Garbage recycling, sorting and packaging system capable of automatic lubrication and working process thereof

An automatic lubrication and garbage technology, applied in garbage collection, garbage cleaning, solid waste removal, etc., can solve the problems of time-consuming, labor-intensive, low degree of automation, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

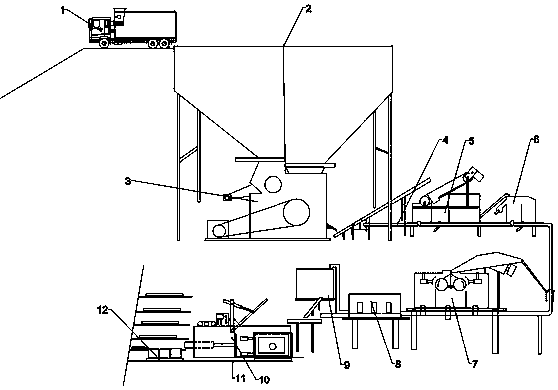

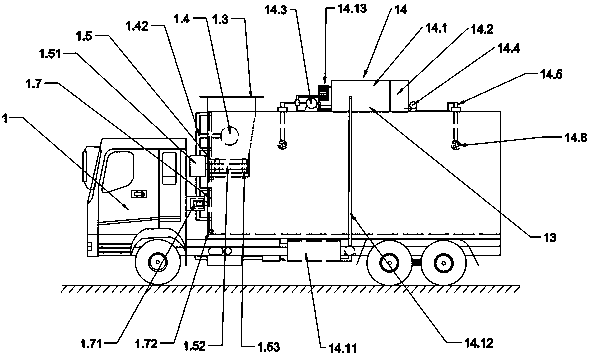

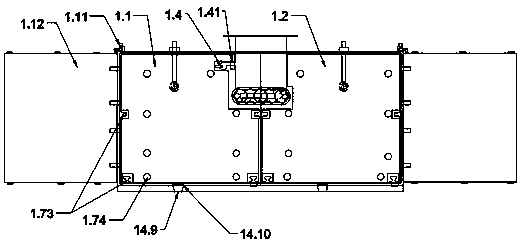

[0050] As shown in the accompanying drawings of the description, a garbage recycling, sorting and packaging system capable of automatic lubrication includes a garbage transport vehicle 1, a garbage temporary storage bin 2, a crushing device 3, a conveying device 4, a belt-type inclined net transportation and sorting device 5, Secondary wind separation device 6, electric power separation device 7, secondary magnetic separation device 8, non-ferrous metal color temporary storage warehouse 9, compression packaging device 10, transport pallet truck 12, disinfection device 13 and automatic lubrication device 16; The middle position of the interior of the compartment of the garbage recovery vehicle 1 is horizontally separated into a magnetic metal bin 1.1 and a garbage mixing bin 1.2; a hydraulic rotary door closer 1.11 is provided above the rear of the compartment of the garbage recovery truck 1, and the hydraulic rotary door closer 1.11 The swivel end is hinged to the tailgate 1.12...

Embodiment 2

[0062] The structure and principle of this embodiment 2 are basically the same as that of embodiment 1, the difference is that a scraper 1.64 is arranged above the transmission wheel 1.53, and the end of the scraper 1.64 is connected with the transmission steel belt 1.54 in a gap, and the scraper 1.64 starts To the effect of scraping off the rubbish remaining on the conveyor belt 1.54.

Embodiment 3

[0064] The structure and principle of this embodiment 3 are basically the same as that of embodiment 1. The difference is that the power separation device 7 includes a vibrating feeder 7.1, a material guide plate 7.2 and a drum electrode 7.3, and the vibrating feeder 7.1 feed end Connected with the upper end of the lifting conveyor belt III 4.4, the bottom of the discharge end of the vibrating feeder 7.1 is provided with an inverted "V"-shaped material guide plate 7.2, and the vibrating feeder 7.1 makes the feed material fall on the drum more evenly On the electrode 7.3, the sorting efficiency of the power sorting device 7 is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com