Paying off-straightening-cleaning integrated system for steel wires

A steel wire and cleaning room technology, applied in straightening equipment, metal extrusion cleaning equipment, metal wire drawing, etc., can solve the problems of complex production process, long processing time, and many parts, and achieve reasonable and simple structure and low production cost. Low, to achieve the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

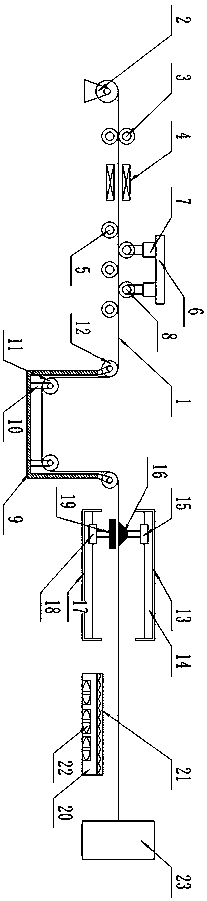

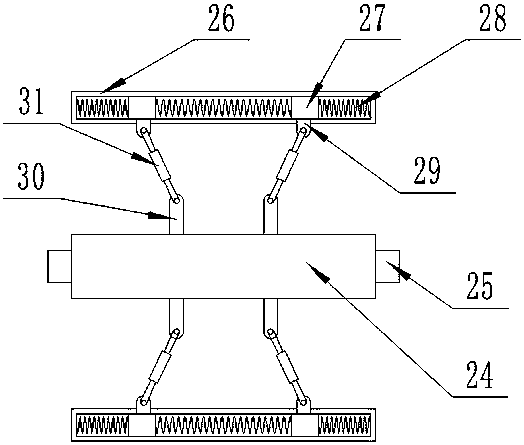

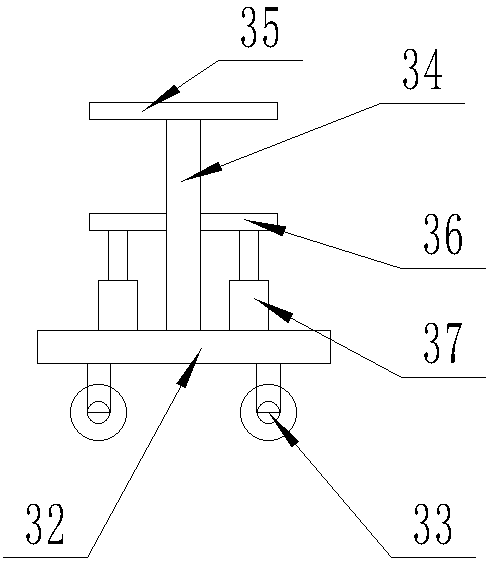

[0016] Such as Figure 1 to Figure 3 As shown, this specific embodiment adopts the following technical solutions: an integrated system for paying off, straightening and cleaning steel wires, including: a steel wire 1, and also includes a wire paying device 2, a guide wheel 3, a heater 4, a lower straightening wheel 5, and a top plate 6. Air pressure rod 7, upper correction wheel 8, cleaning chamber 9, roller mounting rod 10, lower roller 11, upper roller 12, upper casing 13, slide rail 14, upper slider 15, cleaning brush 16, lower casing 17 , lower slider 18, sponge 19, drying chamber 20, heating wire 21, blower fan 22 and take-up device 23; The right side of described pay-off device 2 is provided with two guide wheels 3 of upper and lower distribution; The right side of the guide wheel 3 is provided with two heaters 4 distributed up and down; the upper right side of the heater 4 is provided with two spaced upper correction wheels 8, and the upper correction wheels 8 are flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com