Ship truss web structure and ship structure

A web and girder technology, applied in the field of ship girder web structure and ship structure, can solve the problems of many stress concentration points in through holes, affecting the strength and safety of girder web structure, and many openings, etc., to achieve Reduce fatigue sources, improve structural fatigue resistance, and reduce the effect of stress concentration points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

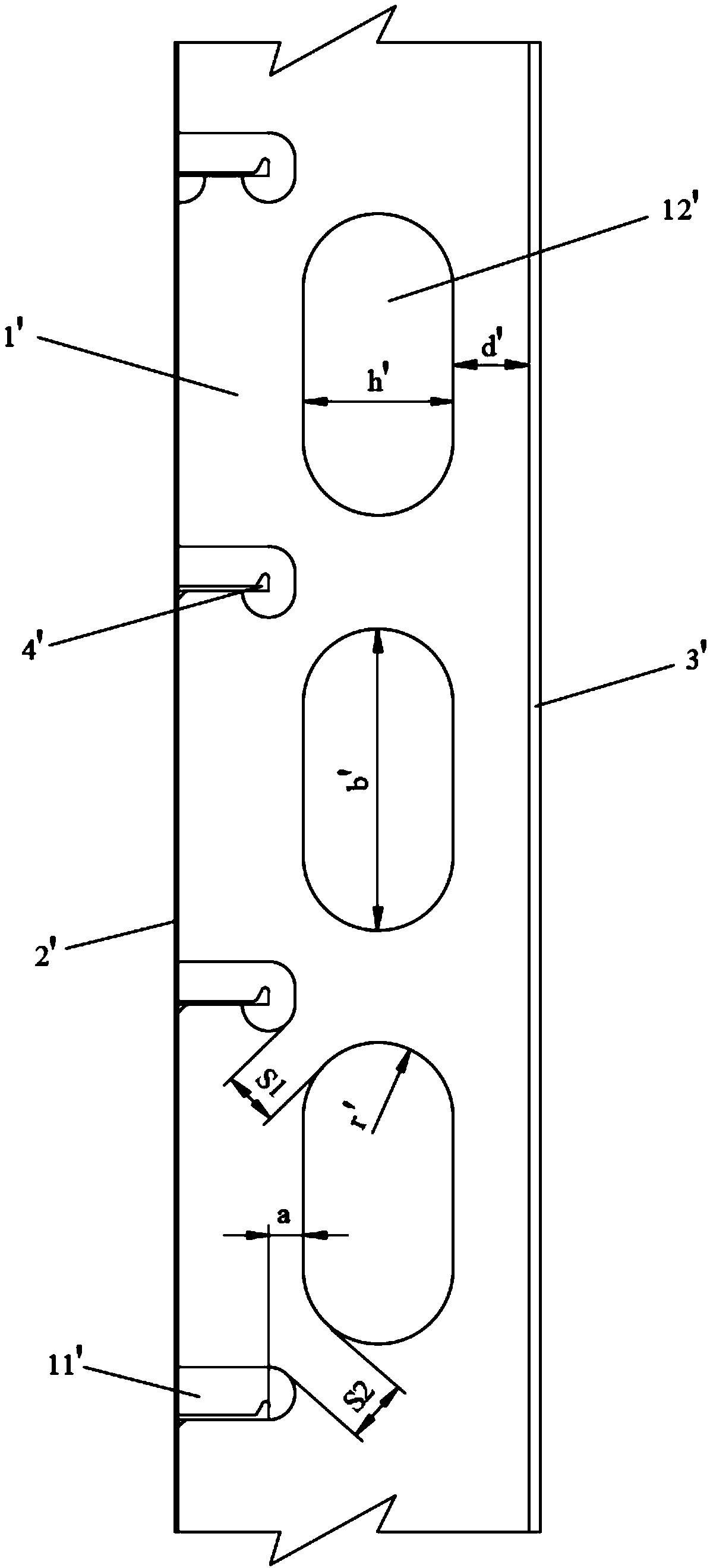

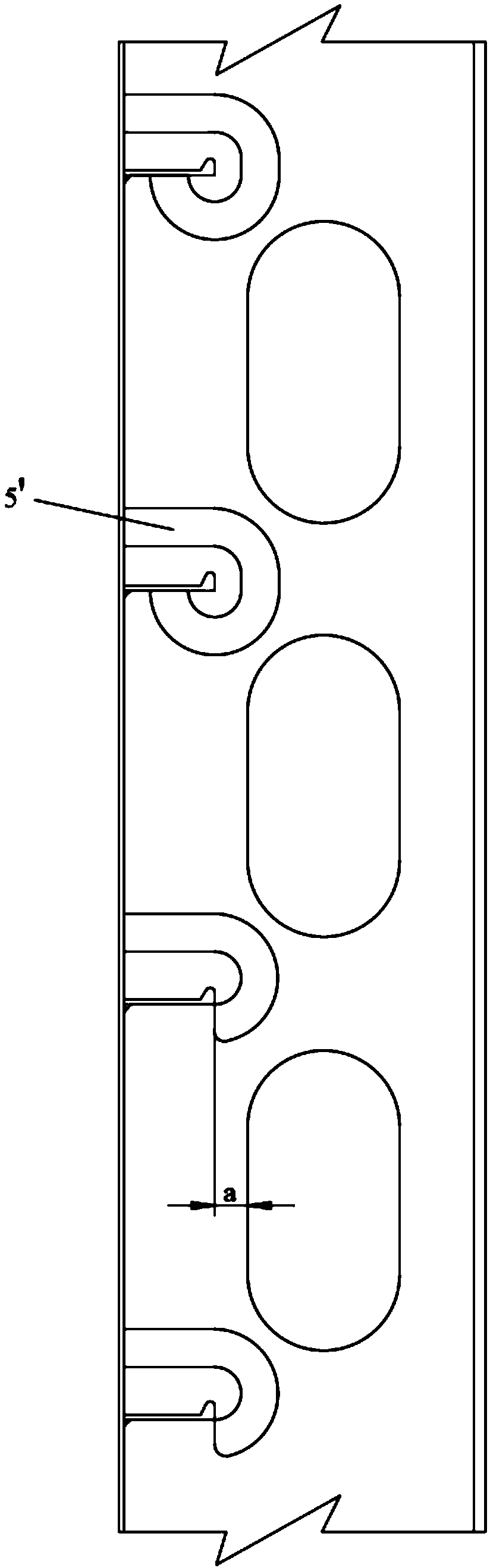

[0027] This embodiment provides a ship girder web structure, which is suitable for ship superstructure structures, especially passenger ships, ro-ro passenger ships and ro-ro ships. The design is adopted at a position above the center of gravity of the ship, which is beneficial to reduce the center of gravity of the empty ship. like image 3 As shown, the ship girder web structure includes a web 1 and a frame 4. One side of the web 1 is connected to the belt plate 2, and the other side is connected to the girder panel 3. A hole 11 , the aggregate 4 is arranged perpendicular to the web 1 through the through hole 11 , one end of the aggregate 4 is in contact with the belt plate 2 , and one side of the aggregate 4 is in contact with the inner wall of the through hole 11 . The ship girder web structure of this embodiment makes the lightening hole or outfitting hole and the through hole share the same through hole 11, which can make the total opening without affecting the strength ...

Embodiment 2

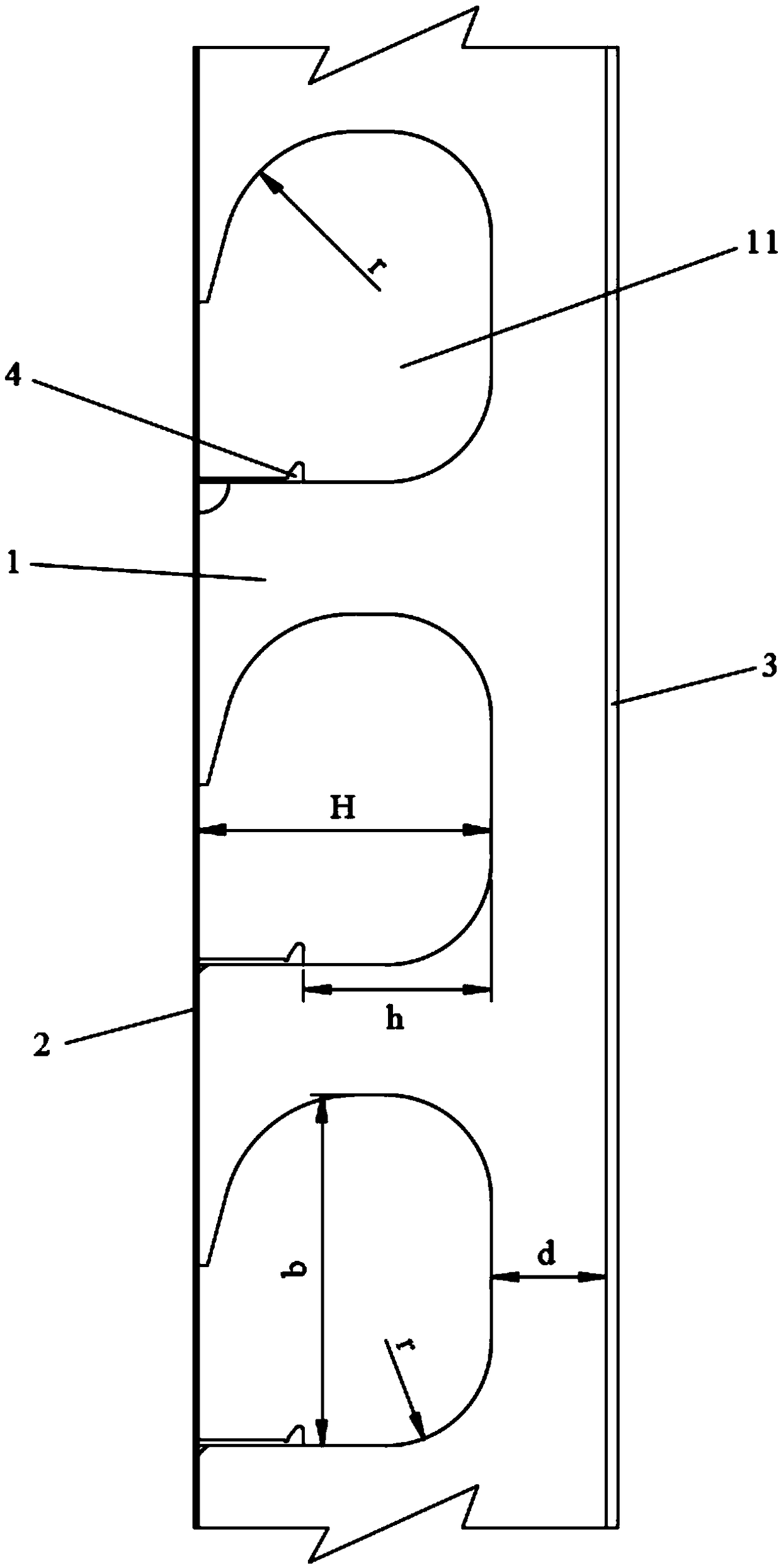

[0031] The difference from Embodiment 1 is that, as Figure 4 As shown, one side of the through hole 11 starts from the intersection of the belt plate 2 and the aggregate 4, fits the aggregate 4 and opens along the width direction of the web 1, and returns to the aggregate 4 after passing through several straight lines and arcs. , and then return to the belt plate 2 along the aggregate 4. This structure makes the shape of the hole where the frame 4 passes fits with the structure of the frame 4, and the connection is more stable, and without increasing the stress concentration point, the area of some openings is appropriately reduced, and the web of the girder is improved. The strength of the plate structure is increased, but at the same time the weight reduction effect is slightly reduced.

[0032] The present invention also provides a ship structure, including the ship girder web structure provided in Embodiment 1 or Embodiment 2.

[0033]The total opening area of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com