Axial series ultra whole-revolution swing hydraulic motors

A technology of oscillating hydraulic motor and oscillating motor, applied in the direction of fluid pressure actuating device, etc., can solve the problem of reducing the performance of servo control, and achieve the effect of simple oil distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

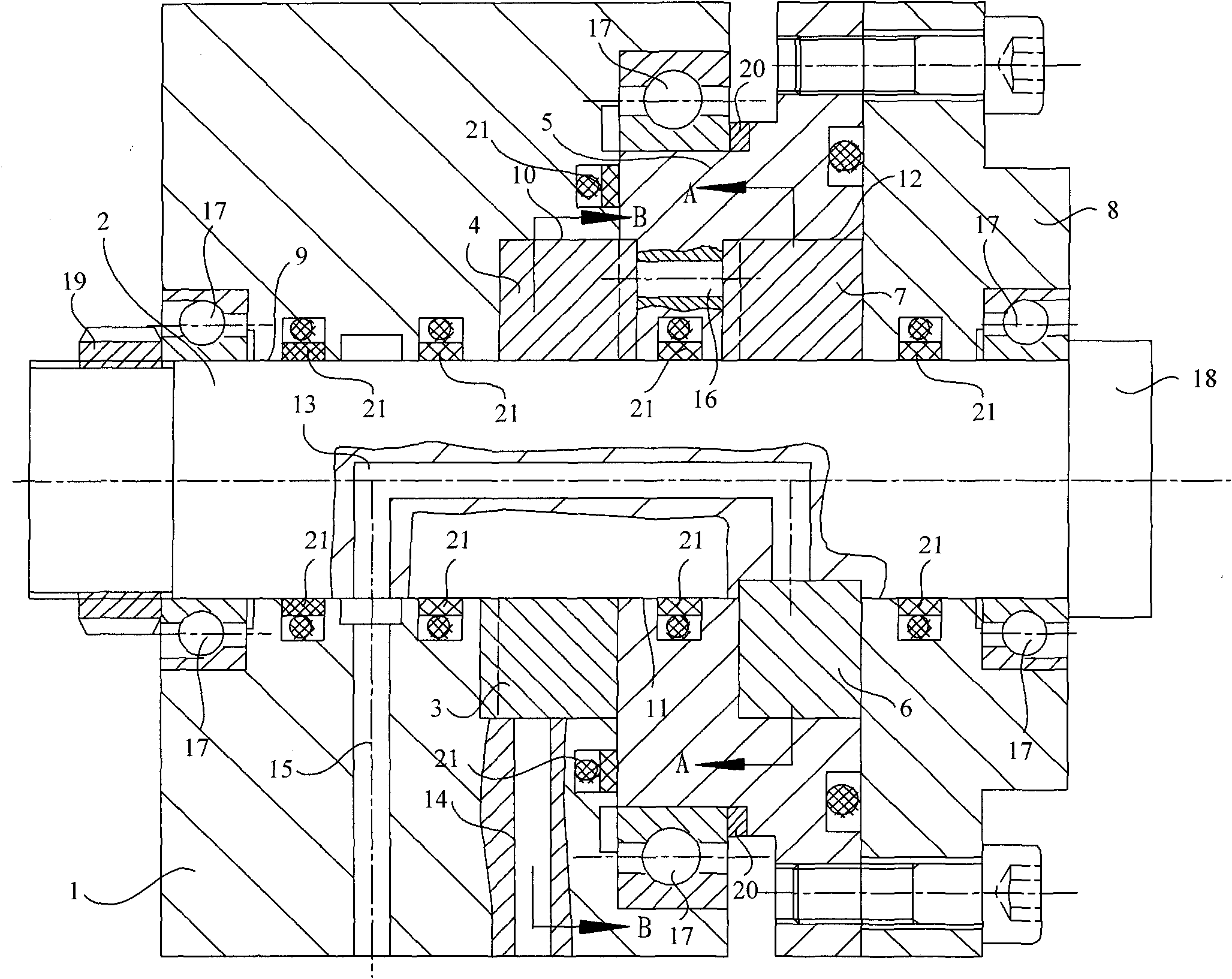

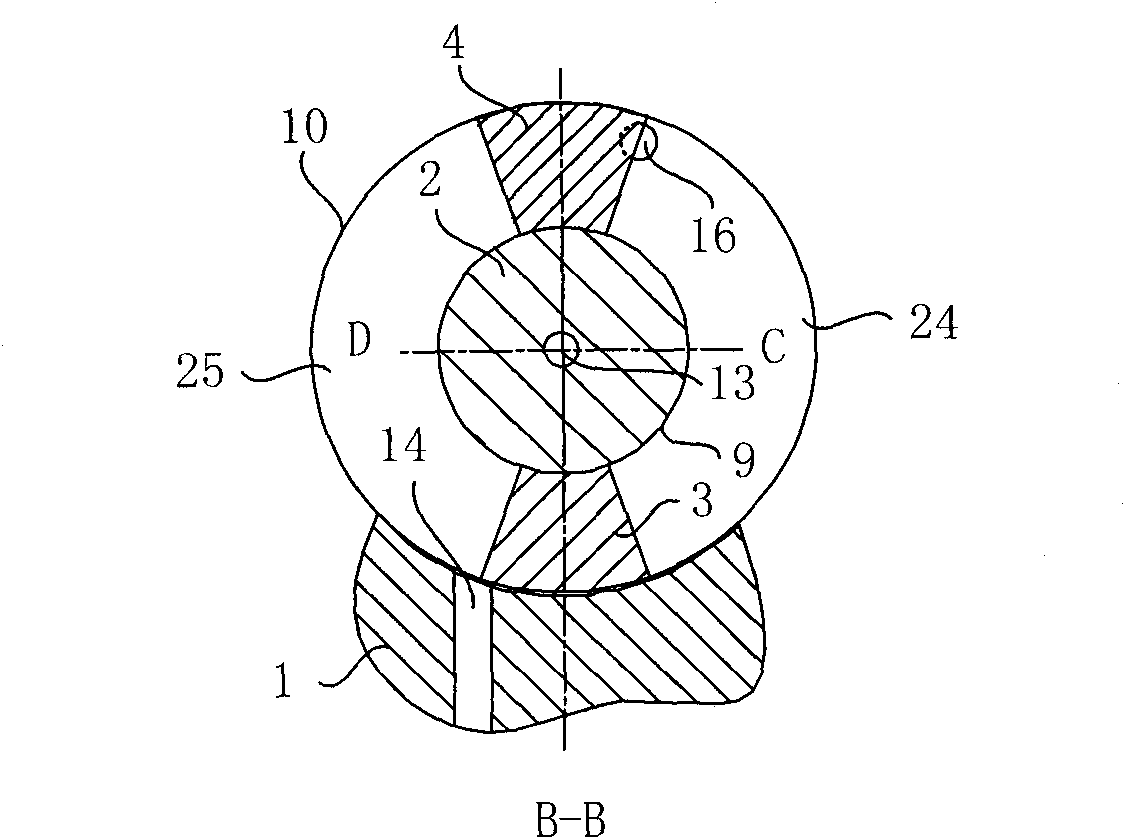

[0025] The axial tandem super full circle swing hydraulic motor of the present invention, such as figure 1 As shown, it includes primary stator 1 , primary stationary blade 3 , primary moving blade 4 , secondary stator 5 , secondary stationary blade 7 , secondary moving blade 6 , rotating shaft 2 and cover plate 8 .

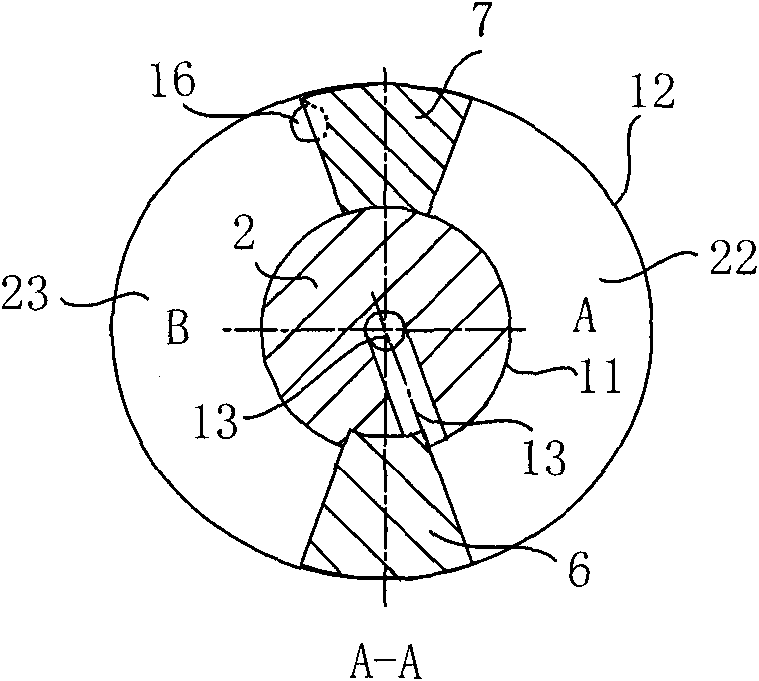

[0026] The secondary stator 5, the secondary stator blades 7, the secondary moving blades 6, the rotating shaft 2 and the cover plate 8 constitute a secondary swing motor, such as figure 1 , figure 2 As shown, the cross-section of the secondary moving blade 6 and the secondary stationary blade 7 is a part of a circular ring, the middle of the secondary stator 5 is provided with a through hole C11 and a non-through hole D12, and the rotating shaft 2 is installed on the side of the secondary stator 5. In the hole C11 , the secondary rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com