Crystallization method for improving bottom crystal flowers of polycrystalline silicon ingot

A polycrystalline ingot and polycrystalline silicon technology, which is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems that affect the conversion efficiency of cells, and the size and uniformity of crystal flowers at the bottom of the ingot are difficult to guarantee. The crystal flower is small and uniform, reducing the high dislocation density and improving the conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

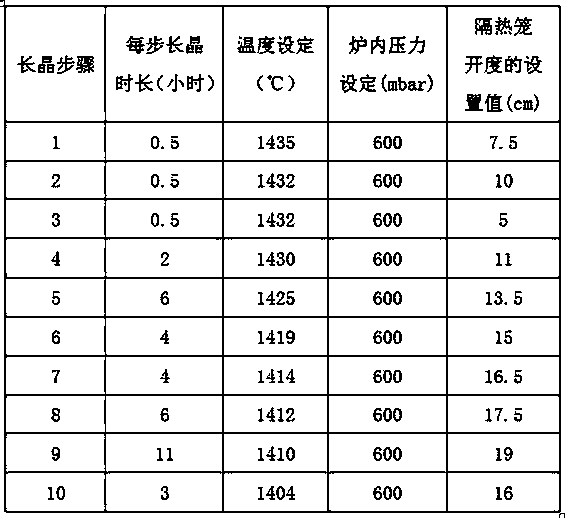

[0014] The crystallization method for improving crystal flowers at the bottom of a polysilicon ingot according to the present invention will be described in detail below with a specific example.

[0015] The first step of the crystallization method for improving the crystal flower at the bottom of the polysilicon ingot of the present invention: raw material smelting: put 850Kg of polysilicon ingot raw material into the crucible of the polysilicon ingot furnace, close the furnace body, and start the polysilicon ingot furnace Start to heat up and vacuumize the furnace at the same time. When the temperature rises to 800°C, argon gas is introduced into the furnace to protect the pressure in the furnace to 600mbar. Continue to raise the temperature to 1560°C until the silicon material is completely melted, and then within half an hour Cool down to 1480°C at a uniform speed, and then cool down to 1430°C at a uniform speed within half an hour to prepare for crystal growth.

[0016] T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap