A fuzzy rough DEMATEL-ANP-based error source diagnosis method for high-end precision bearings in a manufacturing process

A technology of precision bearing and manufacturing process, applied in the field of bearing manufacturing and processing, it can solve the problems of high complexity accumulation and coupling, affecting the fatigue level of workers, difficulty in diagnosing error sources, etc., to achieve the effect of fast programming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] A high-end precision bearing manufacturer needs to diagnose the source of errors in the manufacturing process.

[0062] The implementation steps are as follows:

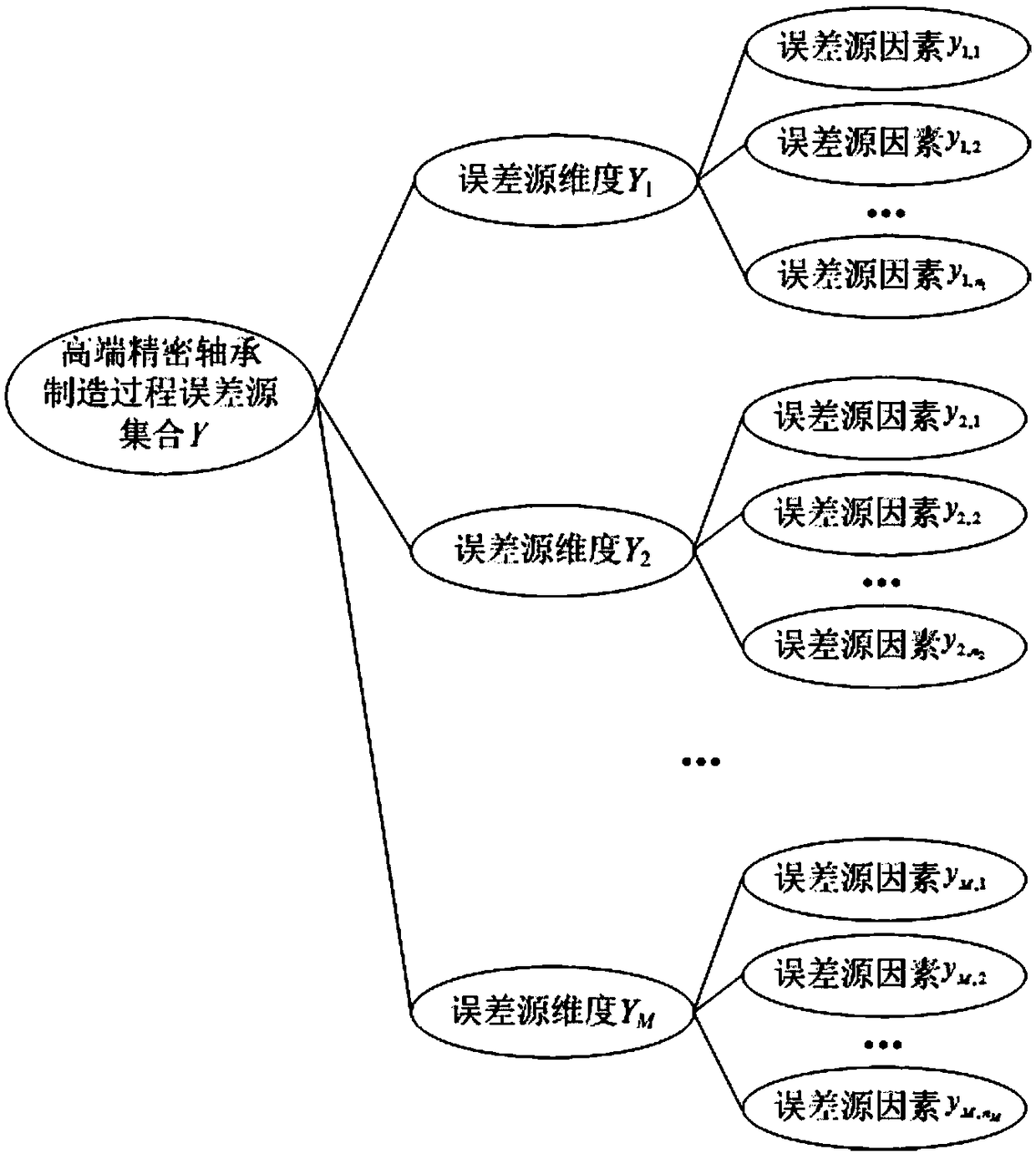

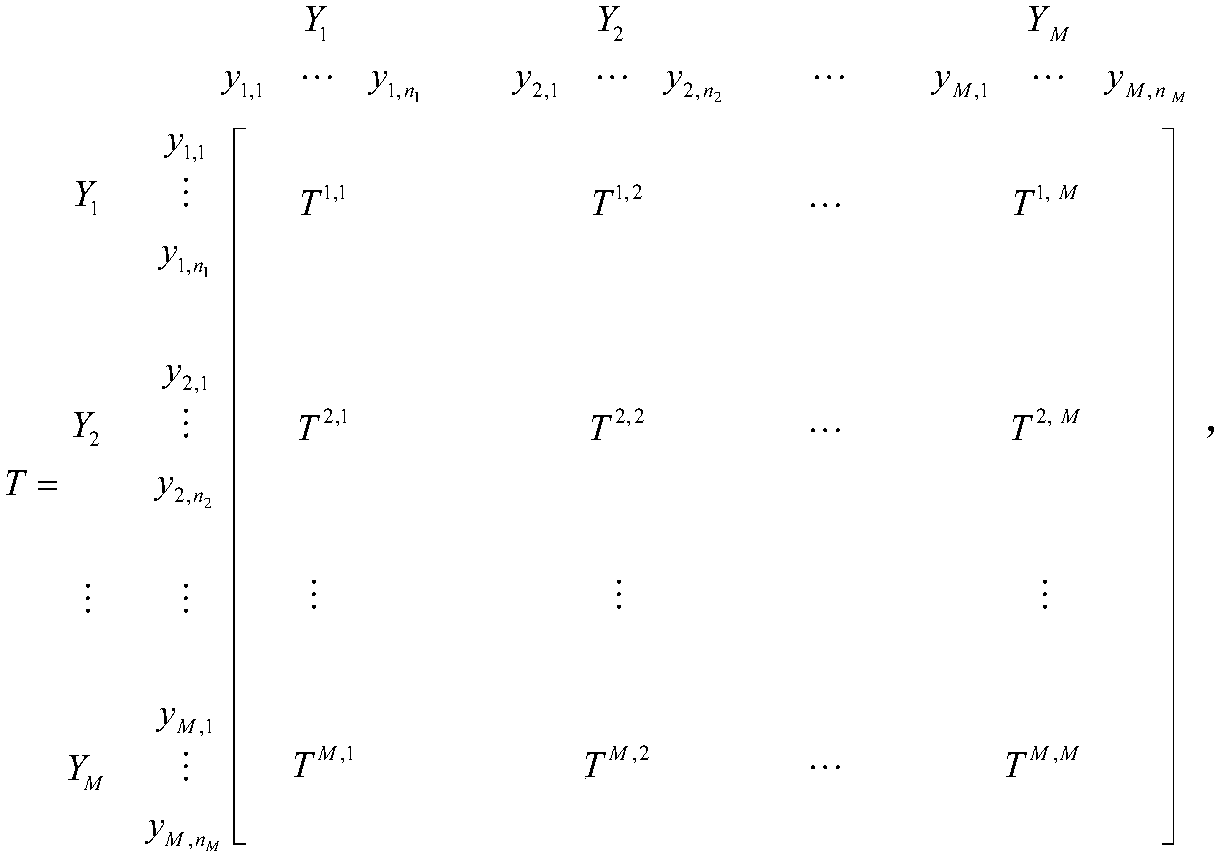

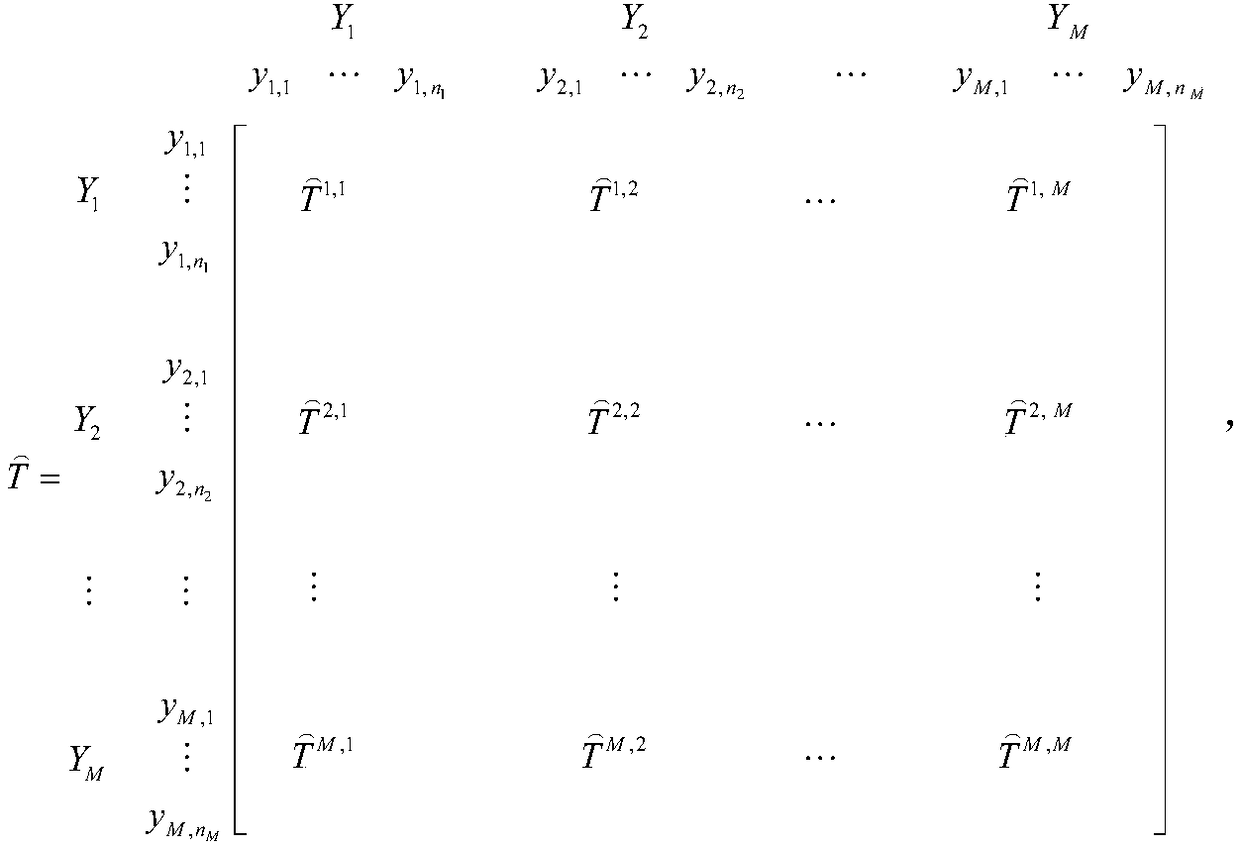

[0063] Step 1: Establish a high-end precision bearing manufacturing process error source set Y, Y contains N error source factors, where N=11;

[0064] Y is further divided into M error source dimensions: Y 1 ,Y 2 ,...,Y M , where M=4;

[0065] Y 1 ,Y 2 ,...,Y M include n 1 ,n 2 ,...,n M error source factors; for the error source dimension Y g ,Have means Y g The error source factors contained in , where g=1,2,..,M; n 1 ,n 2 ,...,n M meet n 1 +n 2 +...+n M = N; where:

[0066] (1)Y 1 Indicates artificial dimensions, including n 1 error source factors: y 1,1 =y 1 = Worker's physiological characteristics, y 1,2 =y 2 = worker's desire for quickness, y 1,3 =y 3 = degree of worker fatigue, y 1,4 =y 4 = worker's fluke mentality, that is, n 1 = 4;

[0067] (2)Y 2 Indicates the device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com