Vehicle body structure used for vehicle

A body and vehicle technology, applied to vehicle components, substructure, superstructure, etc., can solve problems such as body column bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

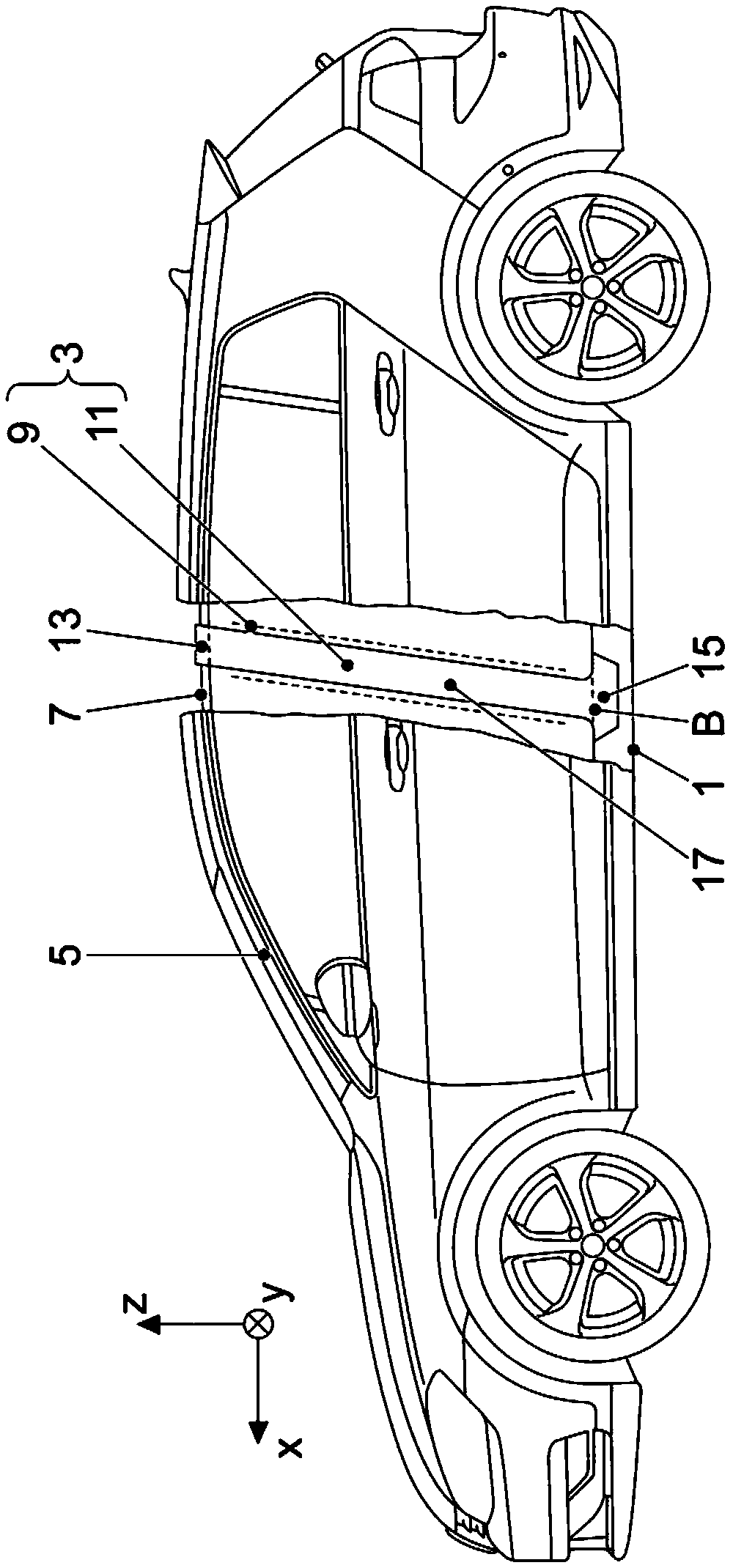

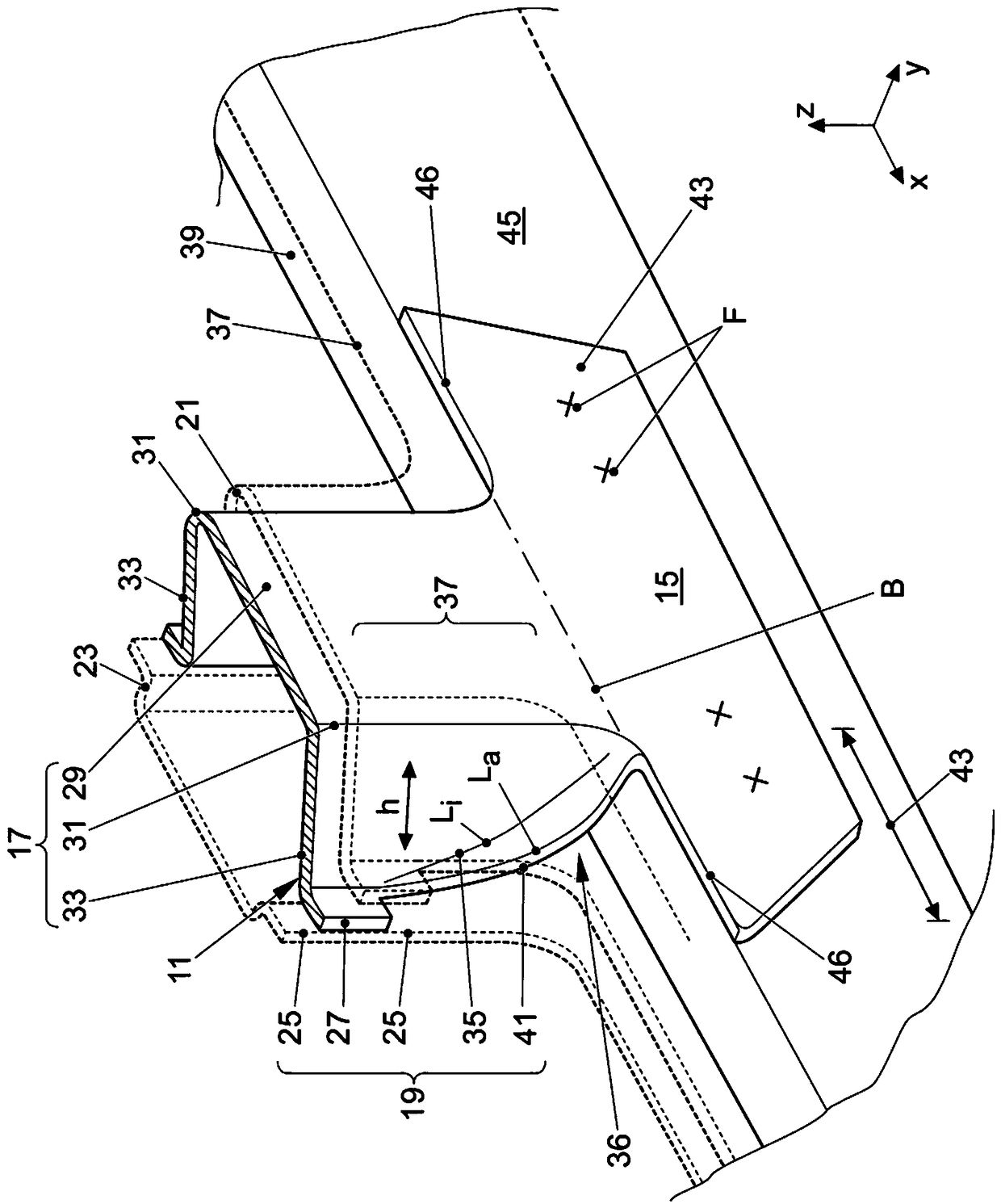

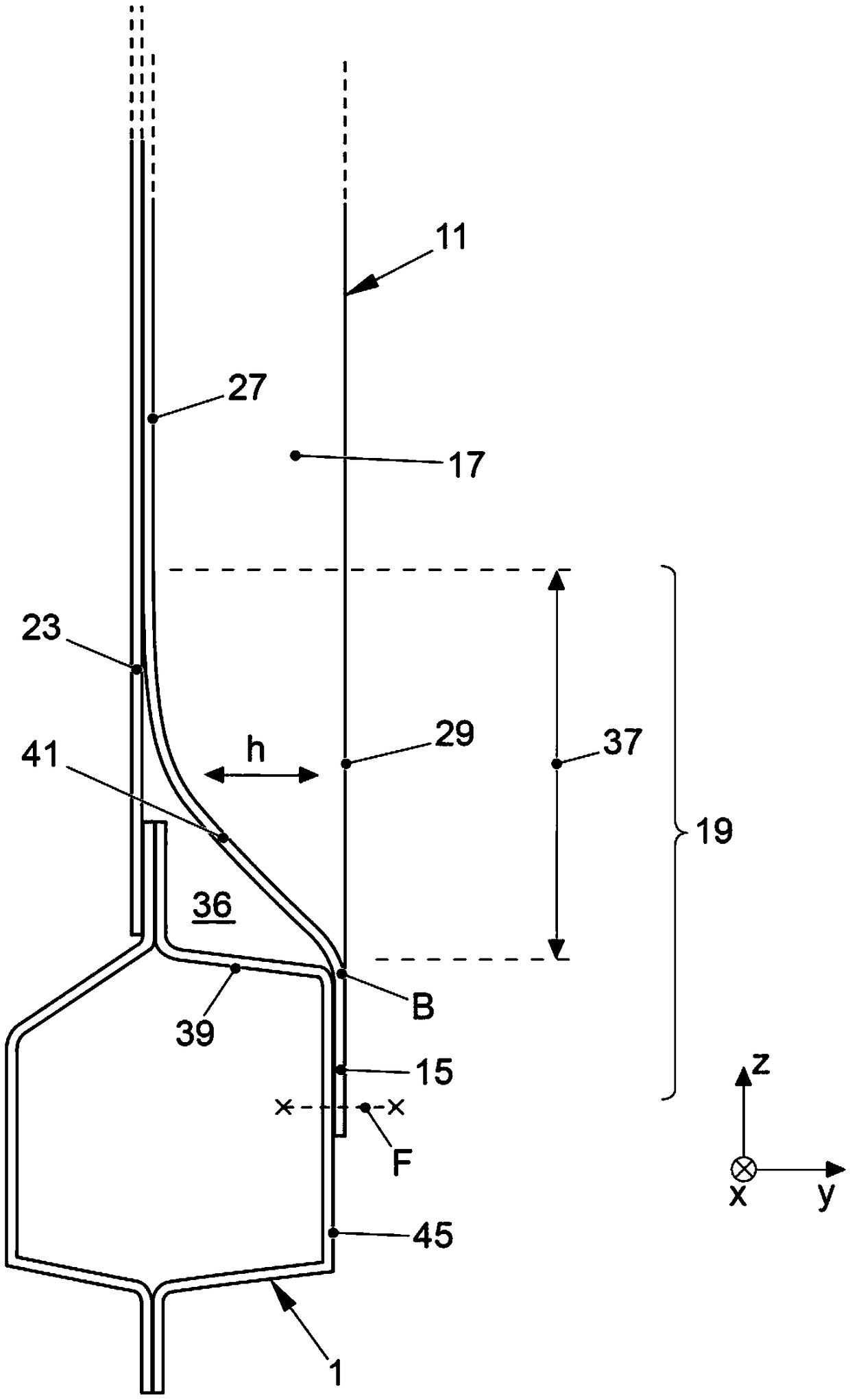

[0021] exist figure 1 A vehicle is shown in , wherein the side wall components of the body-in-shell are highlighted in a partial section in the central vehicle region along the vehicle longitudinal x. The body-in-white has a lower vehicle side member, not shown, which transitions into a lateral door sill 1 in the region of the vehicle passenger compartment. The B-pillar 3 of the side wall assembly is arranged behind the A-pillar 5 in the vehicle longitudinal direction x and connects the lower rocker 1 of the vehicle body with the roof rail 7 of the roof frame in the vehicle height direction z.

[0022] The B-pillar 3 is used, on the one hand, to stiffen the body laterally and, on the other hand, to accommodate components such as seat belt retractors or the like. The B-pillar 3 is here embodied as a hollow beam 9 consisting of shell-like inner and outer panels 23 , 21 , as figure 1 or figure 2 shown. The lateral impact resistance of the B-pillar 3 in the event of a lateral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com