Sewage treatment draining pipe casing

A technology for sewage treatment and drainage pipes, which is applied in the field of pipe sleeves and can solve problems such as not easy clogging, affecting sewage filtration, and holes in the filter screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

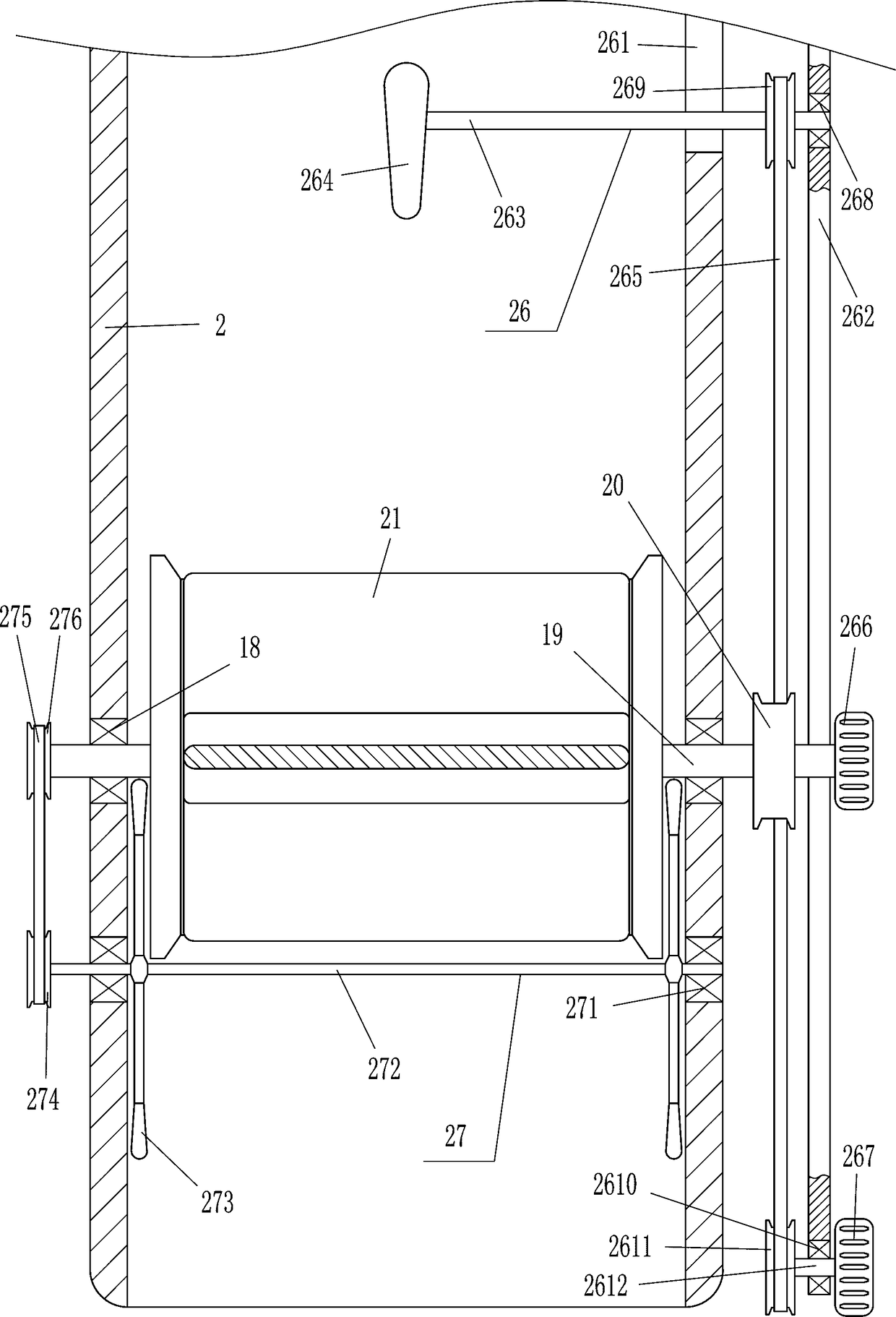

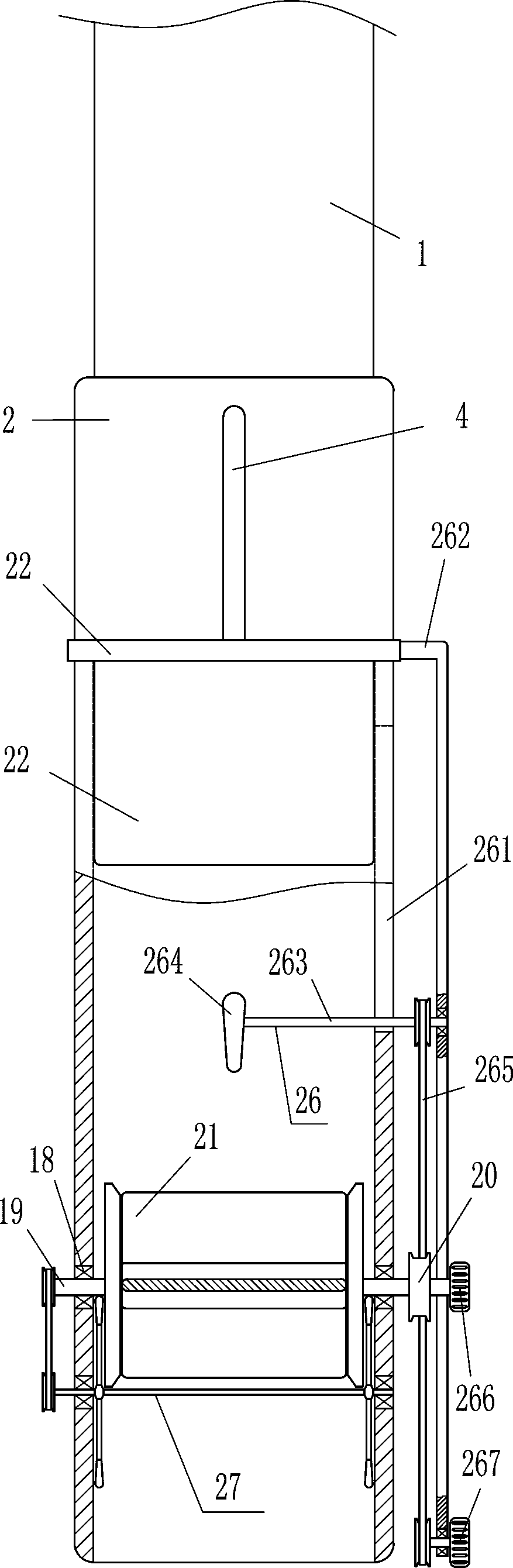

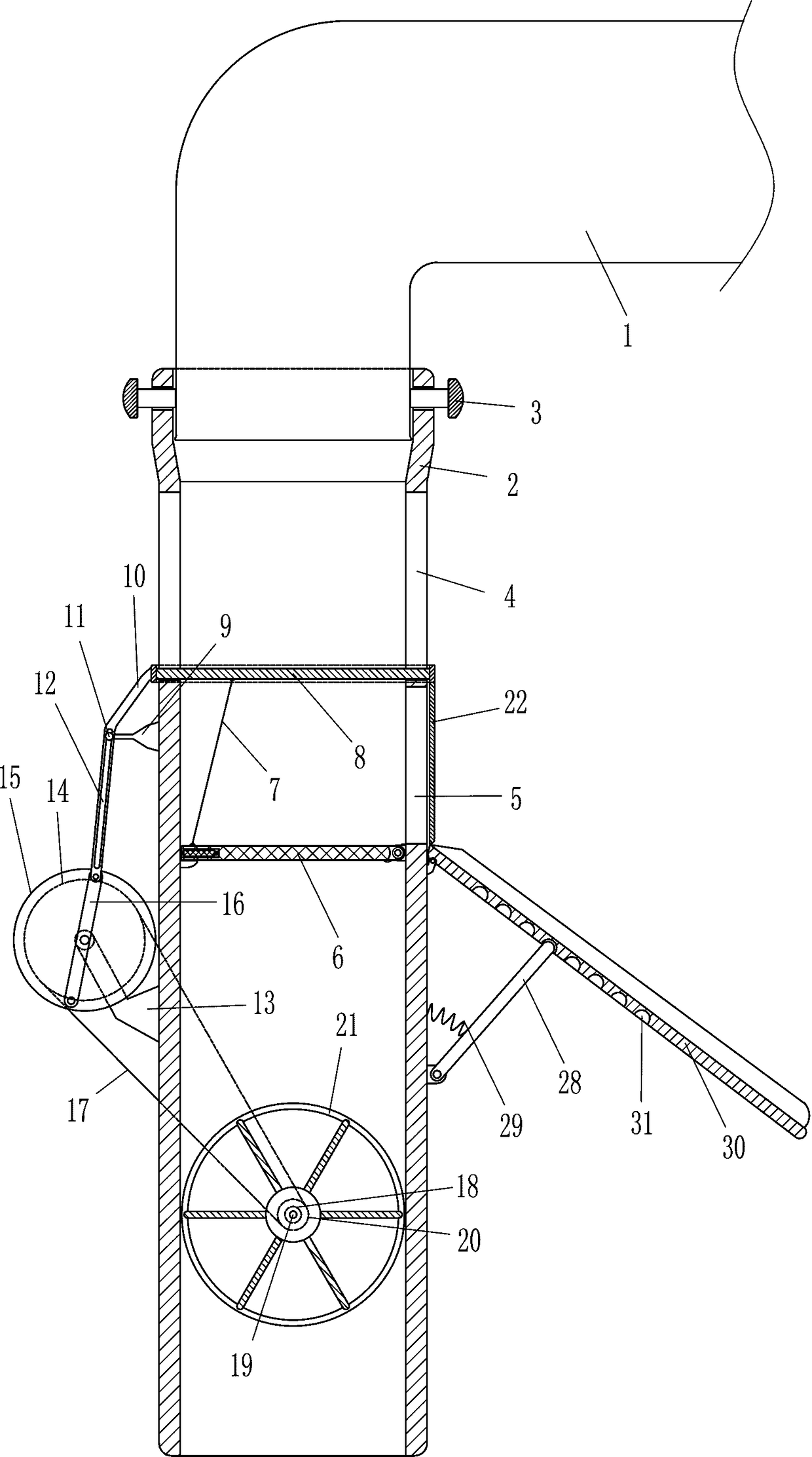

[0022] A sewage treatment drainage pipe sleeve, such as Figure 1-4 As shown, it includes a square casing 2, fastening bolts 3, first mesh plate 6, pull wire 7, cross bar 8, mounting seat 9, movable bar 10, roller 11, support seat 13, large pulley 14, turntable 15 , connecting rod 16, the first flat belt 17, the first bearing seat 18, the first rotating shaft 19, the small pulley 20, the water wheel 21, the baffle plate 22, the block 23, the torsion spring 24 and the square frame 25, the square casing 2 The left and right sides of the upper part are symmetrically provided with fastening bolts 3, and the upper part of the square sleeve 2 is symmetrically opened with slotted holes 4 that play a guiding role. 8. A square frame 25 is fixedly connected between the left and right sides of the cross bar 8. The square frame 25 is set on the square casing 2. The bottom of the square frame 25 is open, and the right side of the bottom of the square frame 25 is fixedly connected with a ba...

Embodiment 2

[0024] A sewage treatment drainage pipe sleeve, such as Figure 1-4 As shown, it includes a square casing 2, fastening bolts 3, first mesh plate 6, pull wire 7, cross bar 8, mounting seat 9, movable bar 10, roller 11, support seat 13, large pulley 14, turntable 15 , connecting rod 16, the first flat belt 17, the first bearing seat 18, the first rotating shaft 19, the small pulley 20, the water wheel 21, the baffle plate 22, the block 23, the torsion spring 24 and the square frame 25, the square casing 2 The left and right sides of the upper part are symmetrically provided with fastening bolts 3, and the upper part of the square sleeve 2 is symmetrically opened with slotted holes 4 that play a guiding role. 8. A square frame 25 is fixedly connected between the left and right sides of the cross bar 8. The square frame 25 is set on the square casing 2. The bottom of the square frame 25 is open, and the right side of the bottom of the square frame 25 is fixedly connected with a ba...

Embodiment 3

[0027] A sewage treatment drainage pipe sleeve, such as Figure 1-4 As shown, it includes a square casing 2, fastening bolts 3, first mesh plate 6, pull wire 7, cross bar 8, mounting seat 9, movable bar 10, roller 11, support seat 13, large pulley 14, turntable 15 , connecting rod 16, the first flat belt 17, the first bearing seat 18, the first rotating shaft 19, the small pulley 20, the water wheel 21, the baffle plate 22, the block 23, the torsion spring 24 and the square frame 25, the square casing 2 The left and right sides of the upper part are symmetrically provided with fastening bolts 3, and the upper part of the square sleeve 2 is symmetrically opened with slotted holes 4 that play a guiding role. 8. A square frame 25 is fixedly connected between the left and right sides of the cross bar 8. The square frame 25 is set on the square casing 2. The bottom of the square frame 25 is open, and the right side of the bottom of the square frame 25 is fixedly connected with a ba...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap