Dust isolating device for coal blasting mining

A technology of dust isolation and installation board, applied in safety devices, dustproof, mining equipment, etc., can solve the problems of hidden dangers of mine workers, dust diffusion affecting safe production in mining areas, and inability to effectively handle coal mine dust, and achieve easy transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

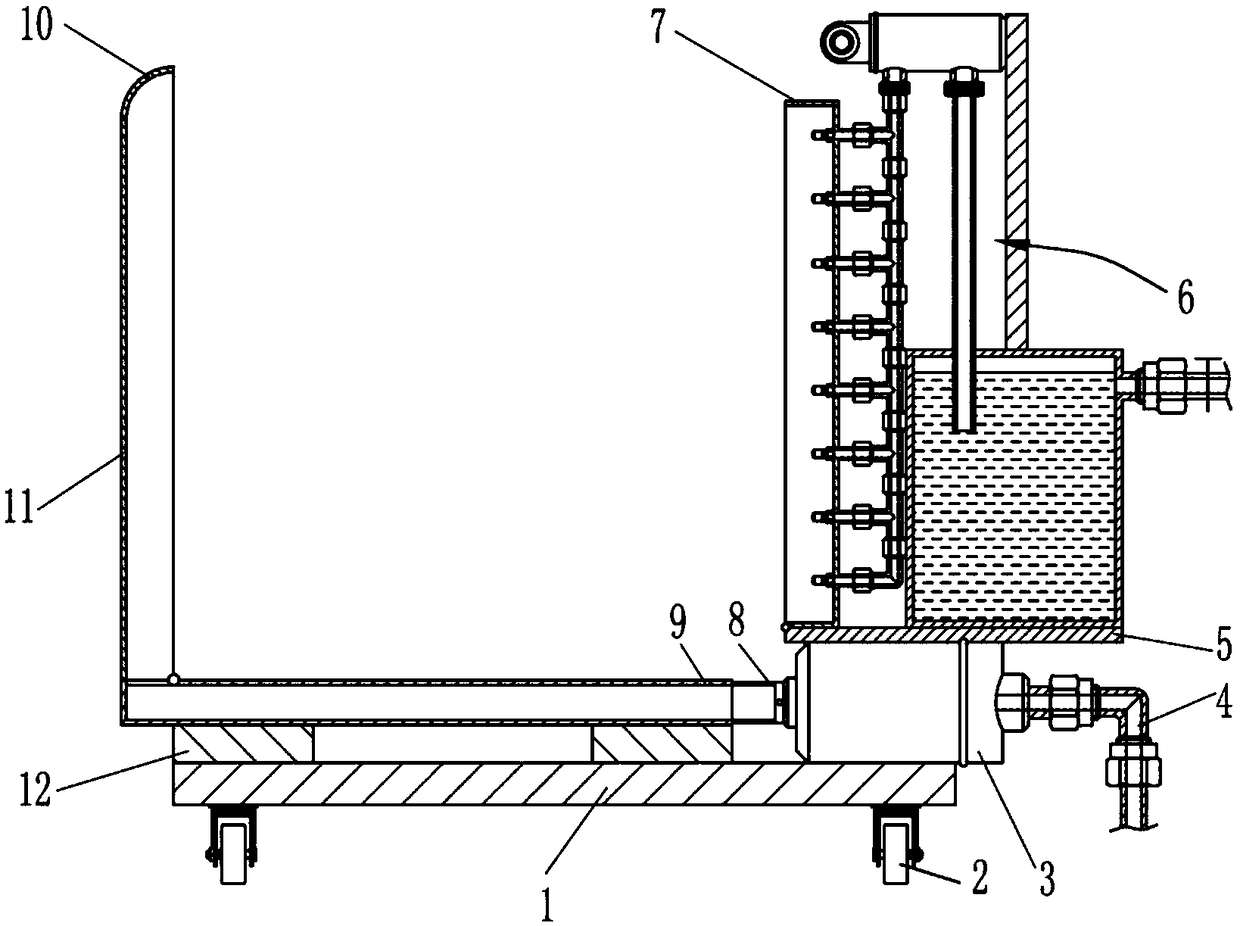

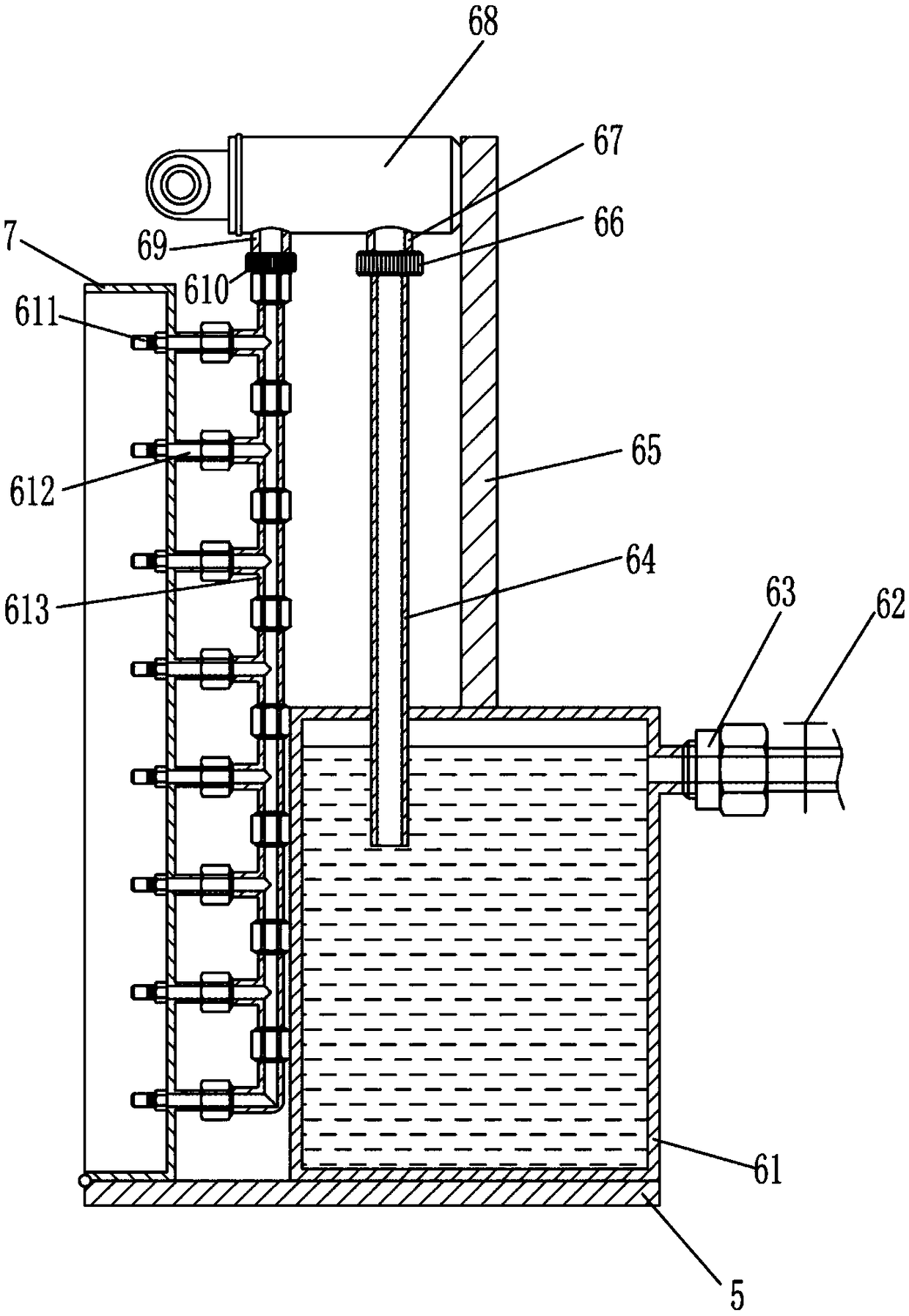

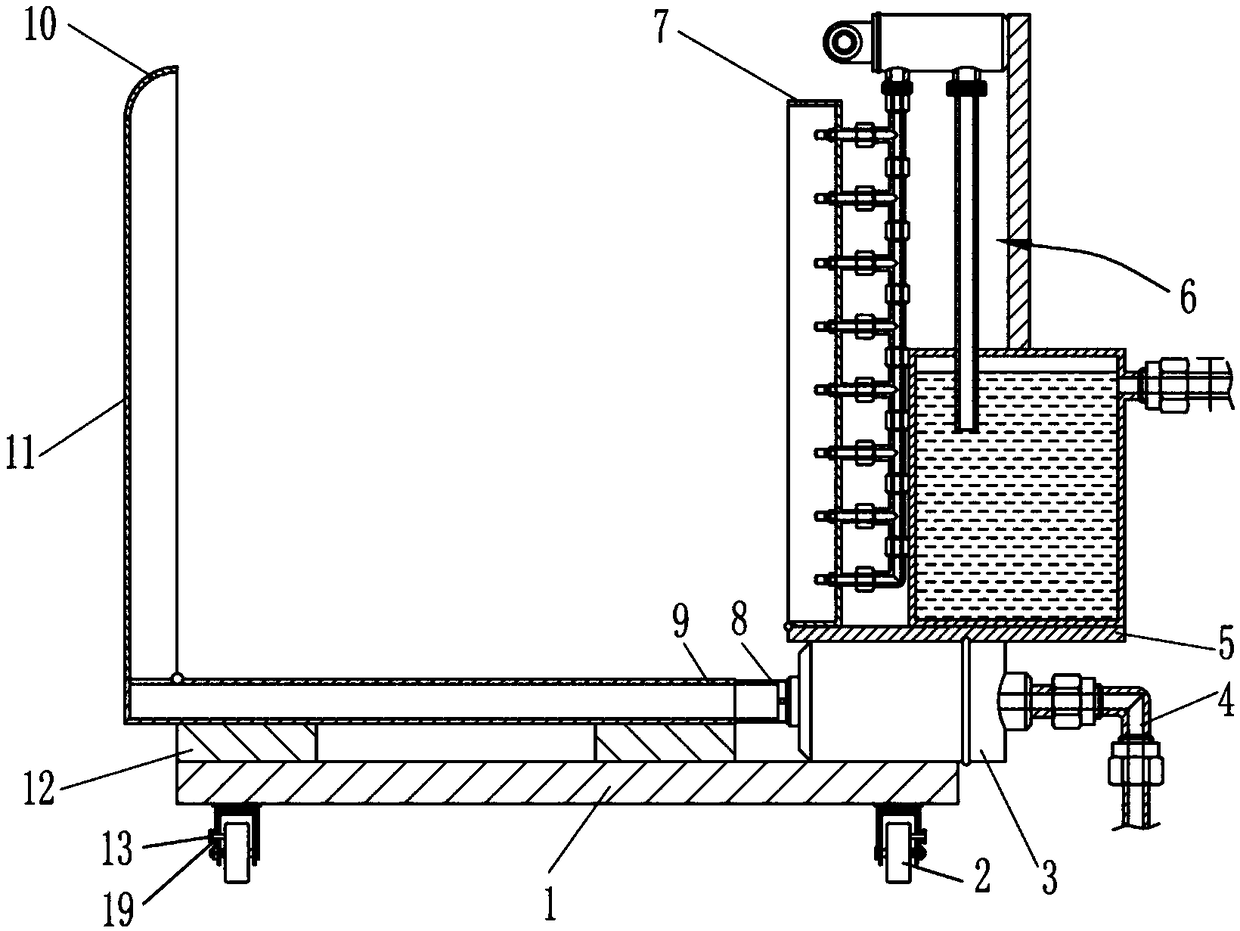

[0023] A dust isolation device for blasting coal mining, such as Figure 1-6 As shown, it includes a first mounting plate 1, a wheel 2, a hydraulic cylinder 3, a drain pipe 4, a second mounting plate 5, a spray mechanism 6, a flow plate 7, a first connecting pipe 8, a sewage pipe 9, and a guide groove 10 , the confluence groove 11 and the connecting plate 12; the wheel 2 is fixedly connected to the bottom of the first mounting plate 1, and the hydraulic cylinder 3 is fixed to the top side of the first mounting plate 1; the drain pipe 4 is fixedly connected to the output end of the hydraulic cylinder 3, and the drain The pipe 4 communicates with the hydraulic cylinder 3; a plurality of connecting plates 12 are fixedly connected to the top of the first installation plate 1, and the sewage pipe 9 is fixedly connected to the top of the connecting plate 12; one end of the first connecting pipe 8 communicates with the sewage pipe 9, and the other end It communicates with the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com