Collecting and manufacturing method of sandy soil 1m original-state whole-section specimen

A sandy soil and sample technology, applied in the field of soil sample collection and production, can solve the problems of unsuitable sandy soil types, loose, easy to collapse, and no firmness of sandy soil types, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

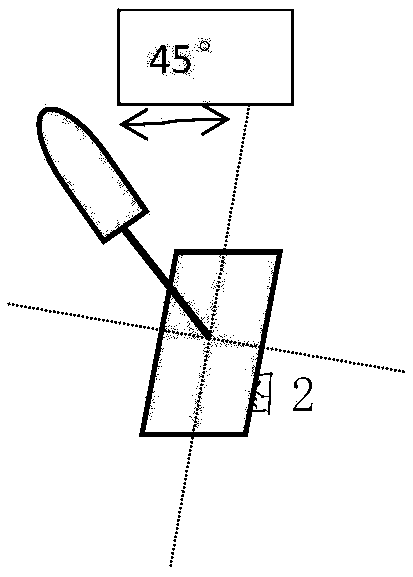

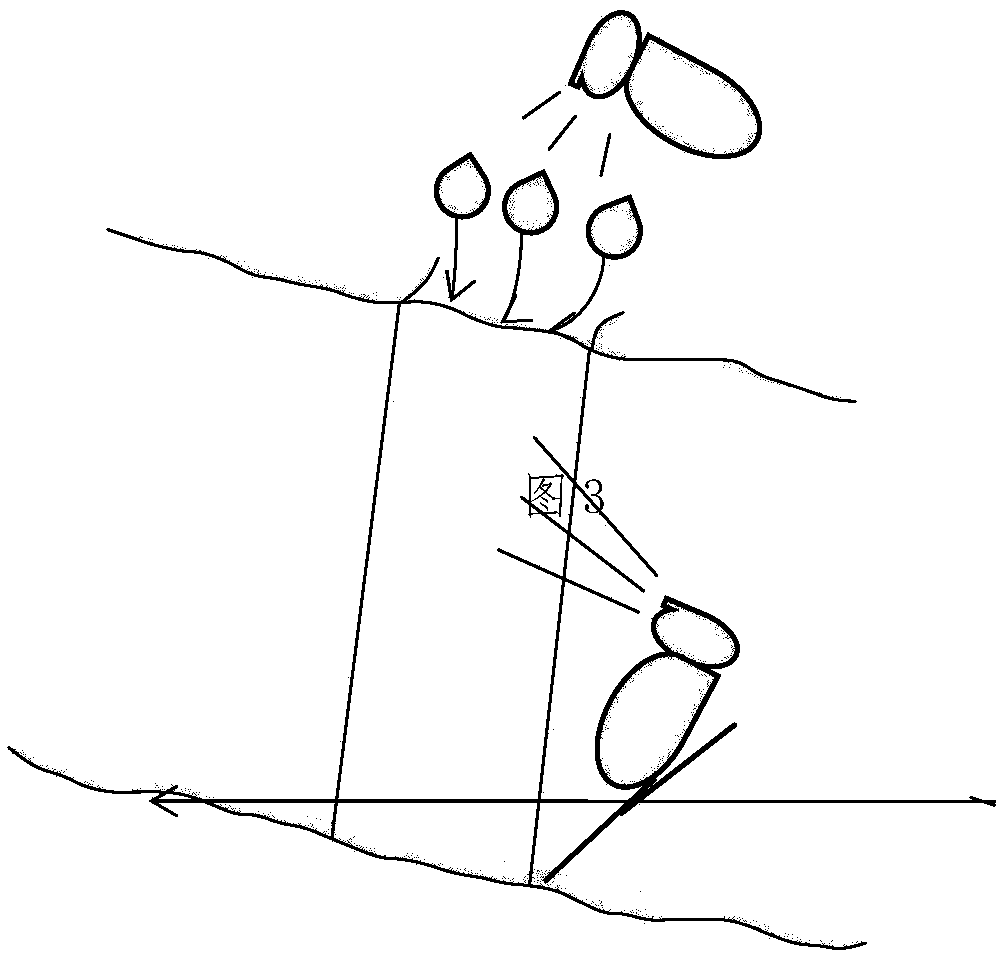

[0034] Such as Figure 1-4 shown.

[0035] The invention discloses a collection and production method of a 1 m whole section of sandy soil, which includes the collection technology of spraying and coagulating the soil body and the production technology of blowing sand by wind. The method for coagulating the soil by spraying glue is to gently draw the outline of the soil column to be collected, spray the soil with a specified proportion of glue, and wait for the soil to dry out and condense. When drawing the outline of the soil column, the mold made of wooden boards is used to lean against the natural surface, and the line is drawn with a knife to obtain the outline of the soil. Glue spraying through the soil refers to spraying glue on the marked soil, up and down, left and right, including the central part. Soil coagulation means that after the spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com