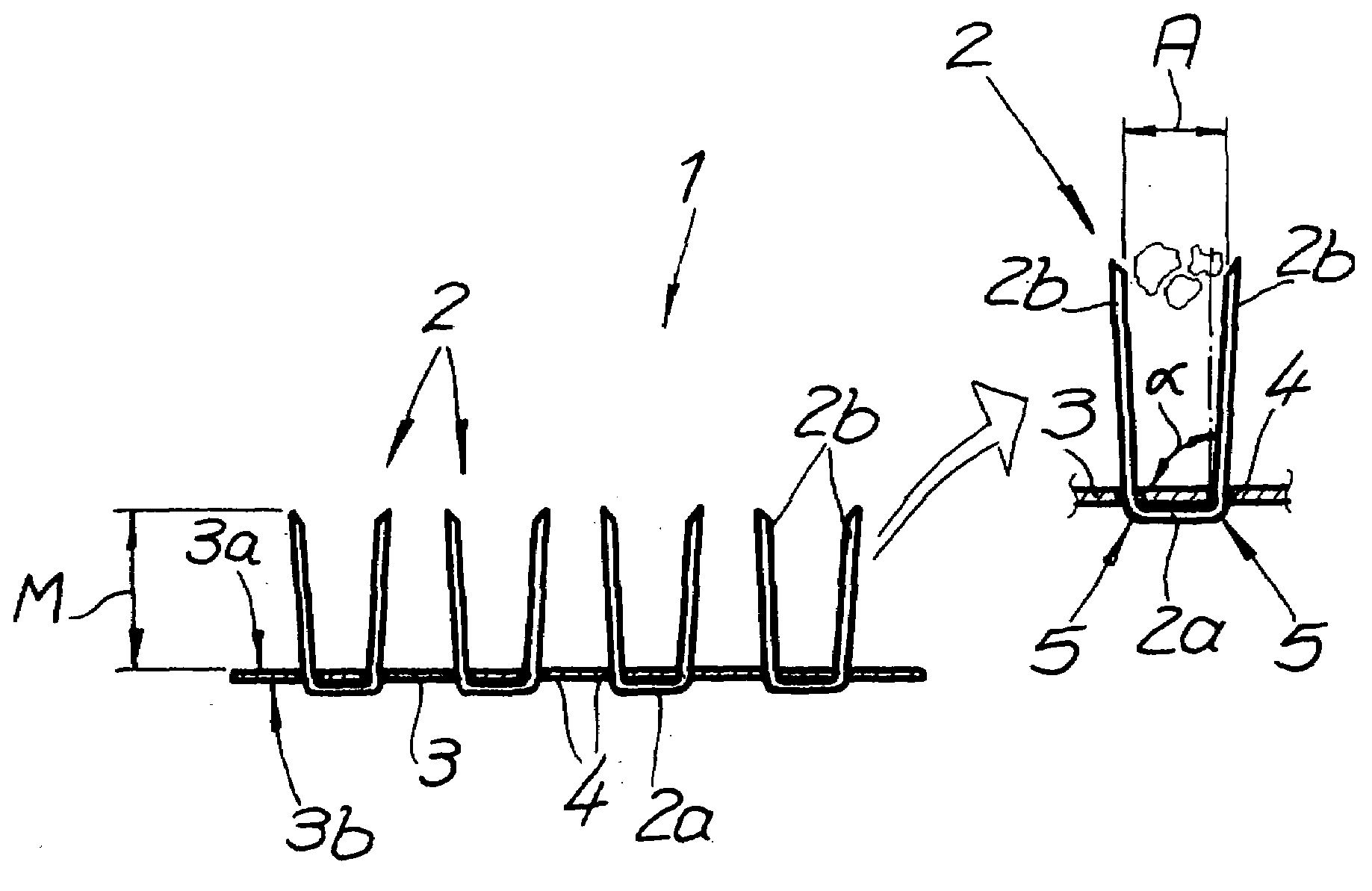

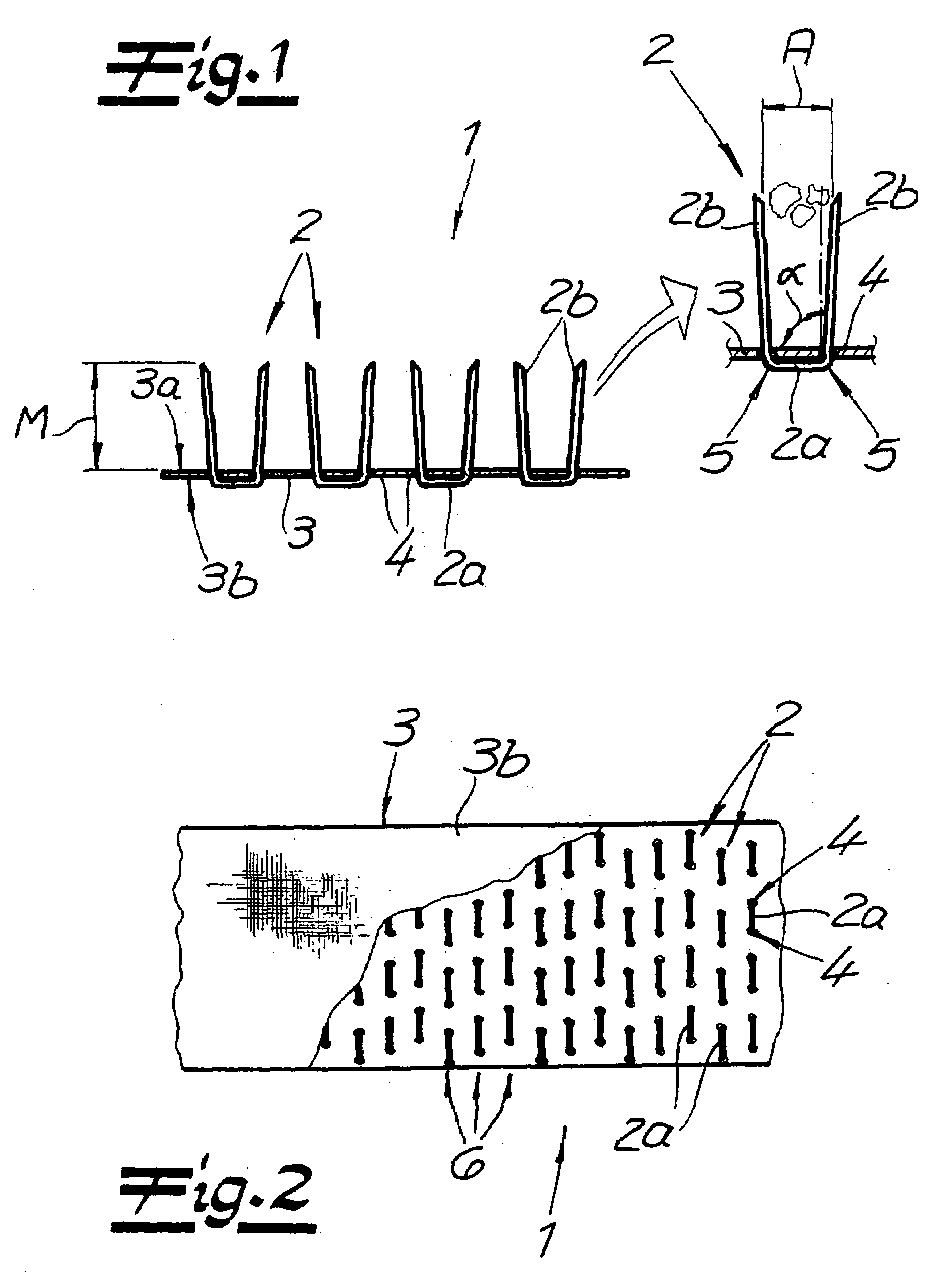

[0021]Referring now in detail to the drawings, the figures show a brush belt 1, which has several bristles 2, which are anchored in a belt body 3. Bristles 2 are produced completely from plastic such as polyamide (PA), acryl nitrile butadiene styrene (ABS), polycarbonate (PC), polyethylene (PE), polyethylene terephthalate (PET), polypropylene (PP), etc. Aside from the aforementioned thermoplastics, bristles 2 made of duroplastics are fundamentally also possible.

[0022]Bristles 2 are each configured in U shape, with a crosspiece 2a as the U base and two treatment legs 2b as the U shanks, in each instance. To produce the bristles 2, a standard injection-molding method can be used, which produces the bristles 2 in their form as shown right from the start. Then it is possible to place a supply of U-shaped bristles 2 into a magazine and to introduce them into belt body 3 using a punch.

[0023]Alternatively to this, however, bristles 2 can also be produced from a single strand of plastic tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com