Feeding device on linear screen box

A technology of linear sieve and sieve box, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of low production capacity and small utilization area of screen mesh, and achieve the effect of simple structure, convenient assembly and installation, and large utilization area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

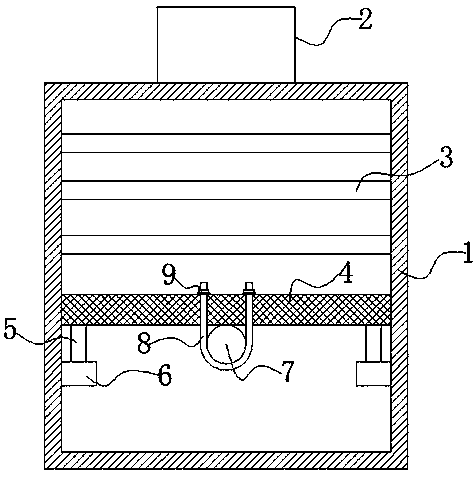

[0008] like figure 1 As shown, the present invention discloses a feeding device on a linear screen box, including: a screen box 1, a feed inlet box 2, a buffer bar 3, a linear screen 4, a rubber pillar 5, a support seat 6, and a bottom beam 7 , U-shaped ferrules 8, lock nuts 9, the top surface of the screen box 1 is fixedly installed with a feed inlet box 2, and the inner top of the screen box 1 is installed below the feed inlet box 2 A plurality of buffer bars 3 are provided, and a plurality of buffer bars 3 are evenly spaced up and down, and a linear screen 4 is installed inside the screen box 1 and below the buffer bar 3, and the straight line The bottom surfaces of both sides of the screen 4 are supported and fixed by a plurality of rubber pillars 5 provided. The rubber pillars 5 are fixedly installed on the support base 6, and the support base 6 is fixedly welded and connected to the inner wall of the screen box 1. The middle position of the bottom surface of the linear ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap