Remote elevator monitoring and inspection

An elevator and remote technology, which is applied to TV, measuring devices, remote control aircraft, etc., can solve problems such as elevator stop running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

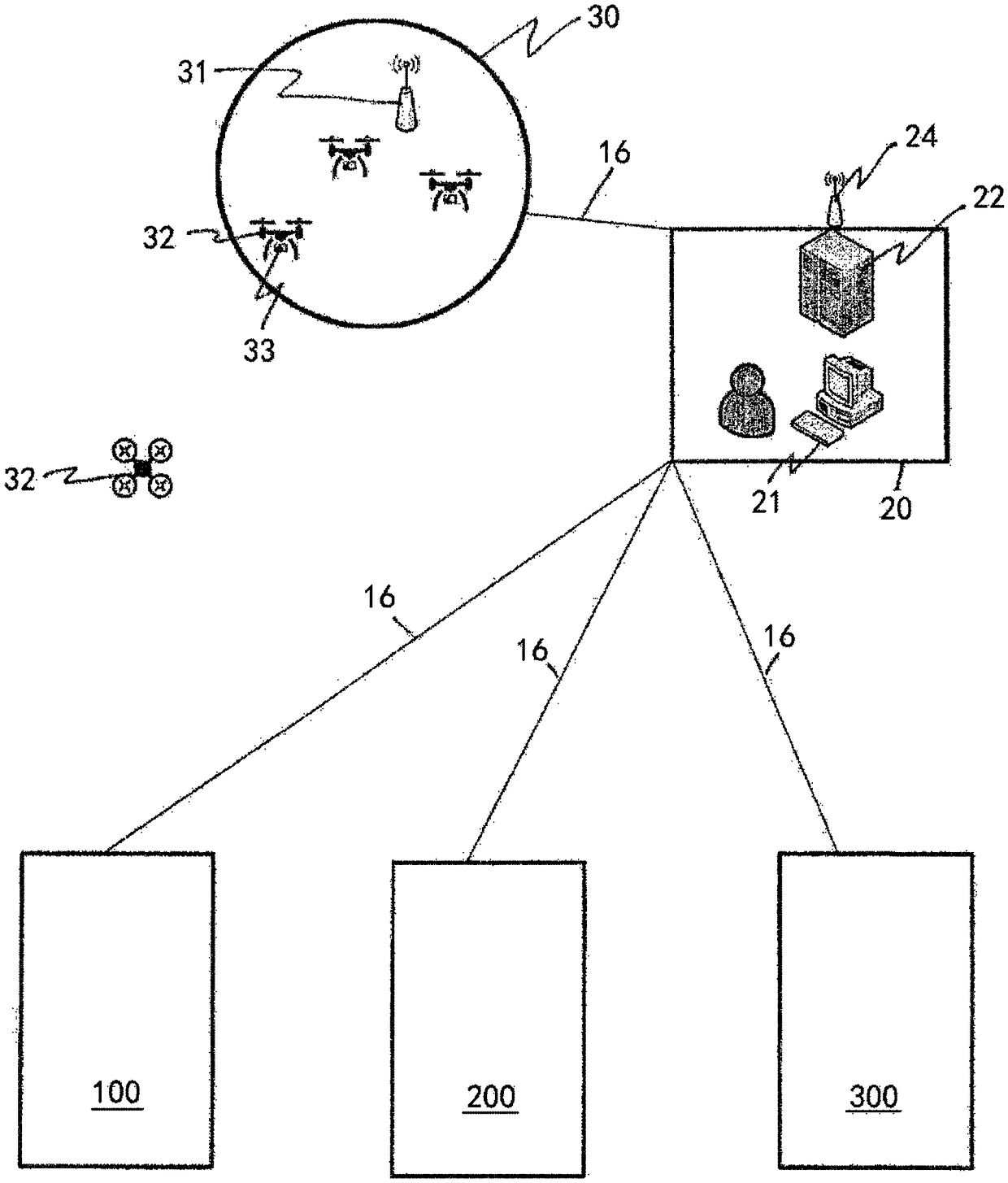

[0024] figure 1 is an exemplary schematic diagram showing an arrangement of a system for remote detection and monitoring of a plurality of elevator installations 100 , 200 and 300 . The system comprises a teleservice center 20 which regulates the operation of the elevator installations and monitors and records the serviceability status of the elevator installations 100 , 200 and 300 . The service center 20 is composed of a computer system 21 and a database 22 in which data related to serviceability status and operation status are stored. The computer system 21 and the database 22 are connected via a data bus. The data stored in the database 22 and / or the actual operating data of the elevator installation 100 can be called up via the data bus by means of an additional data processing device and processed further for additional evaluation. The service center 20 also includes a communication unit 24 enabling the service center 20 to communicate with a controller within each ele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap