Air inlet structure for dual-fuel engine

A dual-fuel engine, intake structure technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of low natural gas replacement rate, short life of injection valves, waste of mixture, etc., and achieves compact structure and transformation. Small, improved combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

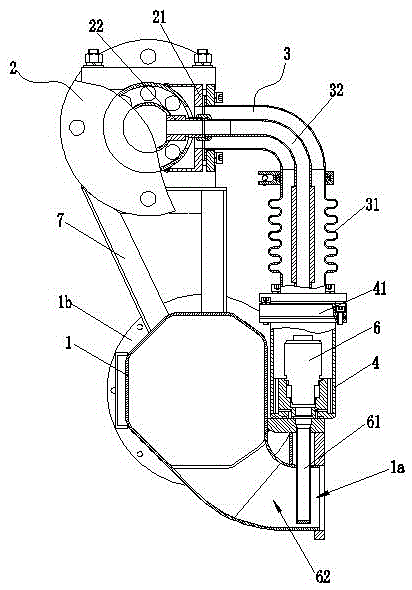

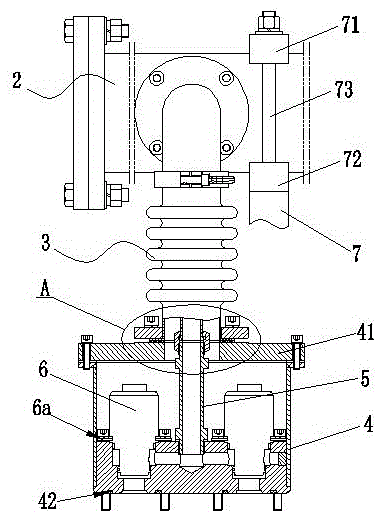

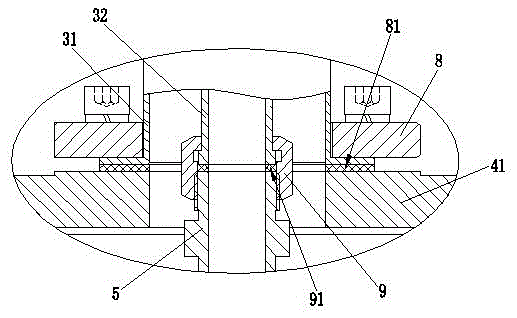

[0024] Such as Figure 1 to Figure 4 The example shown,

[0025] Explanation of icon numbers: air inlet pipe 1, air outlet 1a, inlet flange 1b, fuel inlet main pipe 2, outer air inlet main pipe 21, inner air inlet main pipe 22, fuel inlet branch pipe 3, outer air inlet branch pipe 31, inner inlet Gas branch pipe 32, valve box 4, cover plate 41, valve box bottom sealing ring 42, gas intake pipe 5, gas injection valve 6, gas injection valve fixing plate 6a, nozzle 61, injection hole 61a, partition plate 62, Support 7, upper pressing plate 71, lower pressing plate 72, stud 73, connecting flange 8, flange gasket 81, connecting nut 9, sealing washer 91.

[0026] Such as Figure 1 to Figure 4 as shown,

[0027] The intake structure of a dual-fuel engine of the present invention includes an air intake pipe 1 and a fuel intake main pipe 2, the fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com