A kind of testing equipment for thermal insulation performance of doors and windows

A thermal insulation performance, door and window technology, applied in the field of door and window thermal insulation performance testing equipment, can solve problems such as heat and cold air cannot be collected, surface wear of doors and windows, troublesome operation, etc., to achieve efficient and stable fixation, energy saving, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

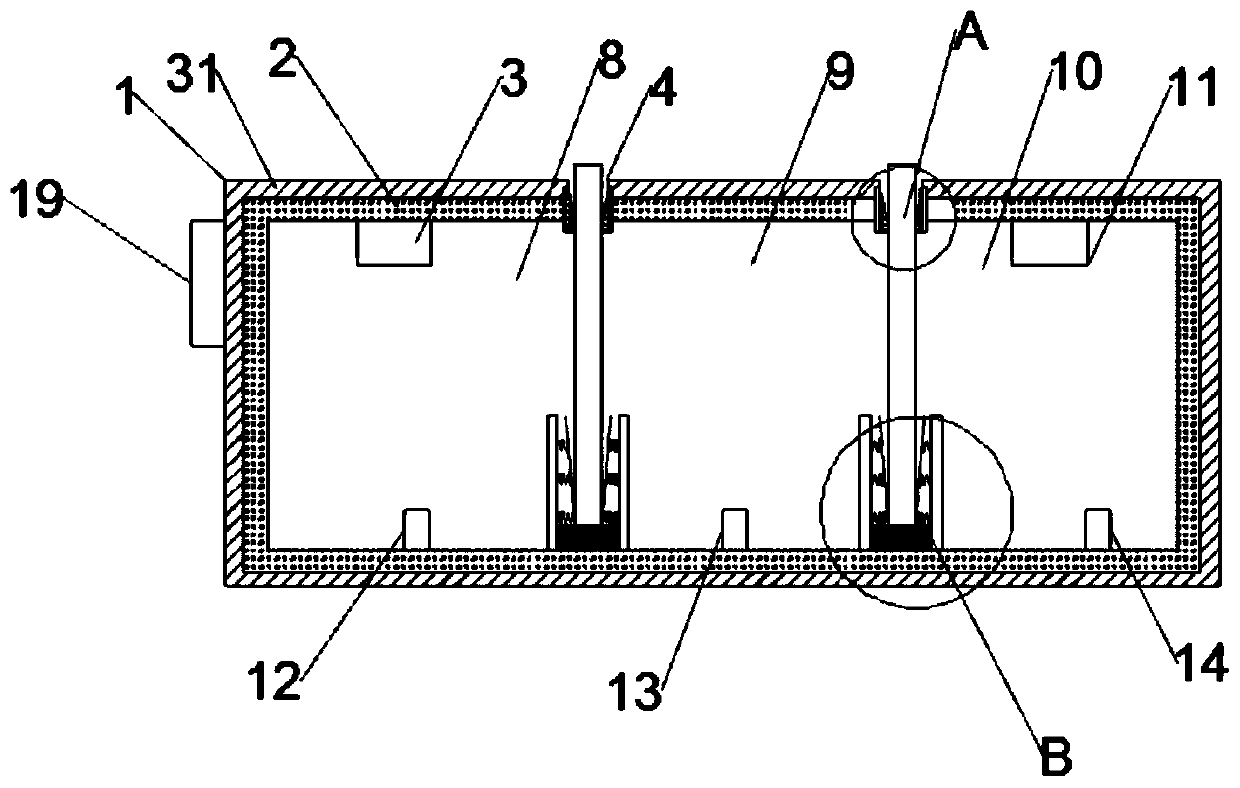

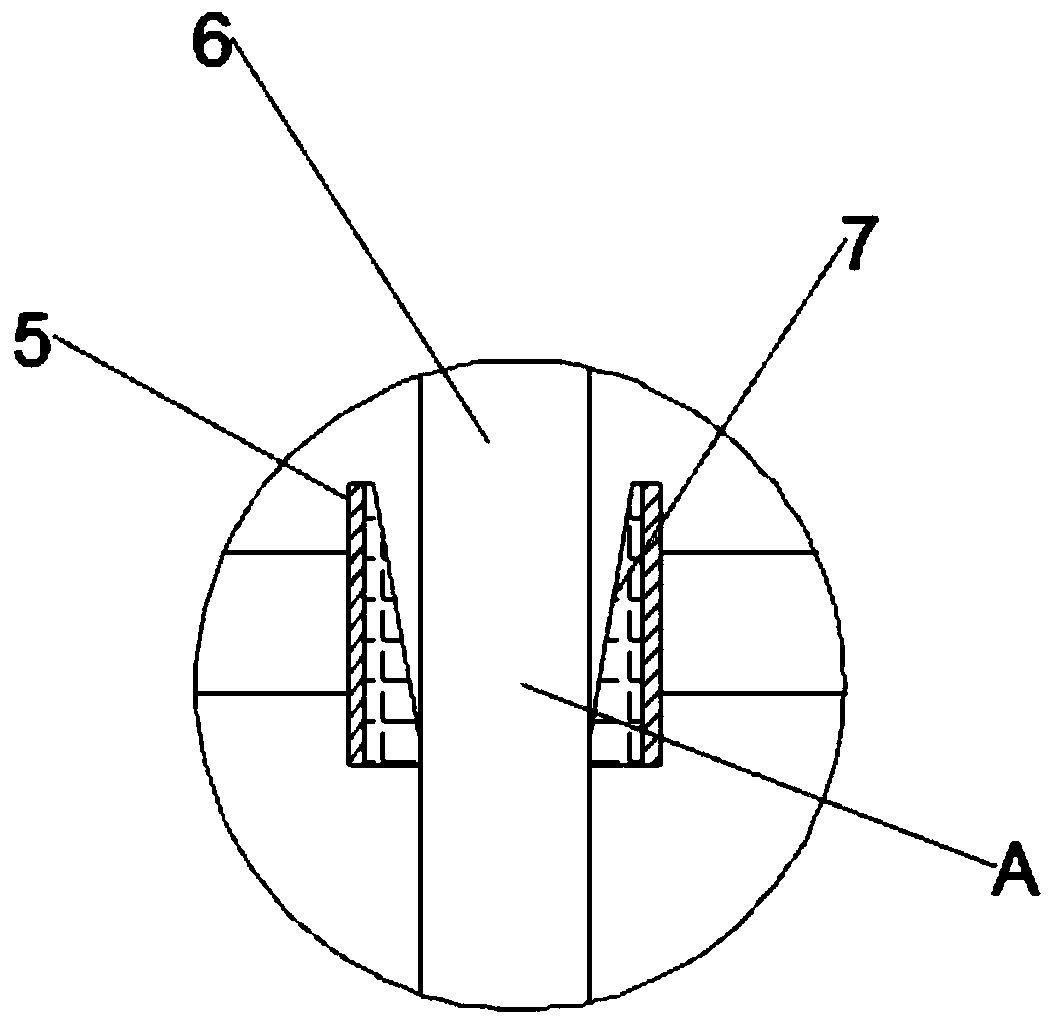

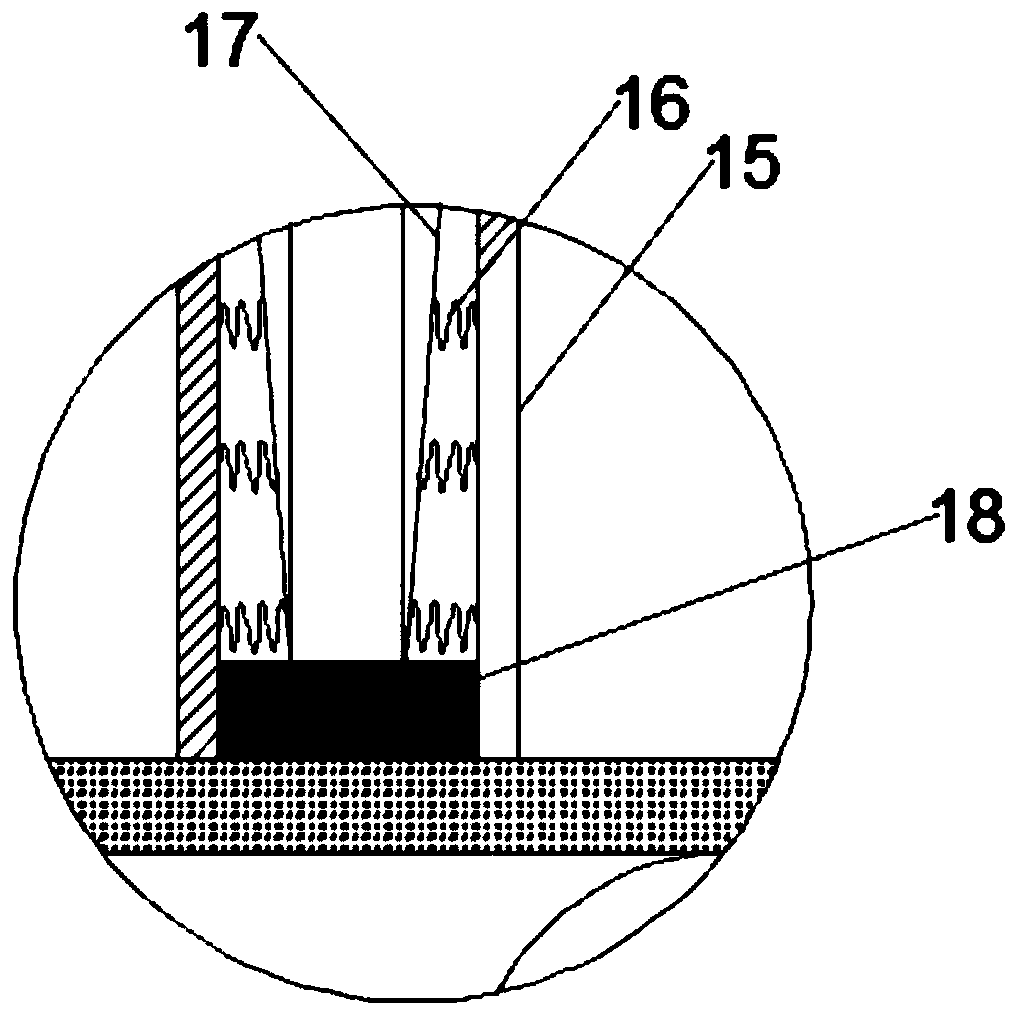

[0026] see Figure 1~6 , in an embodiment of the present invention, a door and window insulation performance testing equipment, including a main body 1, a heating zone 8, a normal temperature zone 9 and a cooling zone 10, the inside of the main body 1 is provided with a heating zone 8 and a normal temperature zone 9 sequentially from left to right and the cooling zone 10, the main body 1 is composed of a cooling fan control switch 21 and a heat insulation layer 2, the heat insulation layer 2 is arranged on the inner side of the shell 31, and the inside of the heat insulation layer 2 is provided with B1 grade rubber and plastic, fully Heat insulation, the top of the heating zone 8 is fixedly connected to the inner surface of the middle part of the heat insulation layer 2 with a heating rod 3, the model of the heating rod 3 is FRX-A01, and the heating rod 3 is made of stainless steel. The pipe diameter of the heating rod 3 is 10-22 mm, and the top of the cooling zone 10 is fixed...

Embodiment 2

[0028] see Figure 1~6, in an embodiment of the present invention, a door and window insulation performance testing equipment, including a main body 1, a heating zone 8, a normal temperature zone 9 and a cooling zone 10, the inside of the main body 1 is provided with a heating zone 8 and a normal temperature zone 9 sequentially from left to right and the cooling zone 10, the main body 1 is composed of a cooling fan control switch 21 and a heat insulation layer 2, the heat insulation layer 2 is arranged on the inner side of the shell 31, and the inside of the heat insulation layer 2 is provided with B1 grade rubber and plastic, fully Heat insulation, the top of the heating zone 8 is fixedly connected to the inner surface of the middle part of the heat insulation layer 2 with a heating rod 3, the model of the heating rod 3 is FRX-A01, and the heating rod 3 is made of stainless steel. The pipe diameter of the heating rod 3 is 10-22 mm, and the top of the cooling zone 10 is fixedl...

Embodiment 3

[0031] see Figure 1~6 , in an embodiment of the present invention, a door and window insulation performance testing equipment, including a main body 1, a heating zone 8, a normal temperature zone 9 and a cooling zone 10, the inside of the main body 1 is provided with a heating zone 8 and a normal temperature zone 9 sequentially from left to right and the cooling zone 10, the main body 1 is composed of a cooling fan control switch 21 and a heat insulation layer 2, the heat insulation layer 2 is arranged on the inner side of the shell 31, and the inside of the heat insulation layer 2 is provided with B1 grade rubber and plastic, fully Heat insulation, the top of the heating zone 8 is fixedly connected to the inner surface of the middle part of the heat insulation layer 2 with a heating rod 3, the model of the heating rod 3 is FRX-A01, and the heating rod 3 is made of stainless steel. The pipe diameter of the heating rod 3 is 10-22 mm, and the top of the cooling zone 10 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com