Refractive index measuring device and measuring method for liquid

A liquid refractive index and measuring device technology, which is applied in the field of measurement, can solve problems such as inaccurate liquid refractive index measurement, and achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

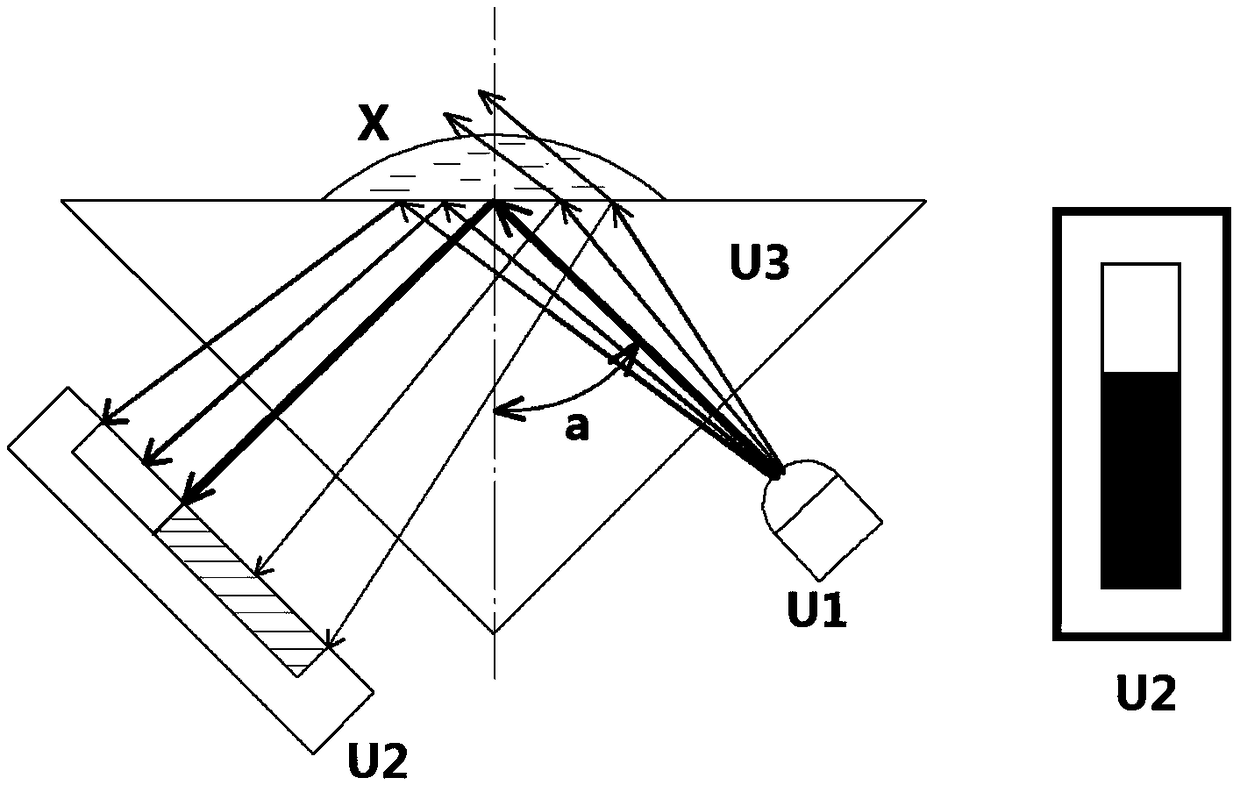

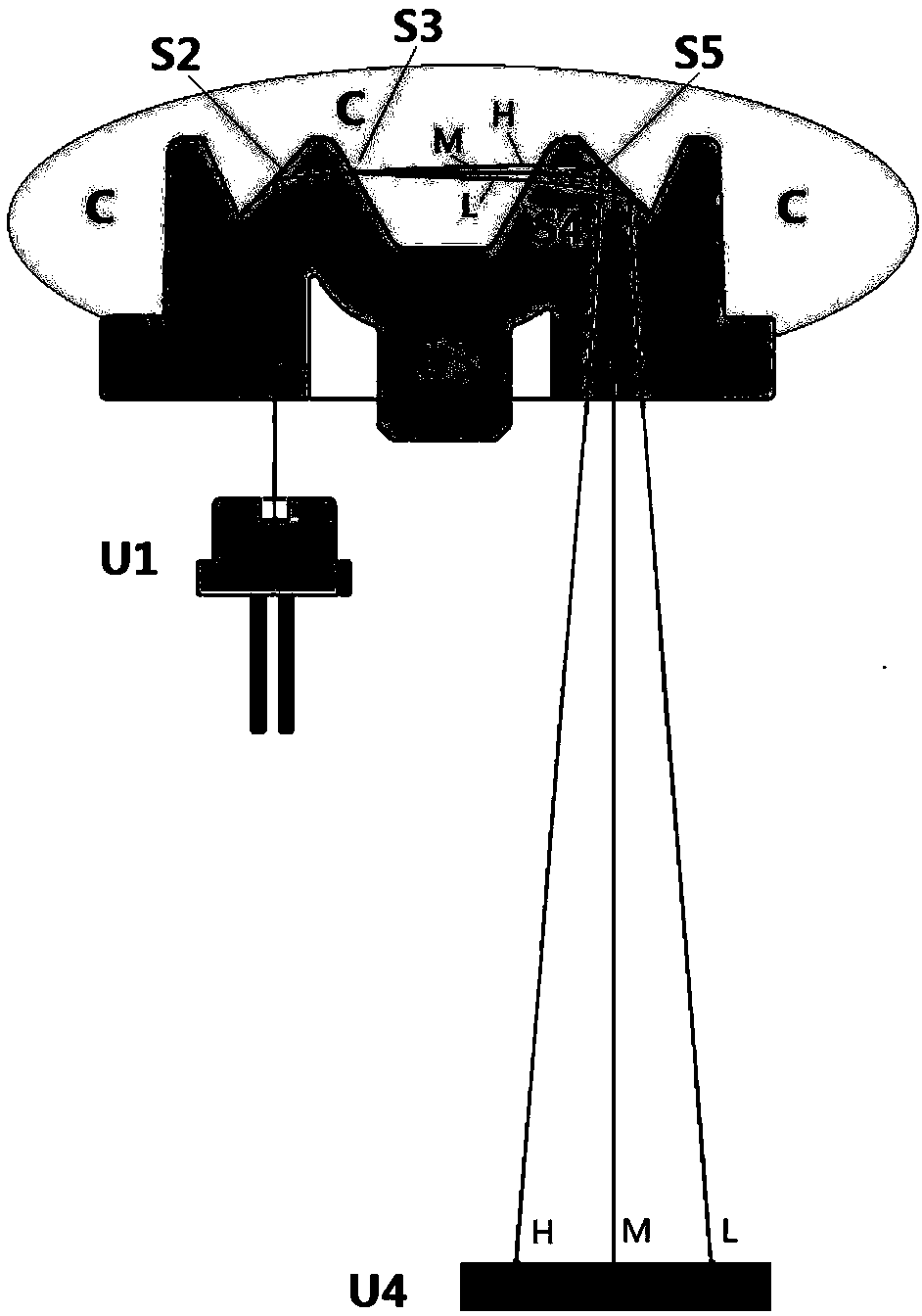

[0050] Such as figure 2 As shown, Embodiment 1 of the present invention provides a liquid refractive index measuring device, comprising:

[0051] The light source U1, preferably a laser light source, is used to limit the incident angle of the incident light beam;

[0052] The optical resin prism U3 includes an incident surface S1, a first reflective surface S2, a first surface S3 in contact with the liquid to be measured, a second surface S4, a second reflective surface S5, and an outgoing surface S6. The light beam emitted by the light source passes through the After combing the collimating lens, a parallel light beam is formed and enters the incident surface S1 of the optical resin prism, and the incident light beam propagates in the optical resin prism and is reflected on the first reflection surface S2 to form a first reflection The light beam propagates in the optical resin prism and reaches the first surface S3 in contact with the liquid to be measured, where transmiss...

Embodiment 2

[0061] Such as image 3 As shown, Embodiment 2 of the present invention provides a liquid refractive index measuring device. On the basis of Embodiment 1, this embodiment further includes:

[0062] The collimating lens U2 is disposed between the light source U1 and the optical resin prism U3, and is used for converging the light beam emitted from the light source U1 to enter the optical resin prism U3. And the main axis of the collimating lens coincides with the center of the light source.

[0063] Further, the collimating lens U2 is composed of two optical surfaces, one optical surface is an aspheric mirror; the other optical surface is a Powell prism (powerwell lens).

Embodiment 3

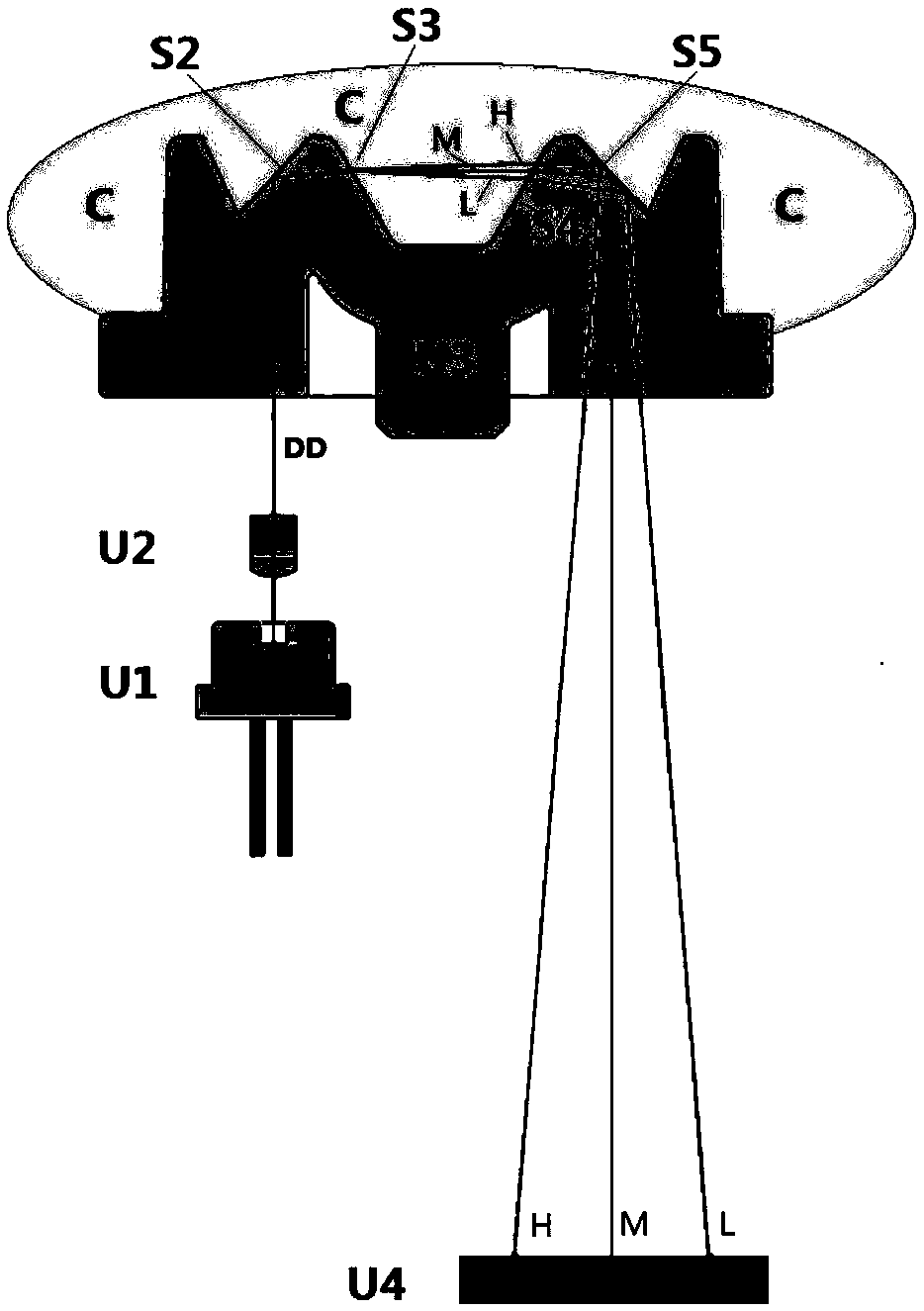

[0065] Such as Figure 4 As shown, Embodiment 3 of the present invention provides a liquid refractive index measurement device. On the basis of Embodiment 2, this embodiment further includes an incident surface S1 and an outgoing surface S6. The incident surface S1 is used to convert the incident light into a linear parallel beam; the exit surface S6 is used to focus the second reflected beam so that when the second reflected beam reaches the receiving plane of the line array image sensor, an approximate point is formed. shaped spot.

[0066] Further, the incident surface S1 is a cylindrical mirror / toric lens.

[0067] Further, the emitting surface S6 is an aspheric mirror / toric lens.

[0068] Preferably, the incident surface S1 and the outgoing surface S6 are integrally formed with the optical resin prism, more preferably, they are made of optical-grade transparent resin material; they are integrally formed by injection molding process, so as to ensure the assembly consiste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com