Supersonic hybrid enhanced structure with frequency characteristics and rocket-based combined engine

A frequency characteristic and enhanced structure technology, applied in the field of supersonic flow mixing control, can solve the problems of thick partitions, difficult to change the rear edge structure, unfavorable heat protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the implementation of the present invention, further description will be made below in conjunction with specific examples.

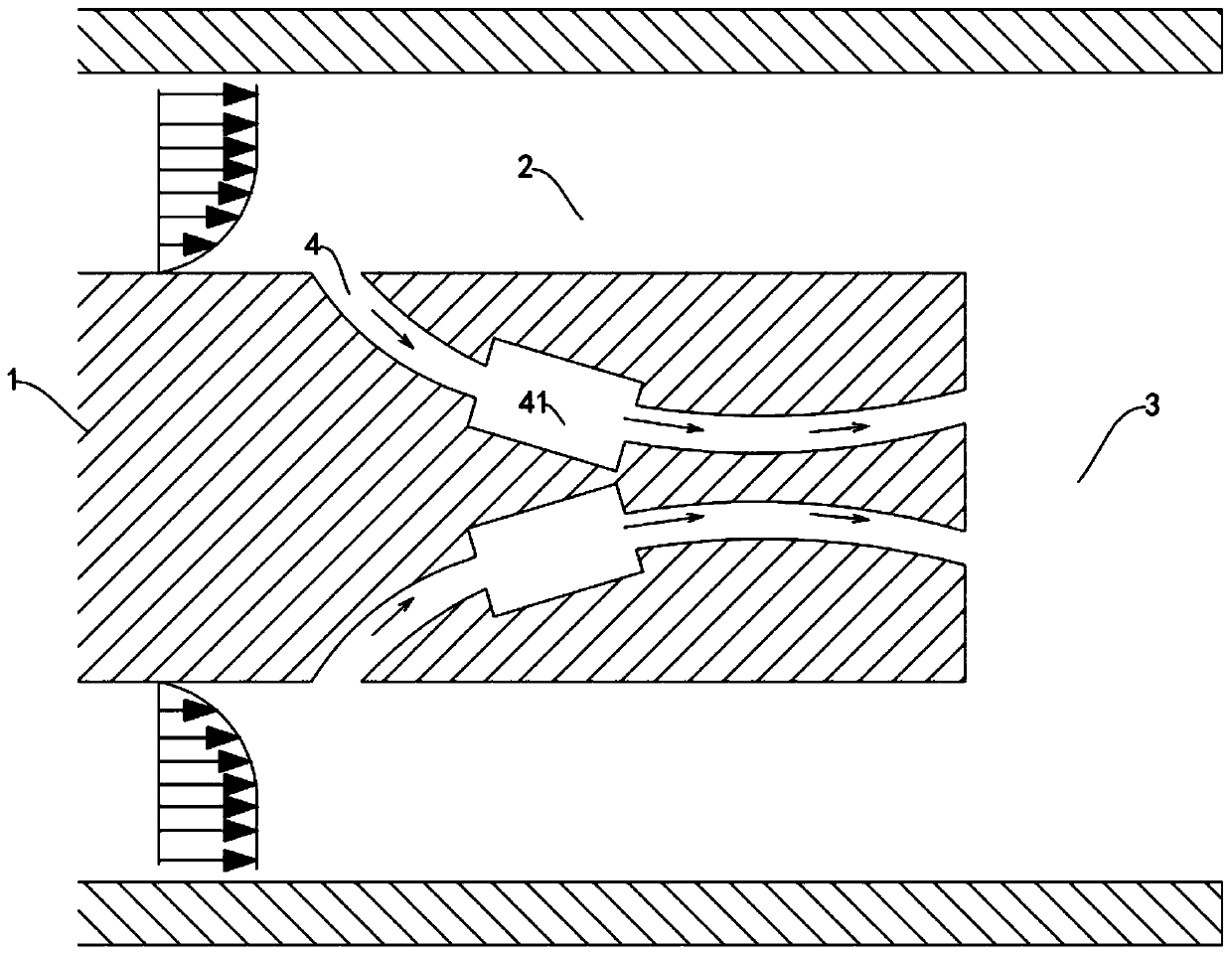

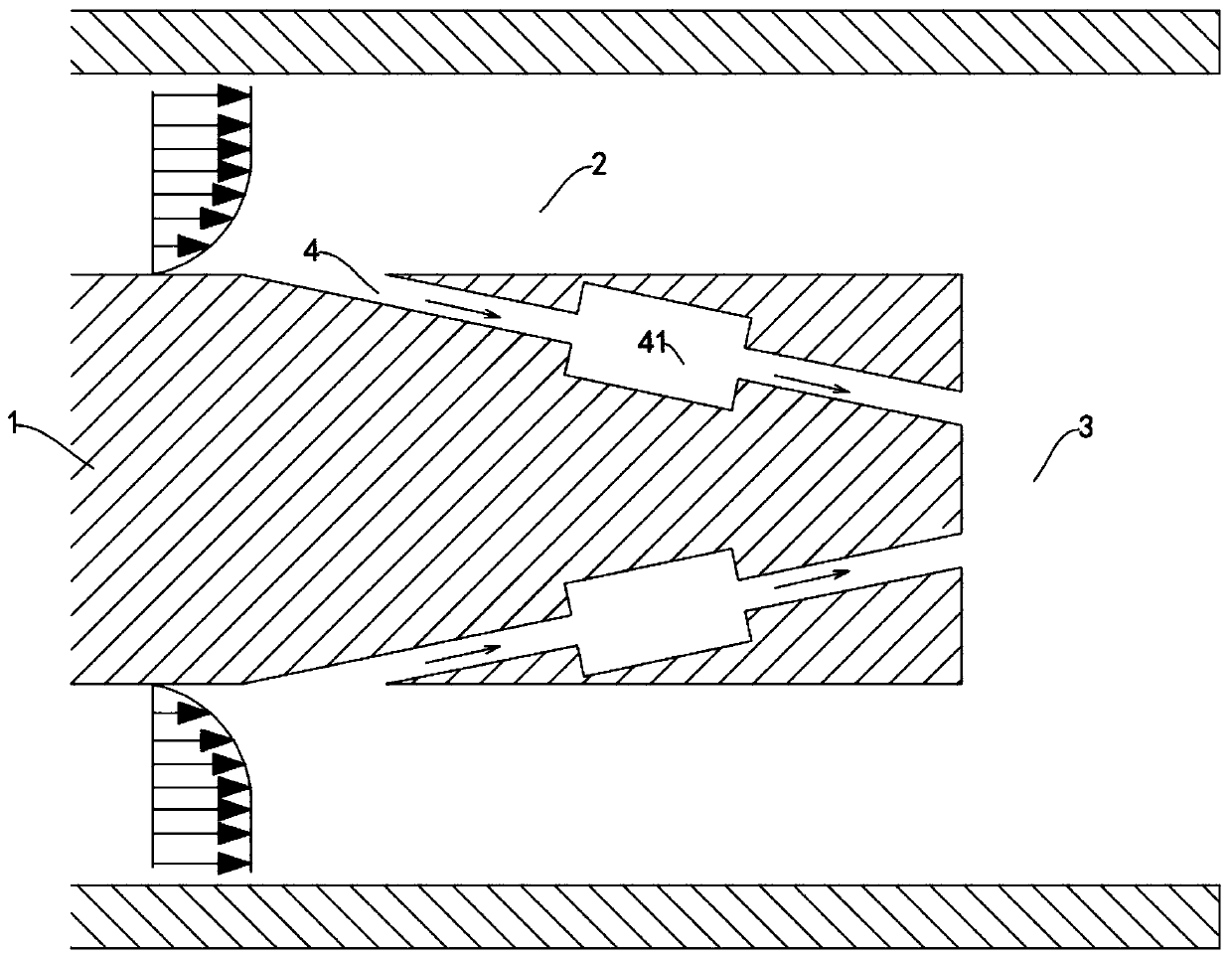

[0025] Such as figure 2 The shown supersonic mixing enhanced structure with frequency characteristics includes a supersonic incoming flow partition 1, and the two sides of the supersonic incoming flow partition 1 are respectively provided with a supersonic incoming flow channel 2, and two supersonic incoming flow channels 2 are connected between the supersonic incoming flow The tail end of the partition 1 is connected and forms a supersonic incoming flow mixing zone 3 behind the tail end of the supersonic incoming flow partition, wherein, the tail end of the supersonic incoming flow partition 1 refers to the direction of the supersonic incoming flow on the supersonic incoming flow partition 1 At the end of the flow direction, the supersonic incoming flow mixing zone 3 communicates with at least one supersonic incoming flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com