Power supplying and taking system of rail vehicle

A rail vehicle and electric system technology, applied in the field of power supply and power supply system, can solve the problems of vehicle power outage, negative impact on vehicle safety operation, power supply network load stability, continuous and stable power supply, etc., to achieve stable power supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

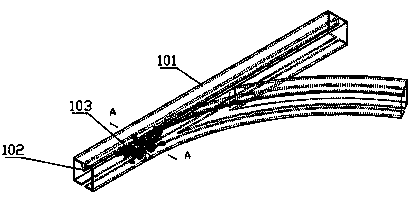

[0074] Embodiment 1, the guide rail 101 has a switch section and a non-switch section; the first power supply device 11 is continuously provided on the switch section and the non-switch section of the guide plate 102 . The first power supply device 11 is arranged along with the guide rail 101 along the entire running direction of the rail car 103 as the only power supply line. The first power supply device 11 is continuously arranged at the turnout and the non-turnout of the guide plate 102 . So that no matter where the rail car 103 is on the guide rail 101, the first power supply device 11 is in contact with the first power taking device 12, and the rail car 103 can obtain power supply.

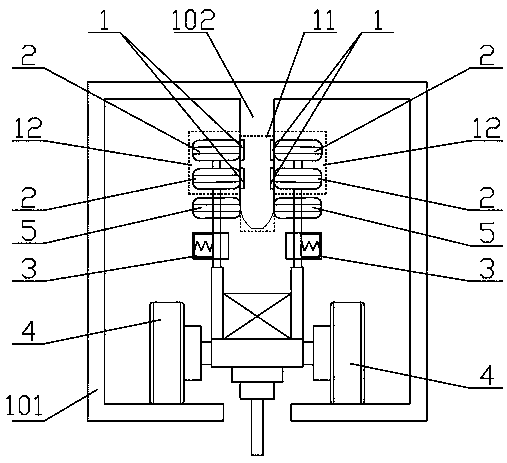

[0075] As preferred, such as figure 2 As shown, the first power supply device 11 includes at least two pairs of power supply contact rails 1, and at least one pair of power supply contact rails 1 are respectively positive and negative on the two opposite sides of the guide plate 102; One of...

Embodiment 2

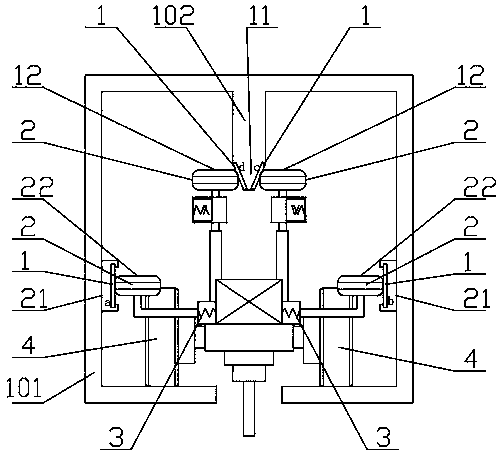

[0085] Embodiment 2, the second power supply device 21 is arranged along the entire guide rail 101 as the main power supply line. The first power supply device 11 is arranged at the switch as an auxiliary power supply line. It also includes a second power supply and power taking system, including a second power supply device 21, which is arranged on both sides of the inner wall of the guide rail 101 and arranged in parallel along the track of the guide rail 101; the second power taking device 22 is installed on the The two sides of the rail car 103; wherein, wherein, the second power taking device 22 can contact the second power supply device 21; the guide rail 101 has a switch section and a non-switch section; the first power supply The device 11 is arranged at least on the switch section of the guide plate 102 , and the second power supply device 21 is arranged at least on the switch section and the non-switch section of the guide plate 102 .

[0086] More specifically, the...

Embodiment 3

[0098] Embodiment 3, the first power supply device 11 and the second power supply device 21 are combined with each other, and both are arranged along the whole guide rail 101 . The second power supply and power taking system includes a second power supply device 21, which is arranged on both sides of the inner wall of the guide rail 101 and arranged in parallel along the track of the guide rail 101; the second power taking device 22 is installed on the track Both sides of the car 103; wherein, the second power-taking device 22 can contact the second power supply device 21 to obtain power;

[0099] Preferably, the first power supply device 11 includes a positive power supply contact rail 1 or a negative power supply contact rail 1; The power taking part 2; the second power supply device 21 includes the power supply contact rails 1 that are respectively arranged on both sides of the inner wall of the guide rail 101 and the polarity of the first power supply device 11 is opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com