Rapid dehumidifying method without dismounting product

A fast and high-quality technology, applied in the direction of drying solid materials, dryers, lighting and heating equipment, etc., can solve problems such as difficult products, moisture discharge, affecting equipment development cycle, cost, etc., to achieve low cost, fast dehumidification, The effect of high dehumidification work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical solutions and advantages in the embodiments of the present application clearer, the exemplary embodiments of the present application will be further described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present application, and Not an exhaustive list of all embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0012] The core idea of this solution is to use the principle of air flow from high pressure to low pressure at the same height, and dehumidify the interior of the product through a high temperature and low pressure environment without dismantling the product, thereby shortening the dehumidification time and reducing maintenance costs.

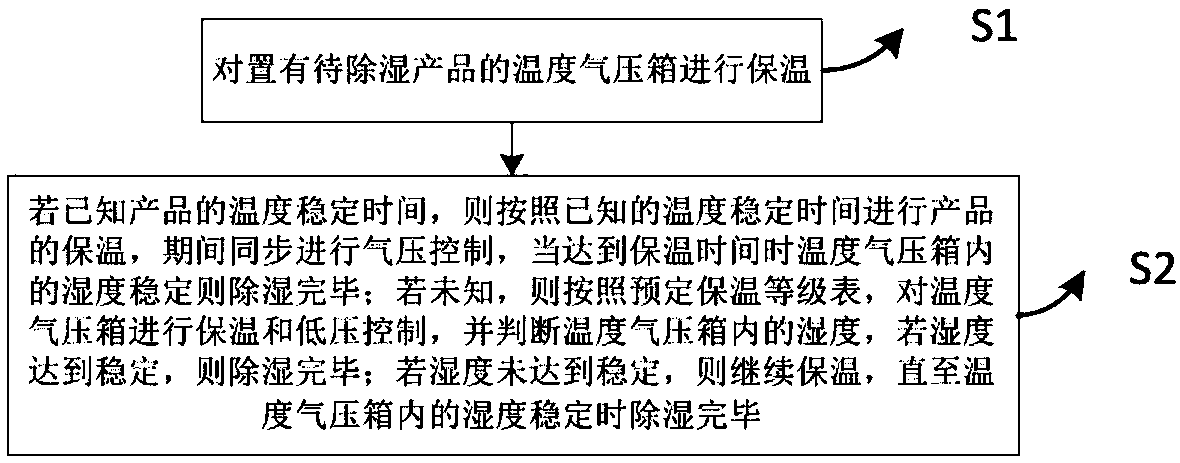

[0013] Such as figure 1 As shown, this solution discloses a quick dehumidif...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap