A wafer detecting method

A detection method and wafer technology, which can be used in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., and can solve problems such as deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

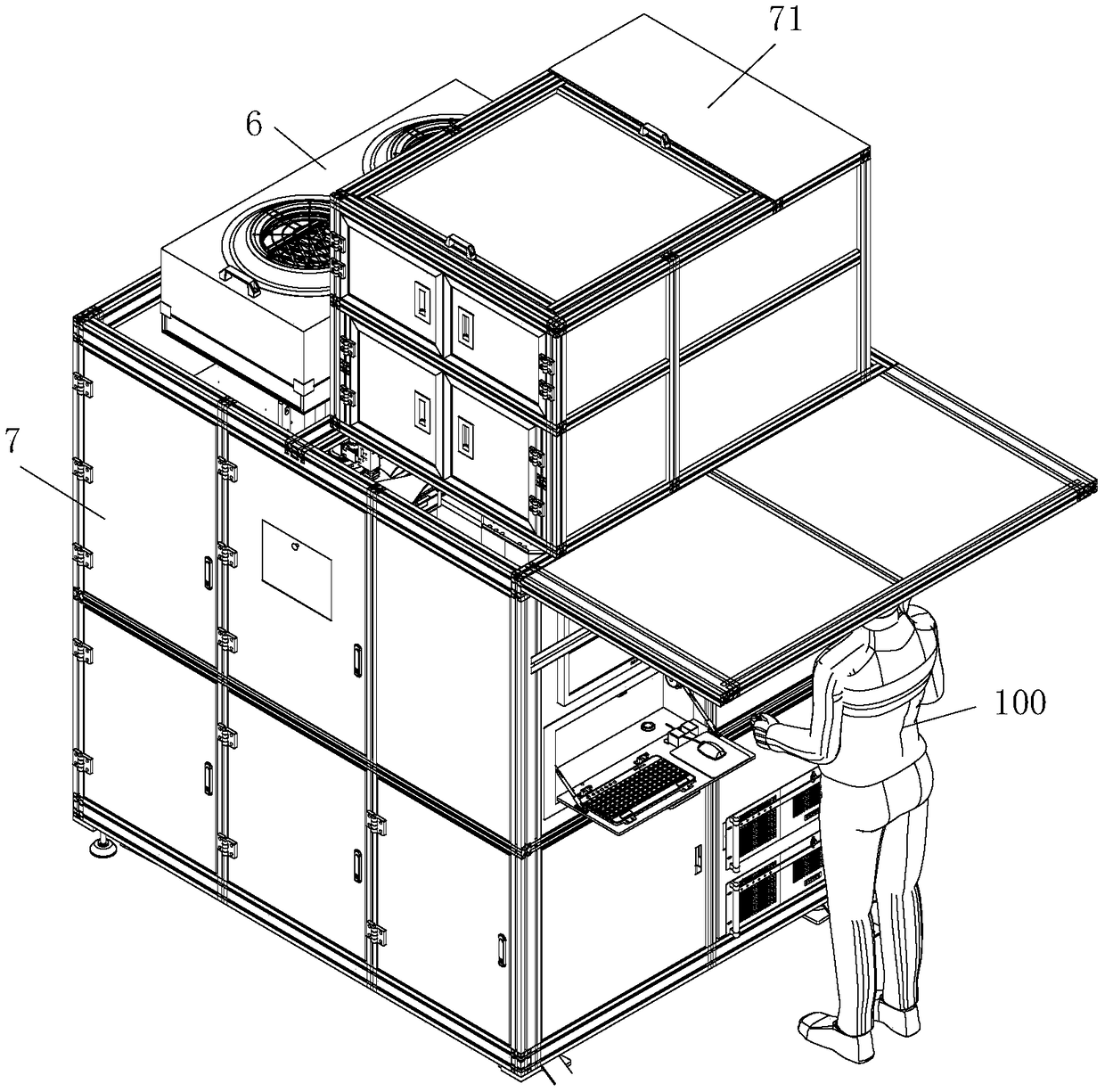

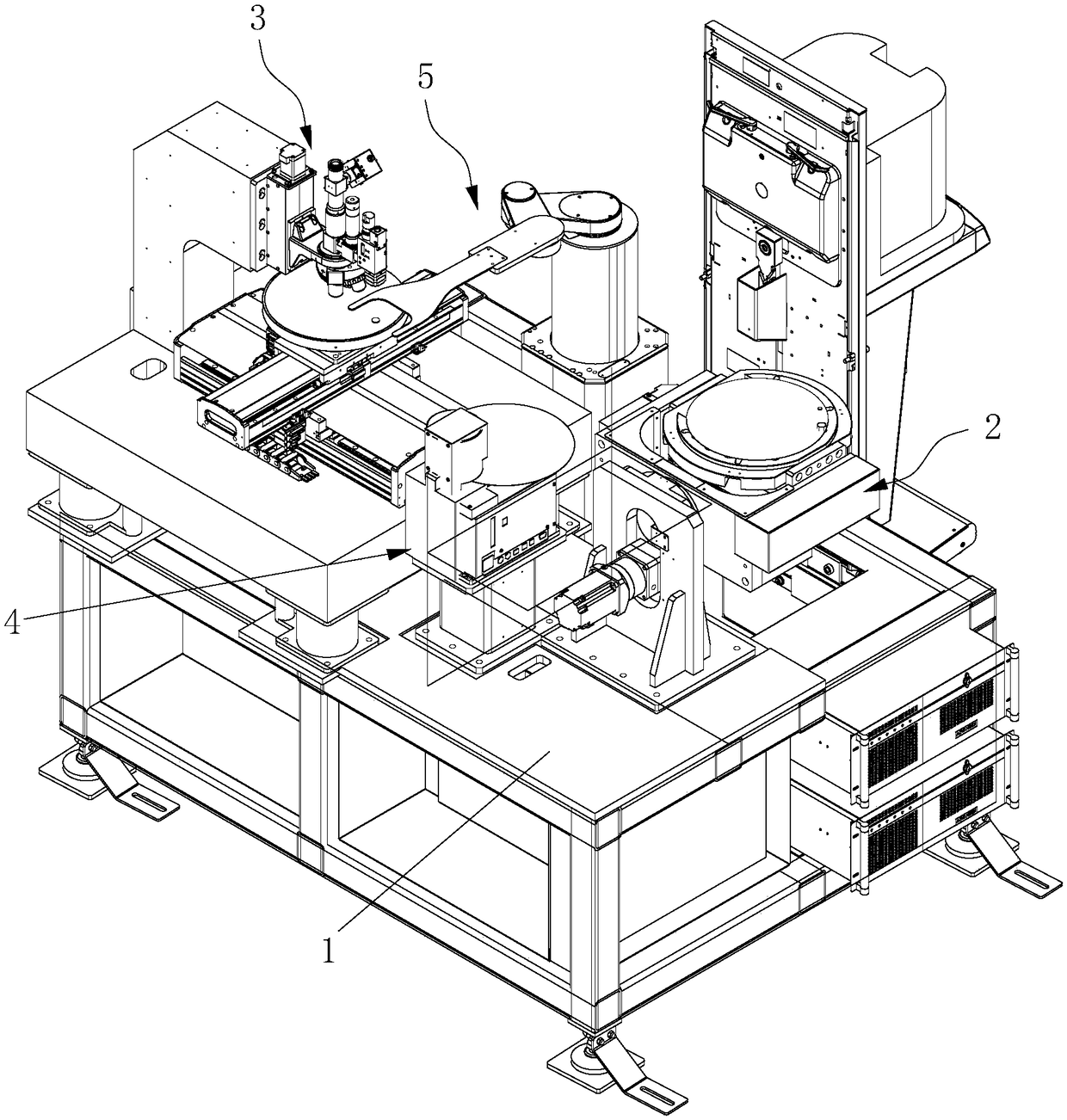

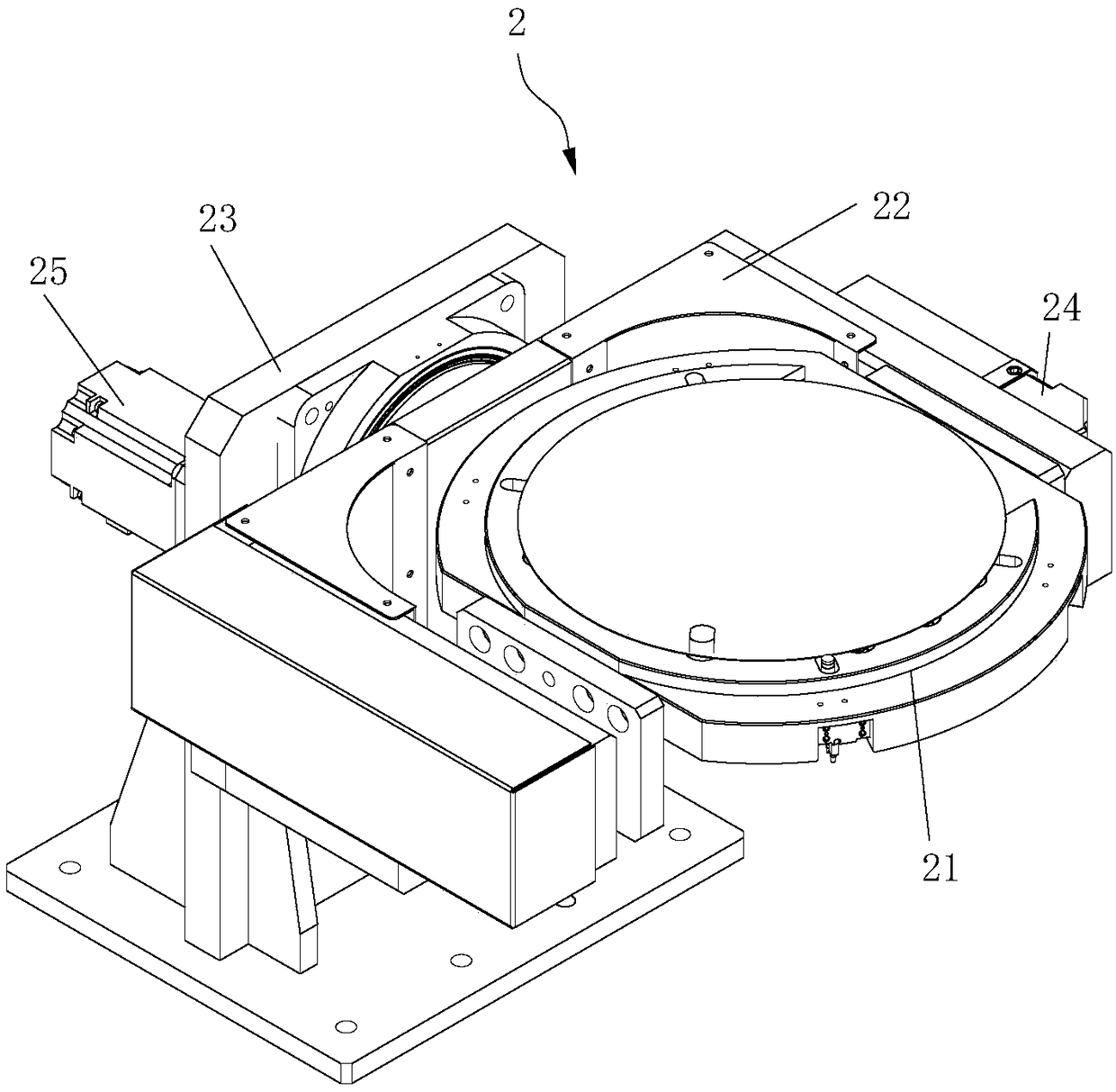

[0040] This embodiment discloses a wafer detection device, such as figure 1 and 2 As shown, the wafer detection equipment includes a working platform 1, on which at least a macroscopic detection station 2 and a microscopic detection station 3 are arranged, and a handling device 5 is also arranged on the working platform 1, and the handling device 5 can The wafer to be inspected is transported to the macro inspection station 2 and the micro inspection station 3. By setting the macro inspection station 2 and the micro inspection station 3 on the wafer inspection equipment, the wafer can be inspected macroscopically and microscopically. Among them, the macro inspection station 2 mainly observes the defects visible to the naked eye on the wafer; the microscopic inspection Station 3 mainly uses the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com