Hydraulic ejecting type mounting in-place method for generator of large gas turbine

A technology of generators and hydraulic jacks, applied in the direction of supporting machines, mechanical equipment, engine bases, etc., to achieve the effect of simple mechanical equipment, simple operation methods, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly illustrate the technical features of the present solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings. It should be noted that components illustrated in the figures are not necessarily drawn to scale. Descriptions of well-known components and techniques are omitted herein to avoid unnecessarily limiting the present invention.

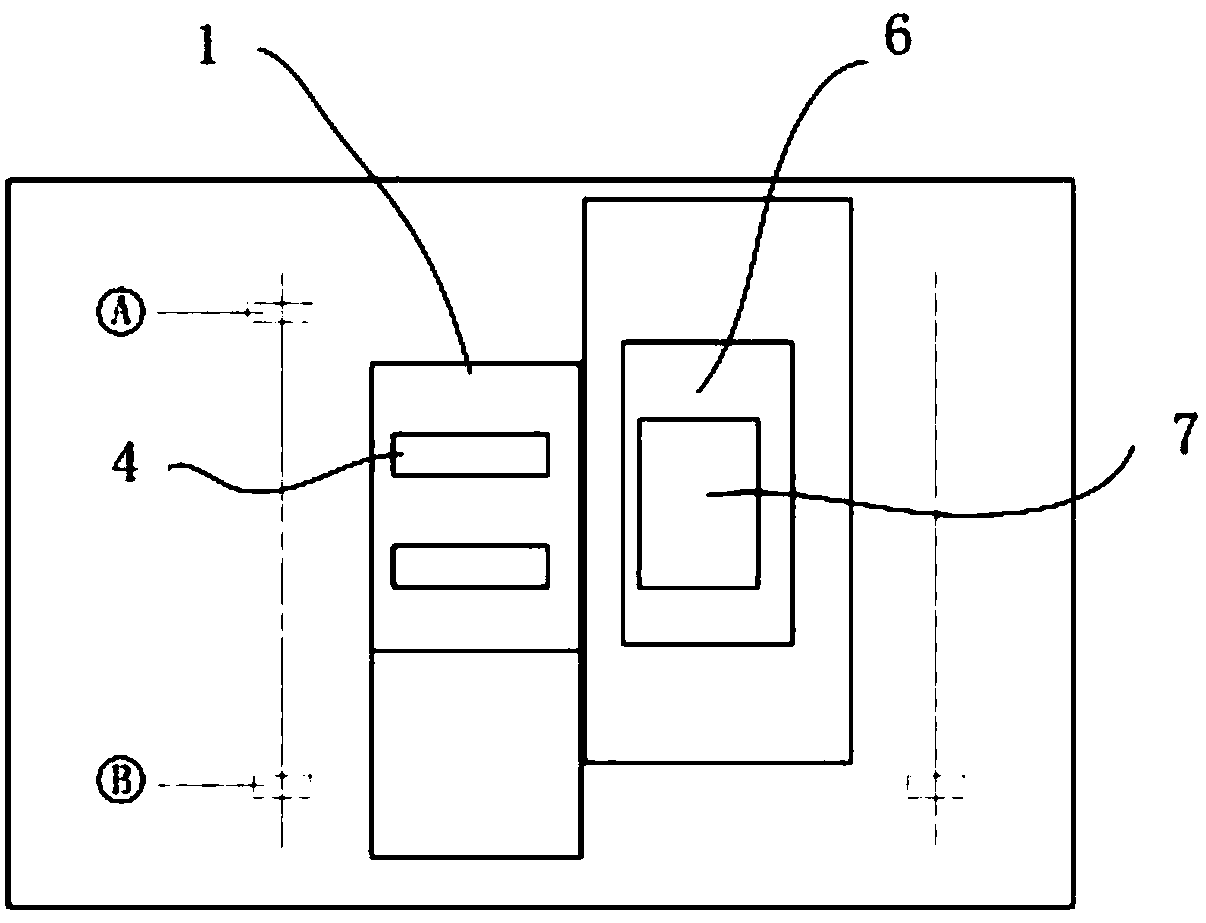

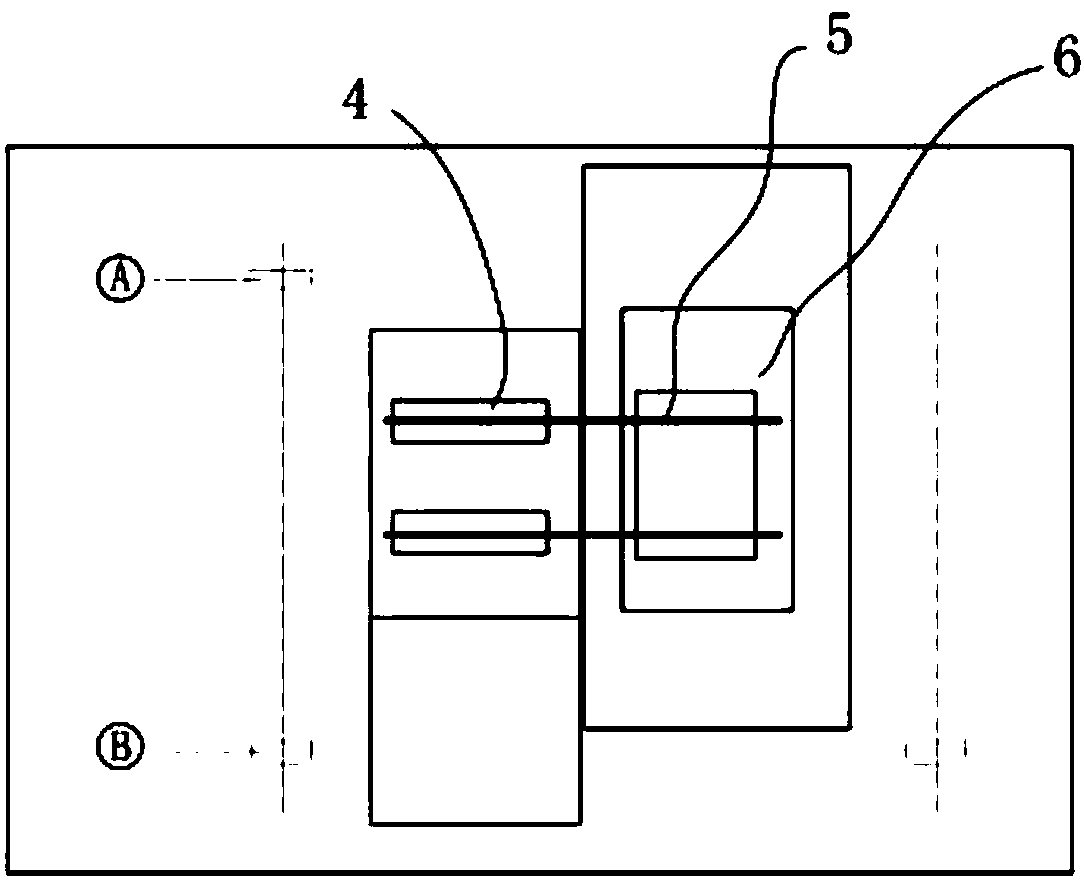

[0025] A method for hydraulic push-type installation and placement of a large gas turbine generator includes the following steps.

[0026] 1. Generator foundation backfill

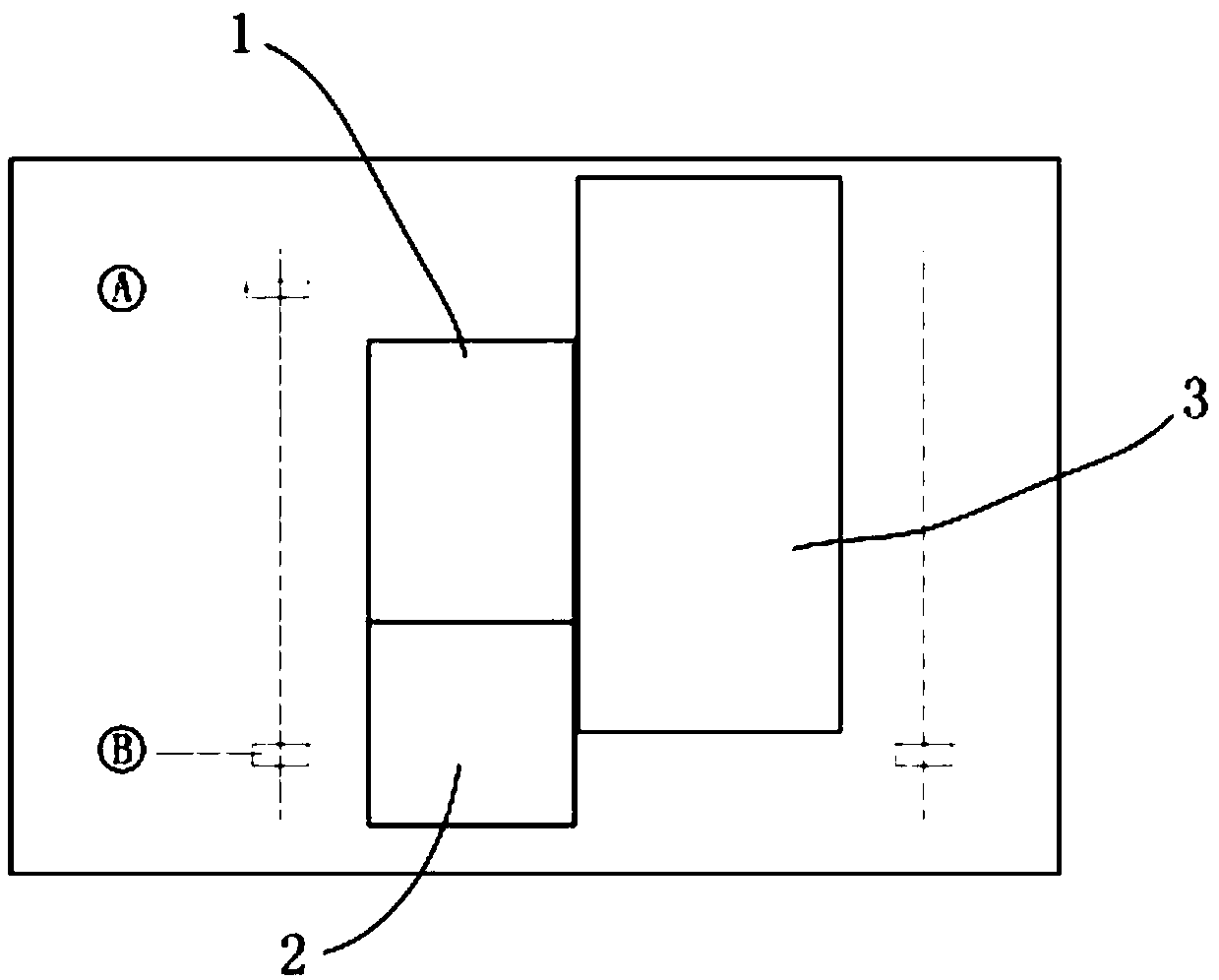

[0027] Such as figure 1 As shown, the base area 1 of the generator is located beside the base area 2 of the gas turbine. Backfill the longitudinal side of the generator foundation area 1 to the specified height and compact it, so as to ensure that the bottom elevation of the generator 7 reaches the required elevation after the arrival of the generator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com