A grooved series multi-stage pressure reducing regulating valve

A pressure-reducing regulating valve, grooved technology, applied in the direction of lift valve, valve details, valve device, etc., can solve problems such as movement jam, fluid short circuit, easy to block flow channel, etc., achieve high strength and shock resistance, eliminate Noise and vibration, flash suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

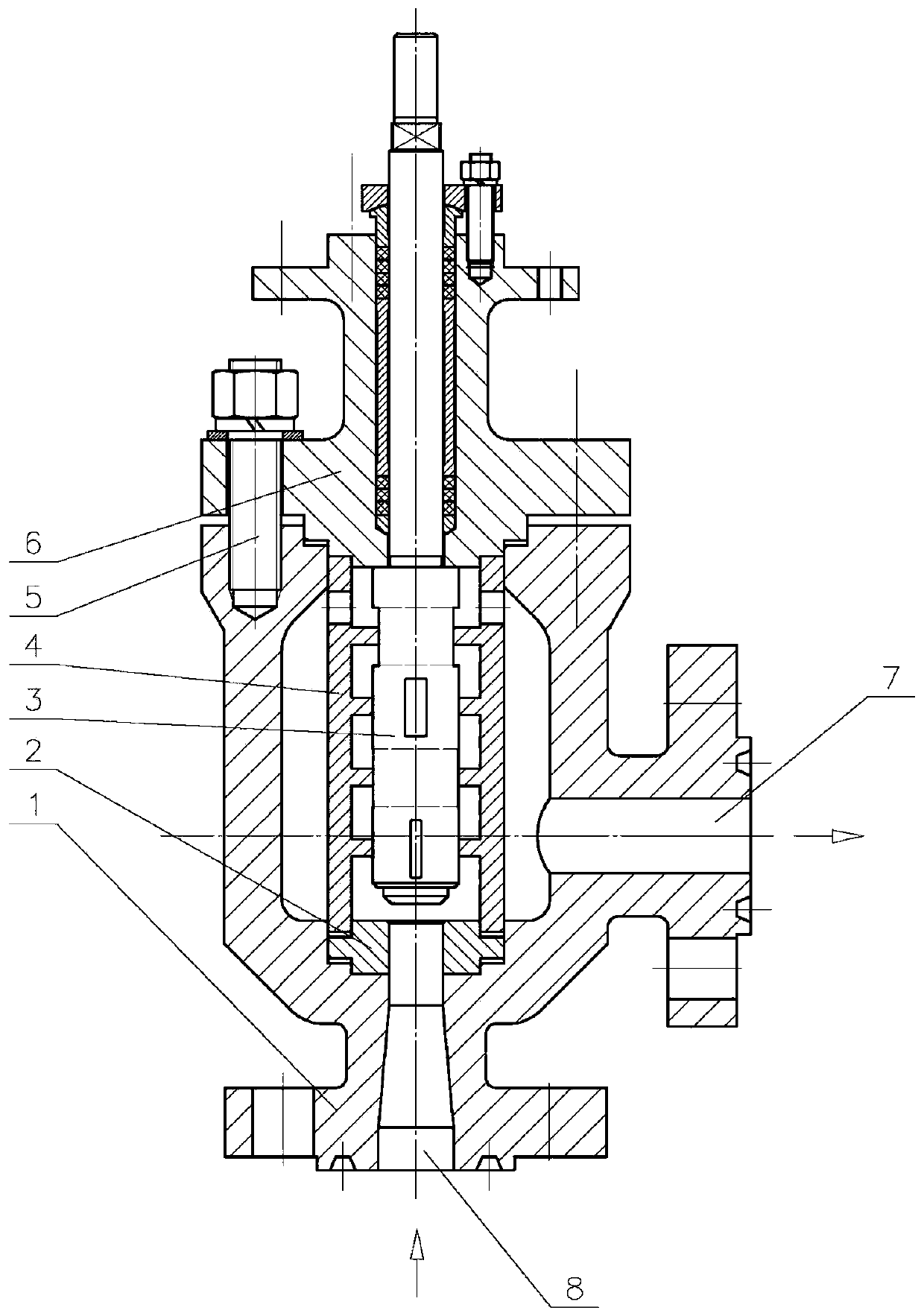

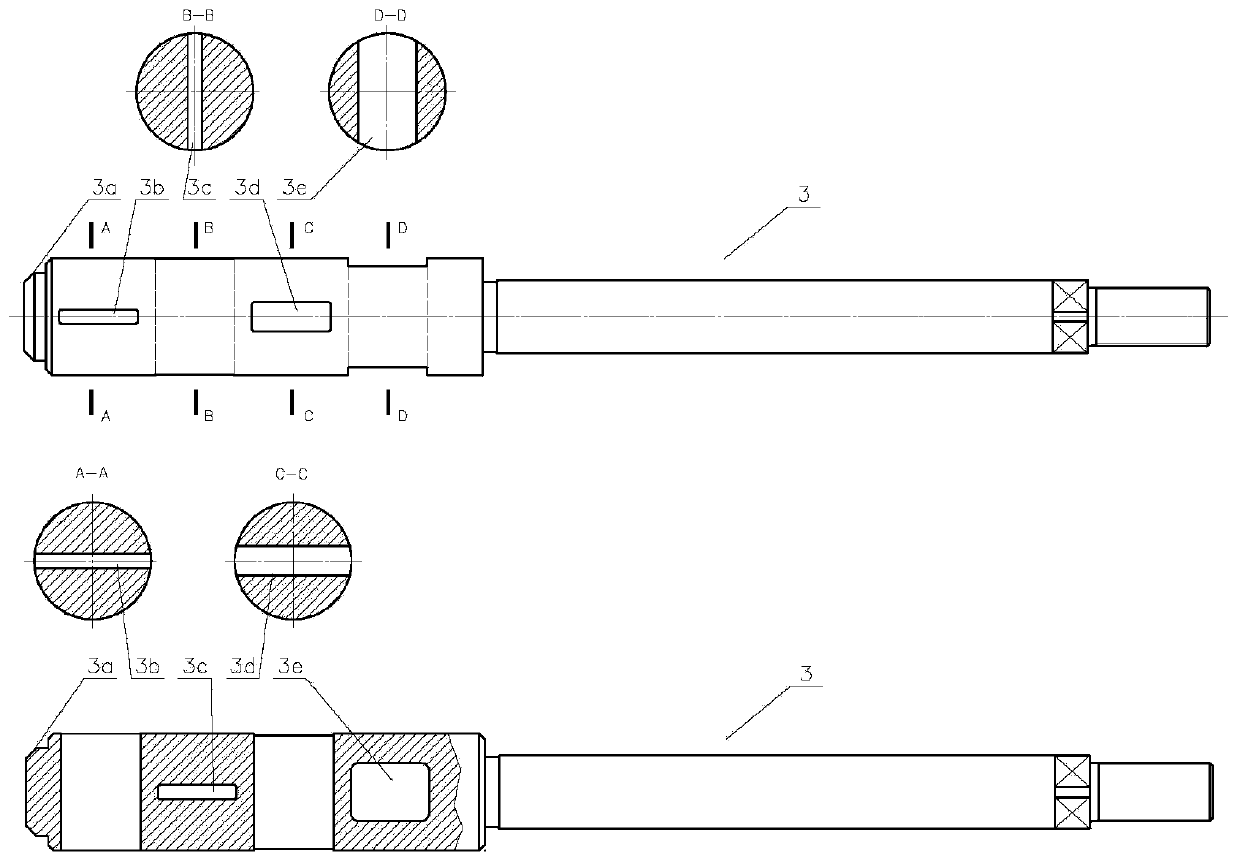

[0028] like figure 1 , 2 As shown, this specific embodiment is a grooved series multi-stage pressure reducing regulating valve, which is a series four-stage pressure reducing regulating valve, including a valve body 1, and a cavity formed by the valve body 1 and the valve cover 6 is provided with a pressure reducing valve. Energy chamber 4 and valve seat 2; through the middle flange fastening bolt 5 between the valve cover 6 and the valve body 1, the energy dissipation chamber 4 is tightly pressed between the valve cover 6 and the valve seat 2; the inner wall of the energy dissipation chamber 4 There are four-stage rib plates at equal intervals, and the end of the energy dissipation chamber 4 close to the valve cover 6 is provided with diversion holes 4e uniformly distributed in the circumferential direction; The grooved valve core 3 is slidably matched with the four-stage rib on the inner wall of the energy dissipation chamber 4 , and the rib precisely guides the grooved val...

Embodiment 2

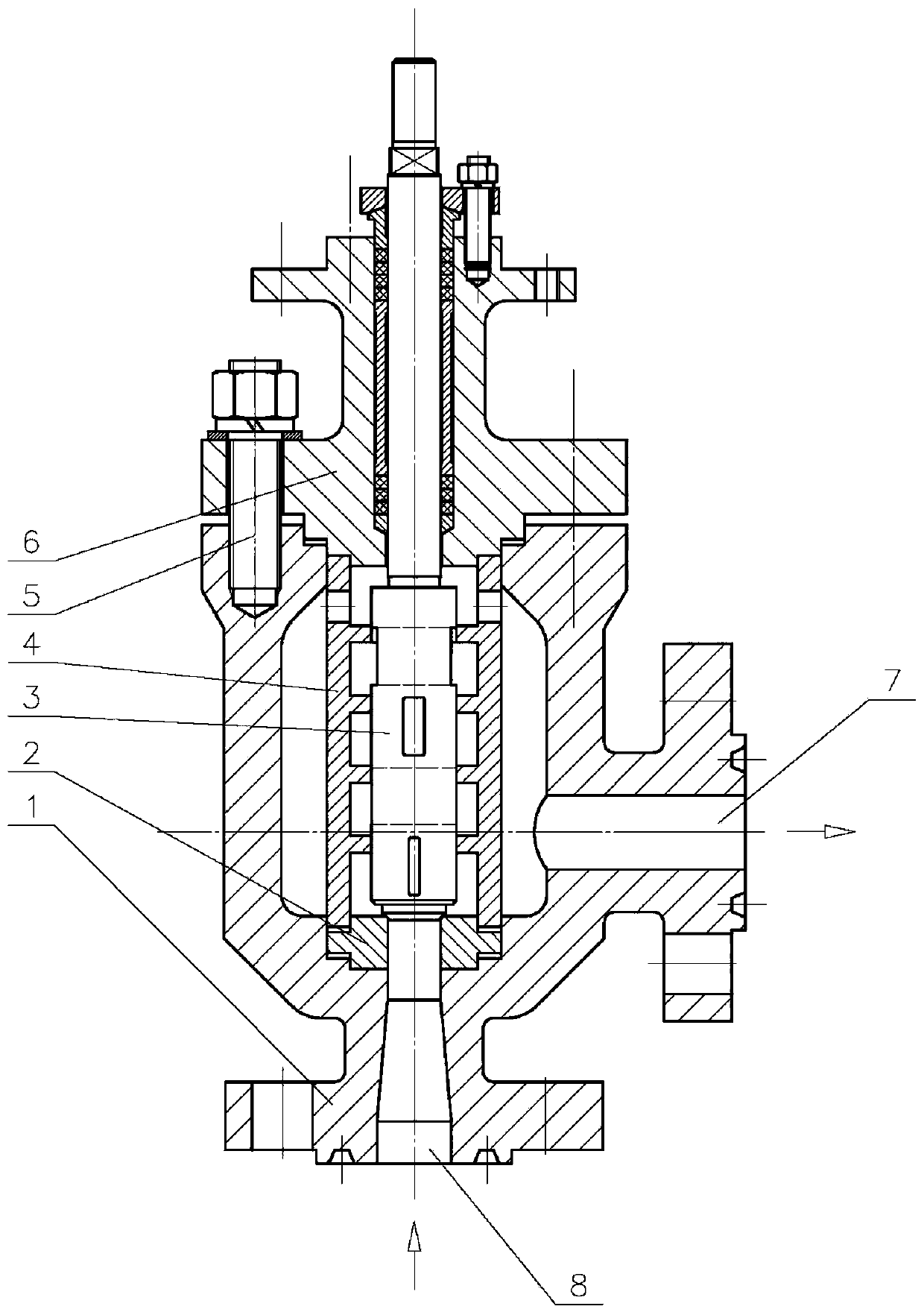

[0033] The difference between this embodiment and Embodiment 1 is that the decompression groove is non-penetrating; the structure diagram of the grooved series multi-stage decompression regulating valve in the fully open state, and the structure of the grooved series multistage decompression regulating valve in the closed state The schematic diagram and the schematic diagram of the grooved valve core structure are as follows Figure 4 , 5 , 6 shown.

[0034] The grooved series-connected multi-stage pressure-reducing regulating valves in Example 1 and Example 2 are all series-connected four-stage pressure-reducing regulating valves. Except for the four-stage pressure-reducing regulating valve, the grooved series-connected multi-stage pressure-reducing regulating valve in the present invention is The regulating valve can also be a two-stage, three-stage, five-stage and more than five-stage regulating valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com