Controllable biodegradable material preparation method

A biodegradable material and starch raw material technology, applied in the field of biodegradable material preparation with controllable degradation rate, can solve the problems that the strength of the composition cannot fully meet the requirements of use, the difficulty of uniform miscibility, and the high energy consumption of the distillation process, etc., to achieve convenience Degradation rate and material mechanical properties, regulation of degradation rate and material mechanical properties, effect of strong penetrating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

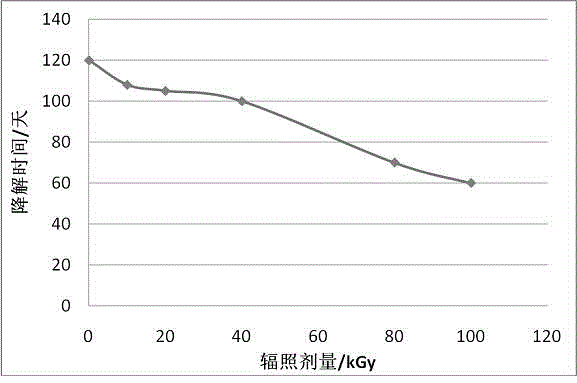

Embodiment 1

[0026] Take 100g of cornstarch, pass through a 40-mesh sieve after drying, the irradiation dose is 3kGy, and the product dosage unevenness is U=1.3; Fatty acid 5g, polylactic acid 30g, sensitizer and accelerator each 1g, fully stirred, and mixed evenly; then the above mixed sample was placed in an aluminum foil bag, vacuum-packed and then irradiated, the dose was 5kGy, and the product dose was not uniform The degree U=1.3; the irradiated miscible material is extruded and granulated to make a special material for full biodegradation. The material is made into a plastic film, and then irradiated with 10kGy, and covered with a film in a vegetable greenhouse, and it will be completely degraded within 170 days.

Embodiment 2

[0028] Take 100g of cassava starch, pass through a 40-mesh sieve after drying, the irradiation dose is 8kGy, and the product dosage unevenness is U=1.25; Fatty acid 8g, polylactic acid 40g, sensitizer and accelerator each 2g, fully stirred, and mixed evenly; then the above mixed sample was placed in an aluminum foil bag, packed with nitrogen and then irradiated, with a dose of 10kGy. Uniformity U=1.2; the irradiated miscible material is extruded and granulated to make a special material for full biodegradation. The material is made into a mulch, and then irradiated with 40kGy, and the film is cultivated in the open air, and it will be completely degraded in 160 days.

Embodiment 3

[0030] Take 100g of sweet potato starch, pass through a 40-mesh sieve after drying, irradiate 10kGy, and the product dosage unevenness is U=1.3; then add 5g of nano-silica (or zinc dioxide) with a particle size of 50nm, 35g of polyvinyl alcohol, Polylactic acid 10g, polylactic acid 60g, sensitizer and accelerator each 5g, fully stirred, and mixed evenly; then the above-mentioned mixed sample was placed in an aluminum foil bag, vacuum-packed and then irradiated, the dose was 15kGy, and the product dose unevenness U=1.2; The irradiated miscible material is extruded and granulated to make a special material for full biodegradation. The material is made into a mulch, and then irradiated with 100kGy, and then covered with a film in the vegetable greenhouse, and it will be completely degraded within 140 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com