Decontaminating fire fighting truck with functions of automatic filling decontaminating original agent and stirring

An automatic filling and fire truck technology, applied in fire rescue, etc., can solve the problems of unfavorable decontamination fire truck combat efficiency, high manual labor intensity, and long time-consuming, so as to save manpower, reasonable structure layout, and short time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

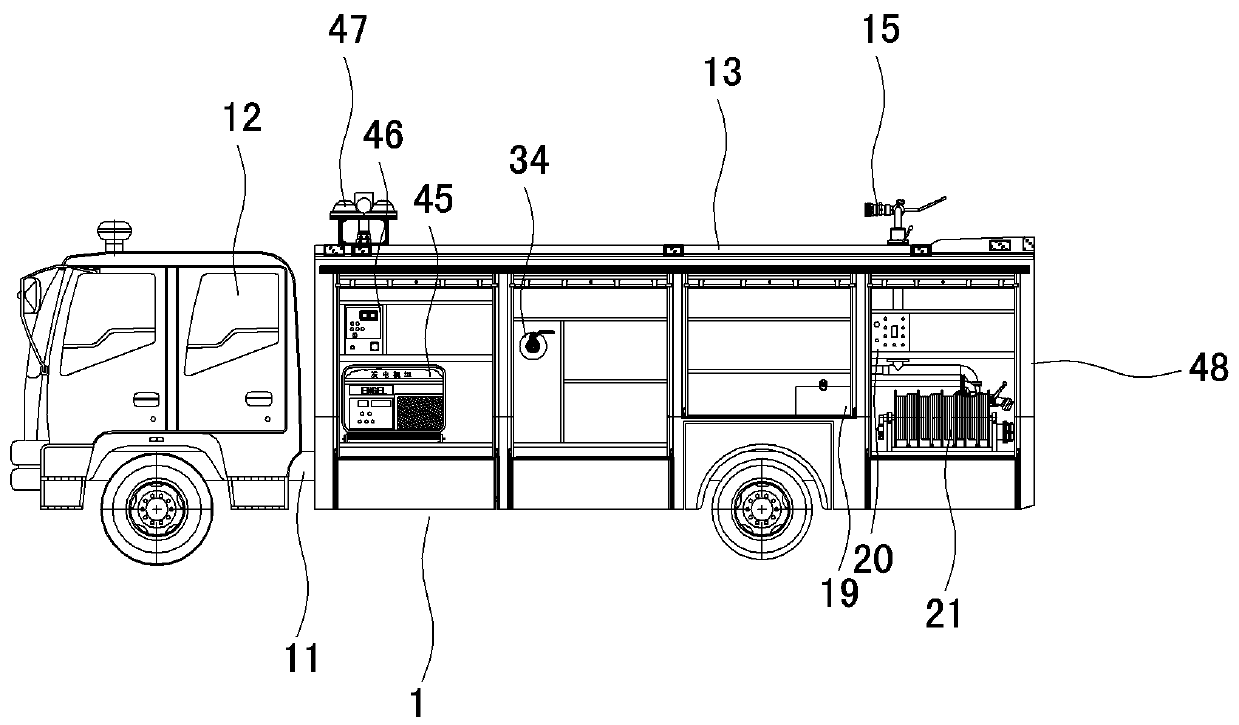

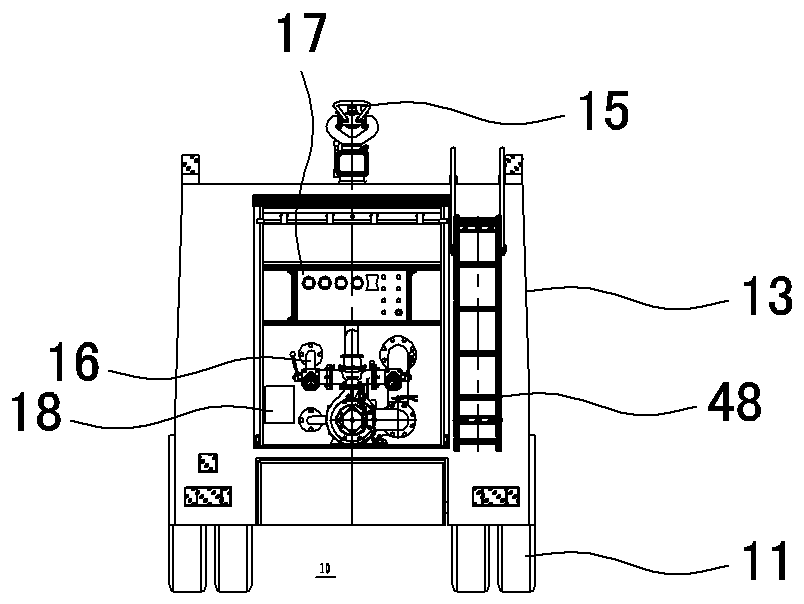

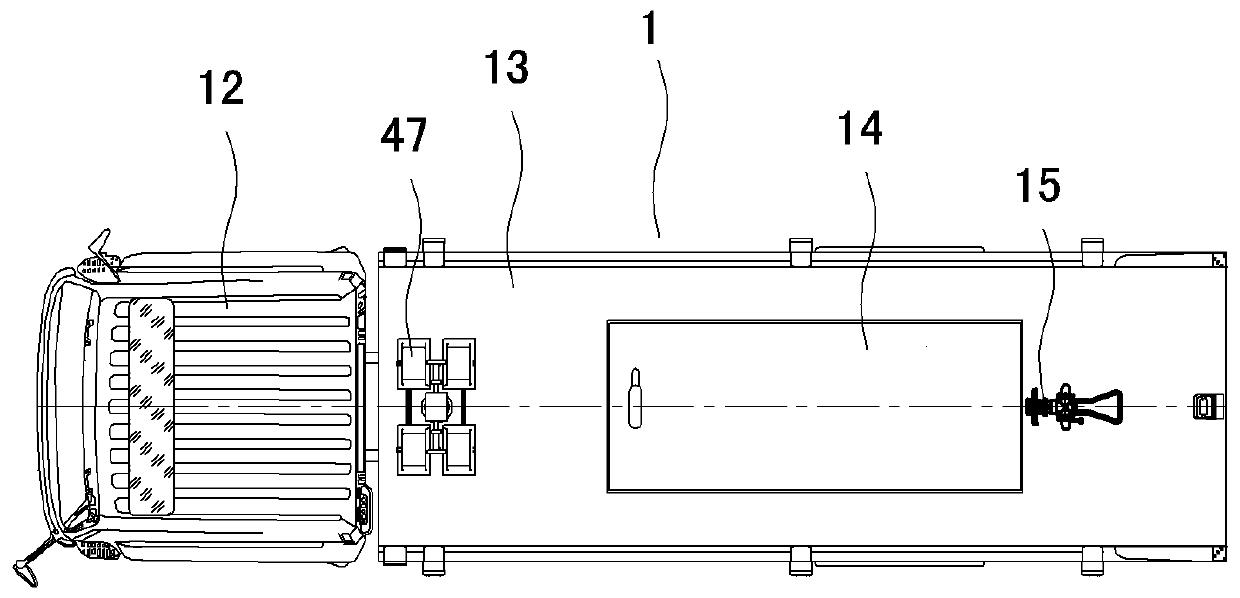

[0010] like figure 1 , figure 2 , image 3 As shown, it includes a decontamination fire truck body 1, and the decontamination fire truck body 1 includes a chassis 11 and a driver's cab 12 and a box body 13 installed on the chassis 11, and the inside of the box body 13 is provided with a decontamination liquid tank 14 The top of the box body 13 is equipped with a fire monitor 15, and the rear of the box body 13 is equipped with a fire pump 16, a fire pump control panel 17, a burner 18, a fuel tank 19, and a combustion system control panel 20, and the rear of the box body 13 is symmetrical on both sides Reel 1 21 and reel 2 22 are respectively installed at the positions, and a decontamination circulation device is provided in the body 1 of the decontamination fire truck. Pipe interface 26, pressure gauge 27, water injection valve 28, water outlet valve 29, decontamination spraying valve 30 and decontamination water spraying device 31 constitute, the water inlet of water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com