Water-cooled motor casing gas seal detecting device

A detection device and water-cooled motor technology, which is applied in the direction of measuring the increase and decrease rate of the fluid, and using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of low detection efficiency, long time consumption, and heavy weight of the motor shell, etc., to achieve The effect of high detection efficiency, reduction of scrap rate and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

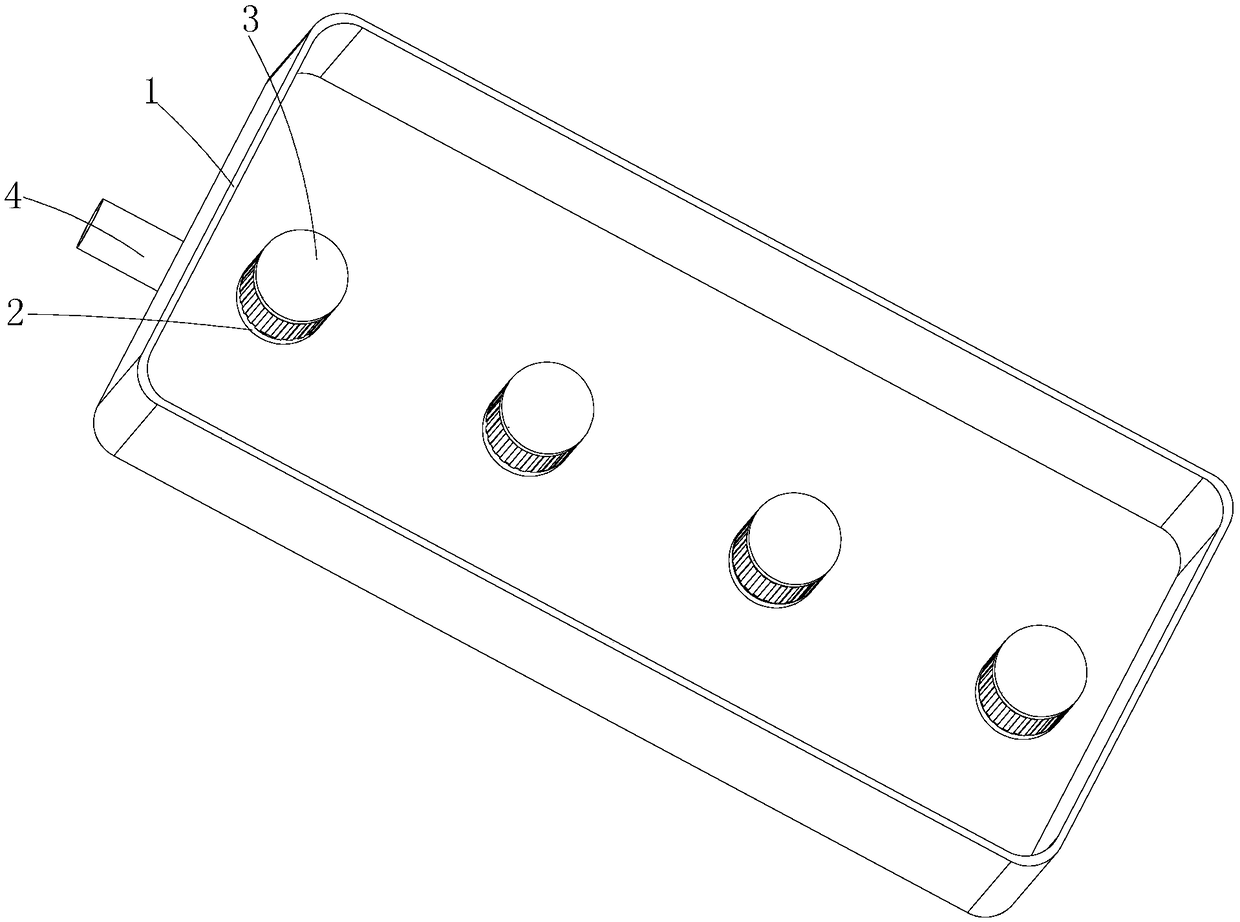

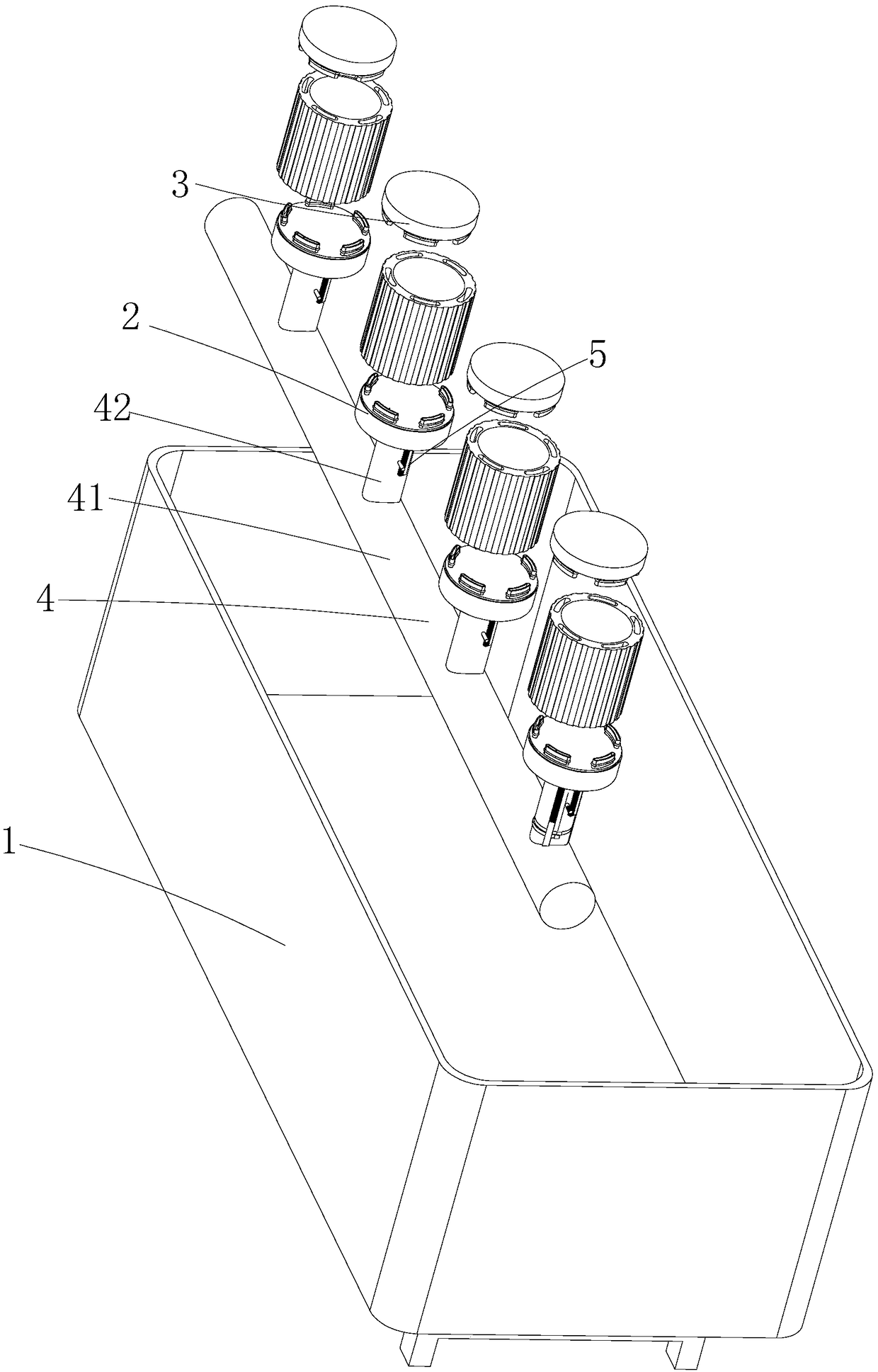

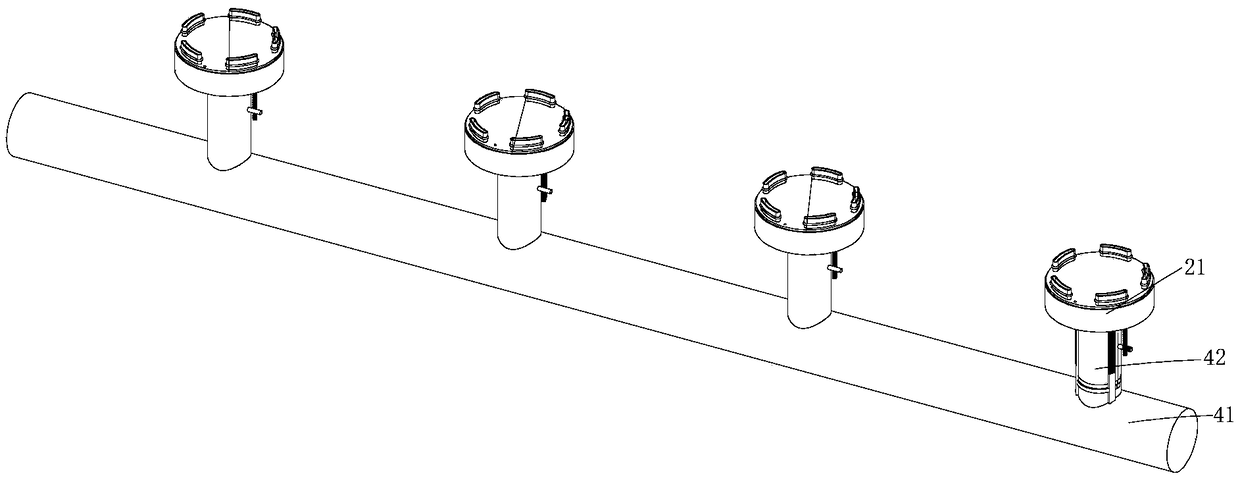

[0036] like Figure 1-10 As shown, a water-cooled motor casing air seal detection device includes a detection box 1, a first blocking part 2, a second blocking part 3, an air guide pipe 4 and an opening and closing structure 5, wherein the detection box 1 is made of metal box, the detection box 1 is filled with a detection liquid, the detection liquid can be water; the air guide pipeline 4 includes a main pipe 41 and a plurality of branch pipes 42, the main pipe 41 is a metal pipe, and the main pipe 41 is buried in the The bottom of the detection box 1, the branch pipe 42 is also a metal pipe, the branch pipe 42 is connected with the main pipe 41, the branch pipe 42 is perpendicular to the main pipe 41, and the branch pipe 42 is perpendicular to the bottom of the detection box 1 ; After the gas is passed into the main pipe 41, it will pass through each branch pipe 42 to the outside.

[0037] Further, the first blocking part 2 is connected to the lower part of the motor casing...

Embodiment 2

[0044] like Figure 11-13 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment is additionally equipped with a place for putting the motor casing into the detection box 1 and / or removing the motor casing from the detection box 1. The material part, specifically: the discharge part 7 includes a fixed frame 70, a first clip 71, a second clip 72 and a first driver 73, the fixed frame 70 is a metal frame, and the second The clip 72 is a metal claw, and the upper part of the second clip 72 is connected with the fixed frame 70. The first clip 71 is also a metal claw, and the first clip 71 is connected to the first drive. 73, wherein the first driving member 73 is a cylinder, and the first driving member 73 is connected to the fixing frame 70, so when the motor casing needs to be fixed, the first driving member 73 drives the The first clamping piece 71 clamps the motor casing; at the same time, the discharging part 7 also includes a second drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com