Double-slope bridge expansion device

A telescoping device and double-slope technology, applied in the field of expansion joints, can solve the problems of easy water leakage, high cost, and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

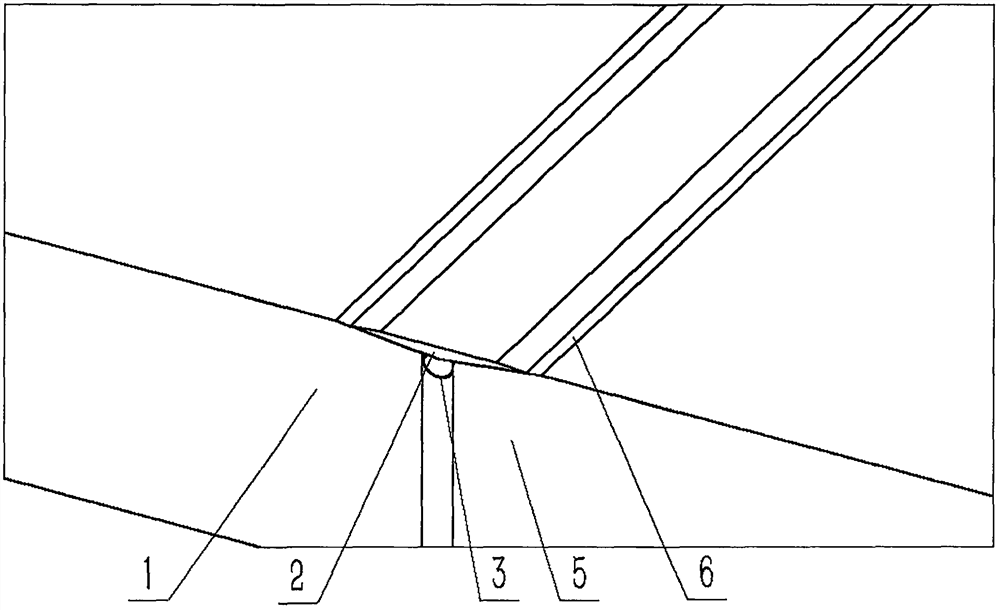

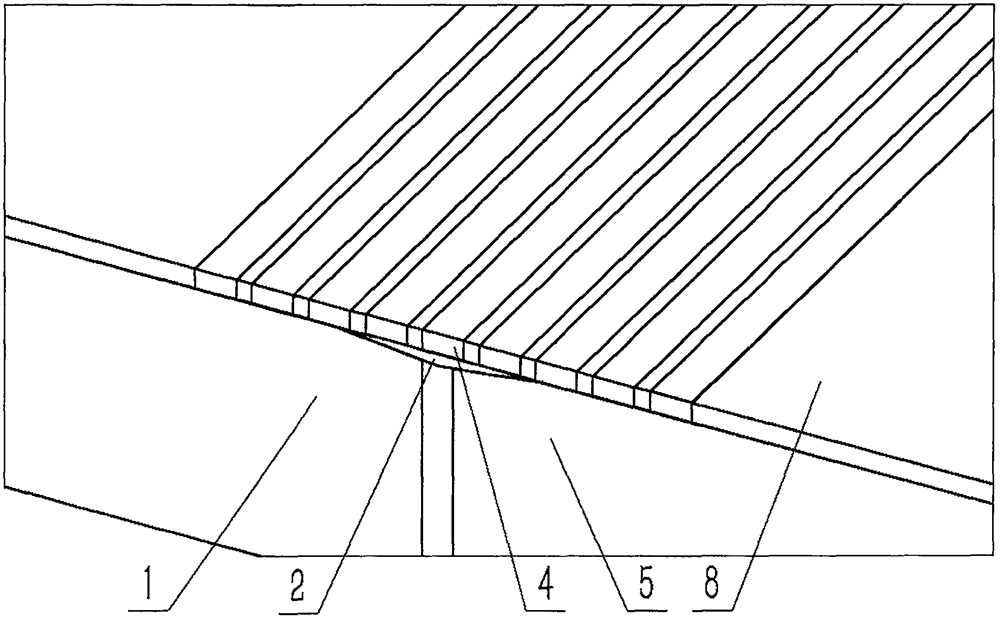

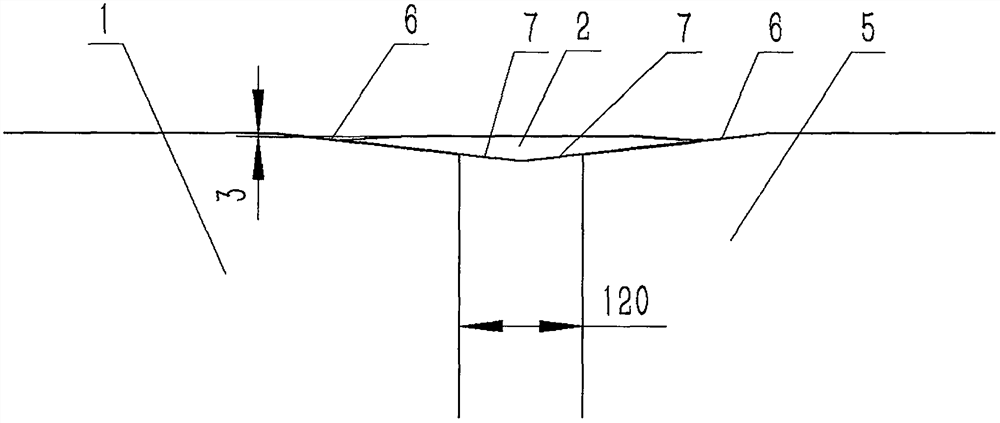

[0025] figure 1 and figure 2 It is respectively the schematic diagram of the end of the expansion device of the bridge under two different situations of double-slope cover plates (2) being placed on the top and placed below. In practical application, when the double-slope cover plate (2) is placed on top, the setting of the waterstop (3) refers to the comb-tooth bridge telescopic device, and this figure only shows the approximate position of the waterstop. When the double-slope cover is lowered, the telescopic panel is tilted to achieve the purpose of water resistance and waterproofing. In this manual, for the convenience of understanding, the non-warped head is taken as an example for illustration.

[0026] figure 1 The situation where the double-slope cover plate of the present invention is placed on top is shown. This setting method is suitable for motor vehicle lanes, where a large number of heavy-duty vehicles pass, and has the advantage of a simple structure and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com