Production process of high-nutrition sesame oil

A production process and technology of sesame oil, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of not strong sesame oil fragrance, affecting the effect of seasoning and aroma, and difficult to release sesame phenol, so as to retain the original nutritious components of sesame and improve the seasoning. The effect of enhancing aroma, improving oil yield and oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

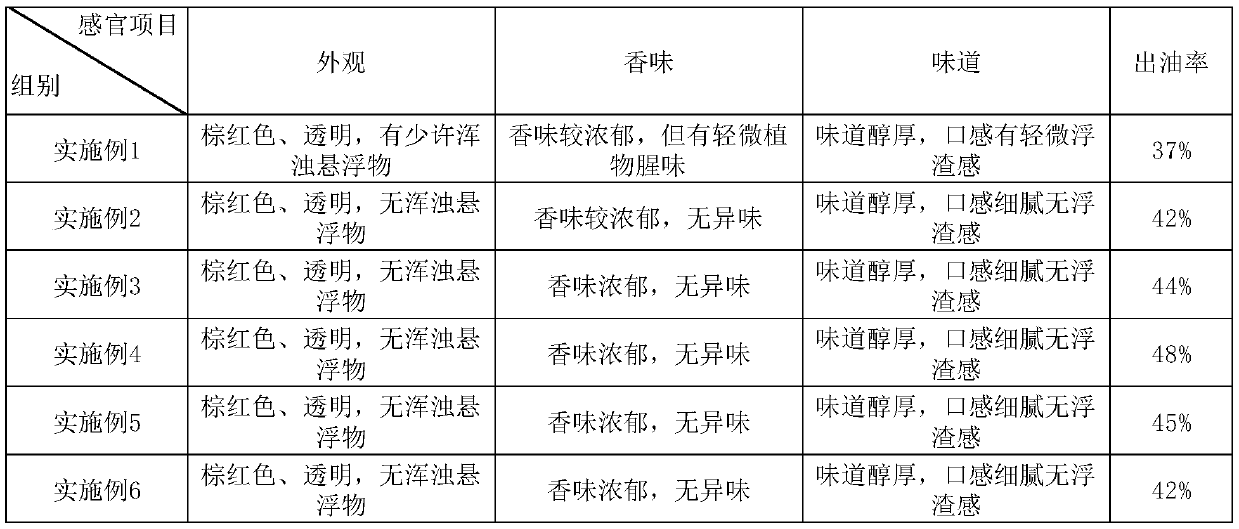

Examples

Embodiment 1

[0042] A production process of high-nutrition sesame oil, comprising the following steps:

[0043] S1. Screening of sesame seeds: take black sesame seeds with uniform color and luster, and remove impurities such as moldy grains, heterochromatic grains, imperfect grains, earth and stones through vibration screening and wind dust removal;

[0044] S2. Rinse: Soak the sesame seeds screened in S1 in water for 1 hour, then stir and rinse twice;

[0045] S3. Stir-fried seeds: Stir-fry the rinsed sesame in S2 at 190°C for 20 minutes at a speed of 40r / min to make the degree of frying reach 70%, then spray cold water on the sesame to cool the sesame, and then stir-fry at 80°C 5min, cooked sesame seeds;

[0046] S4. Raising smoke: put the cooked sesame in S3 in a smoke raising machine to dissipate heat, so as to cool the cooked sesame;

[0047] S5. Blowing: sieve the cooled cooked sesame in S4 and blow air to remove the sesame skin and bran to obtain pure cooked sesame;

[0048] S6. ...

Embodiment 2

[0053] A production process of high-nutrition sesame oil, comprising the following steps:

[0054] S1. Screening of sesame seeds: take black sesame seeds with uniform color and luster, and remove impurities such as moldy grains, heterochromatic grains, imperfect grains, earth and stones through vibration screening and wind dust removal;

[0055] S2. Rinse: Soak the sesame seeds screened in S1 in water for 1.1 hours, then stir and rinse for 3 times;

[0056] S3. Stir-fried seeds: Stir-fry the rinsed sesame in S2 at 192°C for 22 minutes at a speed of 41r / min to make the degree of frying reach 70%, then spray cold water on the sesame to cool the sesame, and then stir-fry at 85°C 6min, cooked sesame seeds;

[0057] S4. Raising smoke: put the cooked sesame in S3 in a smoke raising machine to dissipate heat, so as to cool the cooked sesame;

[0058] S5. Blowing: sieve the cooled cooked sesame in S4 and blow air to remove the sesame skin and bran to obtain pure cooked sesame;

[0...

Embodiment 3

[0064] S1. Screening of sesame seeds: take black sesame seeds with uniform color and luster, and remove impurities such as moldy grains, heterochromatic grains, imperfect grains, earth and stones through vibration screening and wind dust removal;

[0065] S2. Rinse: Soak the sesame seeds screened in S1 in water for 1.2 hours, then stir and rinse twice;

[0066] S3. Stir-fried seeds: Stir-fry the rinsed sesame seeds in S2 at 194°C for 24 minutes at a speed of 42r / min to make the degree of frying reach 70%, then spray cold water on the sesame seeds to cool them rapidly, and then stir-fry at 90°C 7min, cooked sesame seeds;

[0067] S4. Raising smoke: put the cooked sesame in S3 in a smoke raising machine to dissipate heat, so as to cool the cooked sesame;

[0068] S5. Blowing: sieve the cooled cooked sesame in S4 and blow air to remove the sesame skin and bran to obtain pure cooked sesame;

[0069] S6. Grinding seeds: adding sesame lignans to the pure cooked sesame in S5, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com