Automatic spraying device with stirring function

An automatic spraying and functional technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of low efficiency, inhalation of mist paint workers into the body, and many uncertain factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention is capable of various changes in different embodiments without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

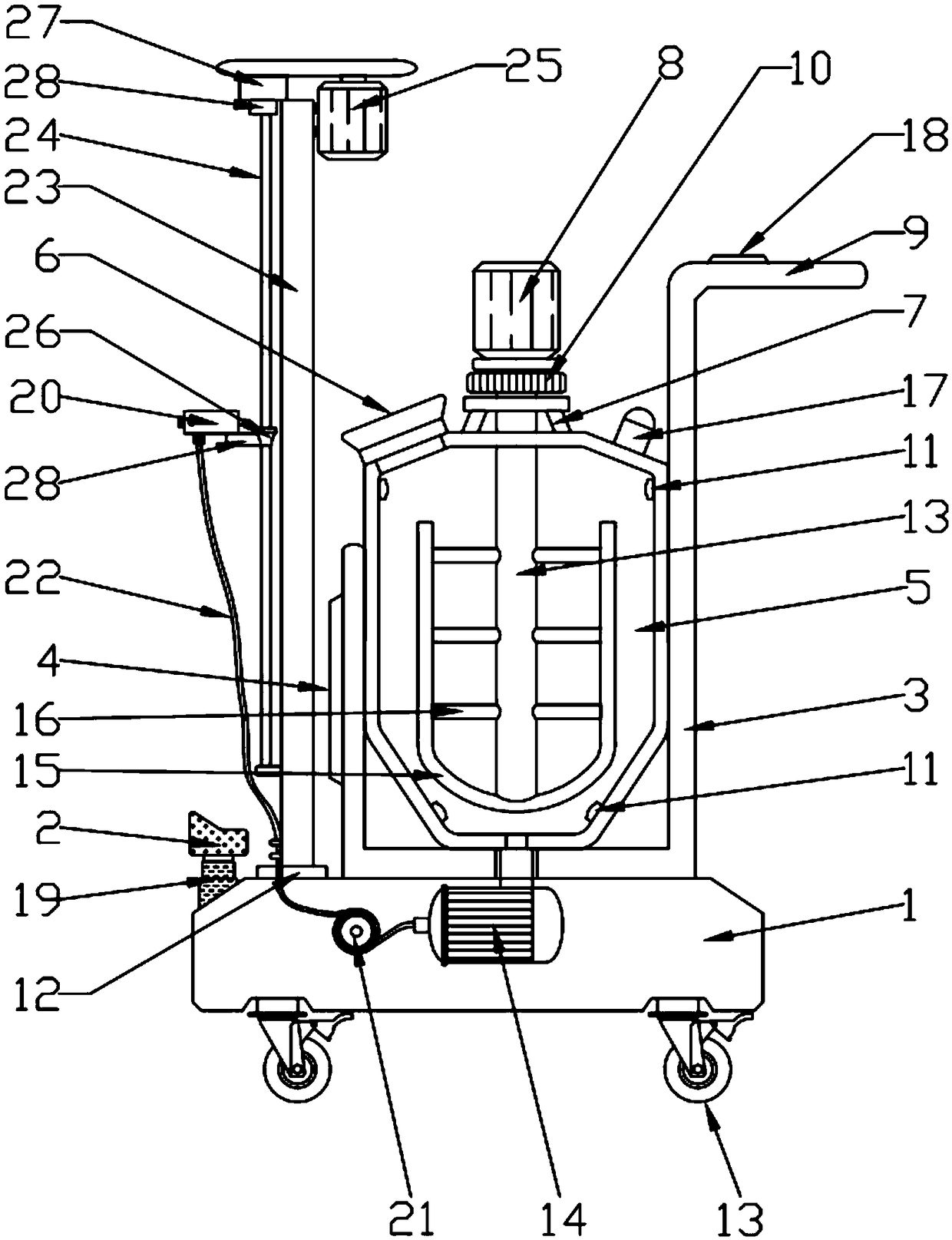

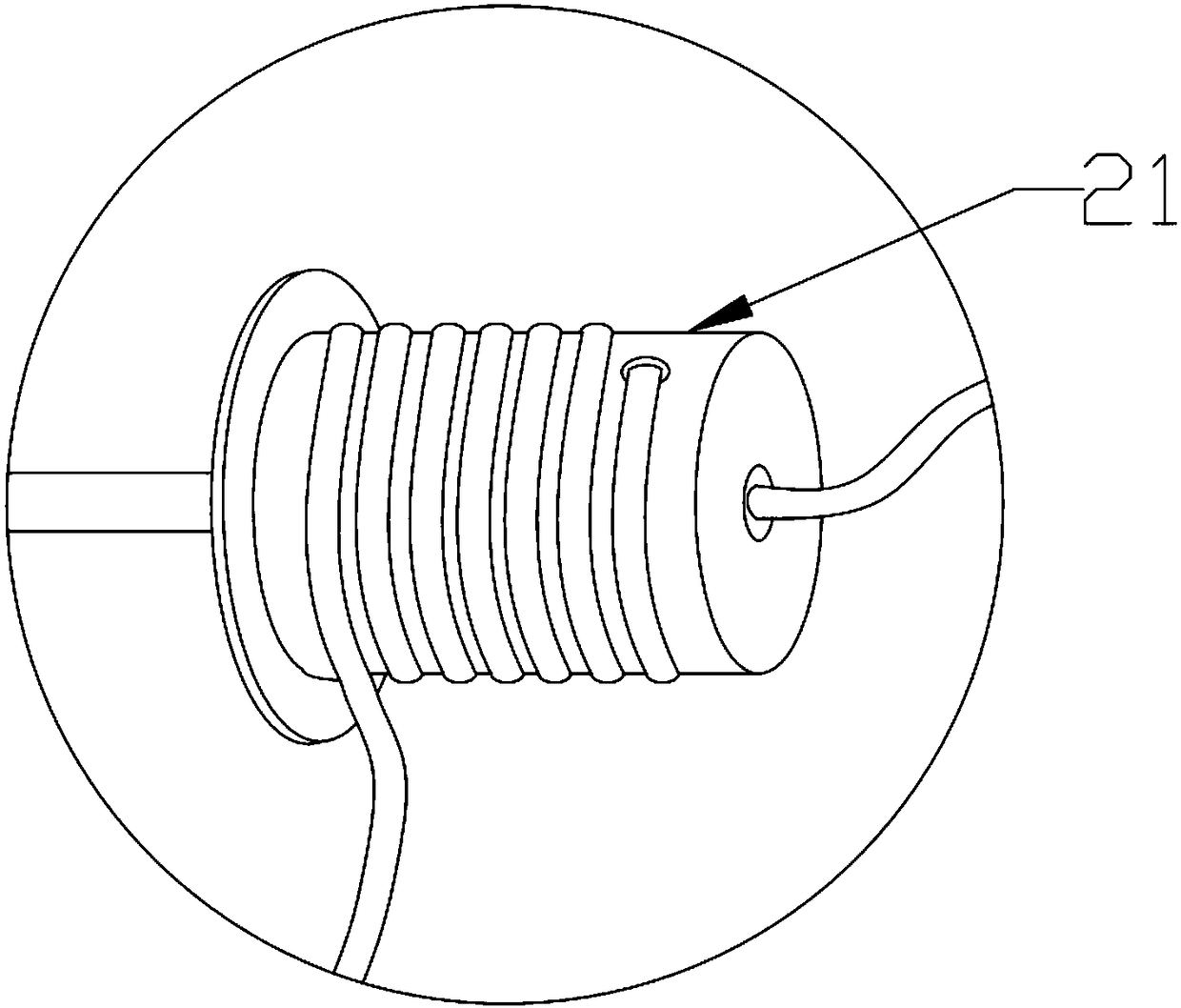

[0021] like figure 1 Shown is an automatic spraying device with stirring function, which includes a device base 1, a support frame 3, a paint storage kettle 5 and a spraying mechanism; the device base 1 is fixed with a support frame 3, and the inside of the support frame 3 is close to A paint storage kettle 5 is fixed, and a frame 7 is installed at the central position of the top of the paint storage kettle 5, and a speed reducer 10 is installed above the frame 7, and a stirring motor 8 is arranged above the speed reducer 10, and the stirring motor The output end of 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com