Compressing device

A pressing device and a set technology are applied in the field of tooling and fixtures, which can solve problems such as inability to be clamped and one person cannot perform normal work, and achieve the effects of facilitating pressing operations, saving labor costs, and increasing the scope of work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

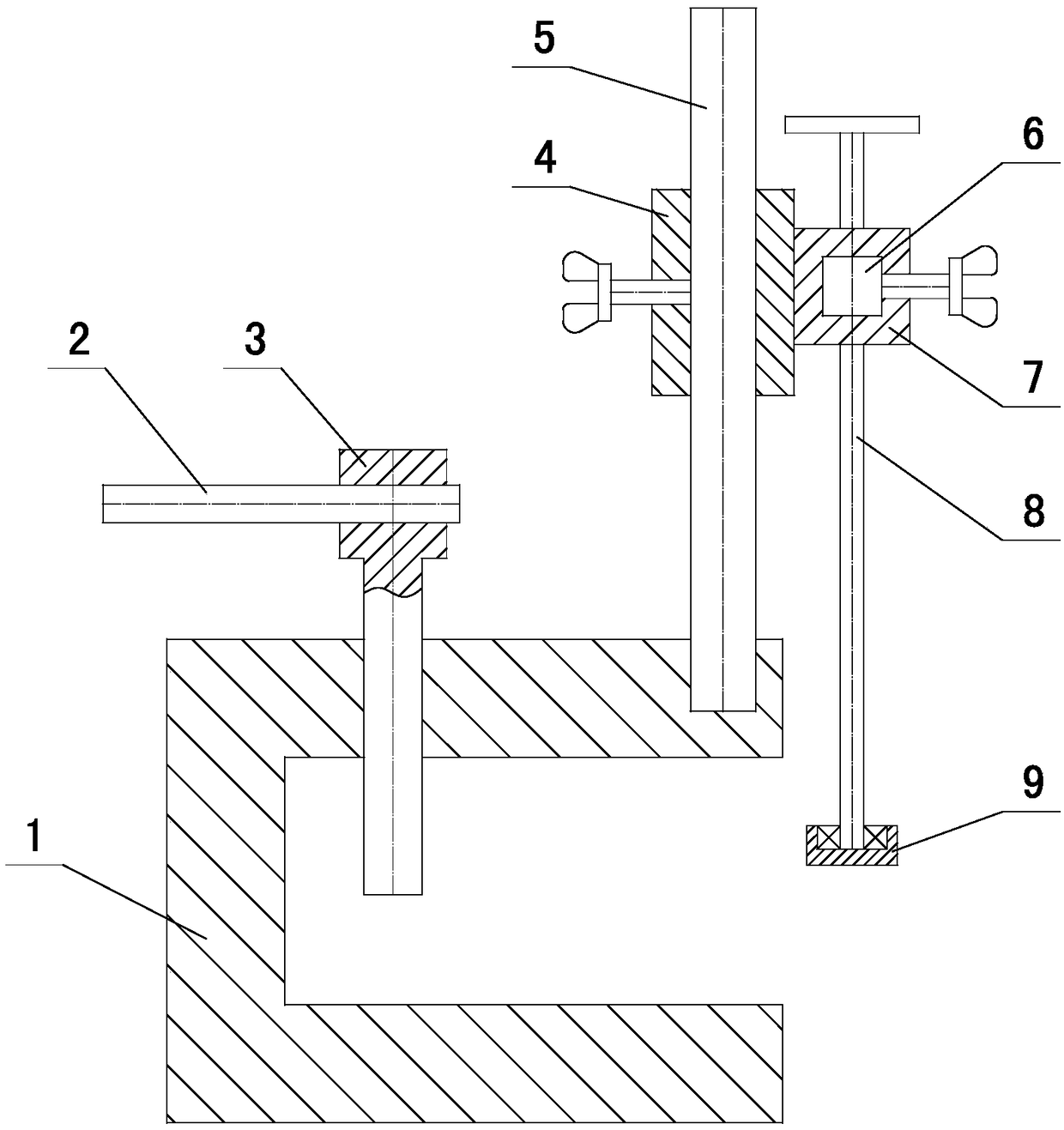

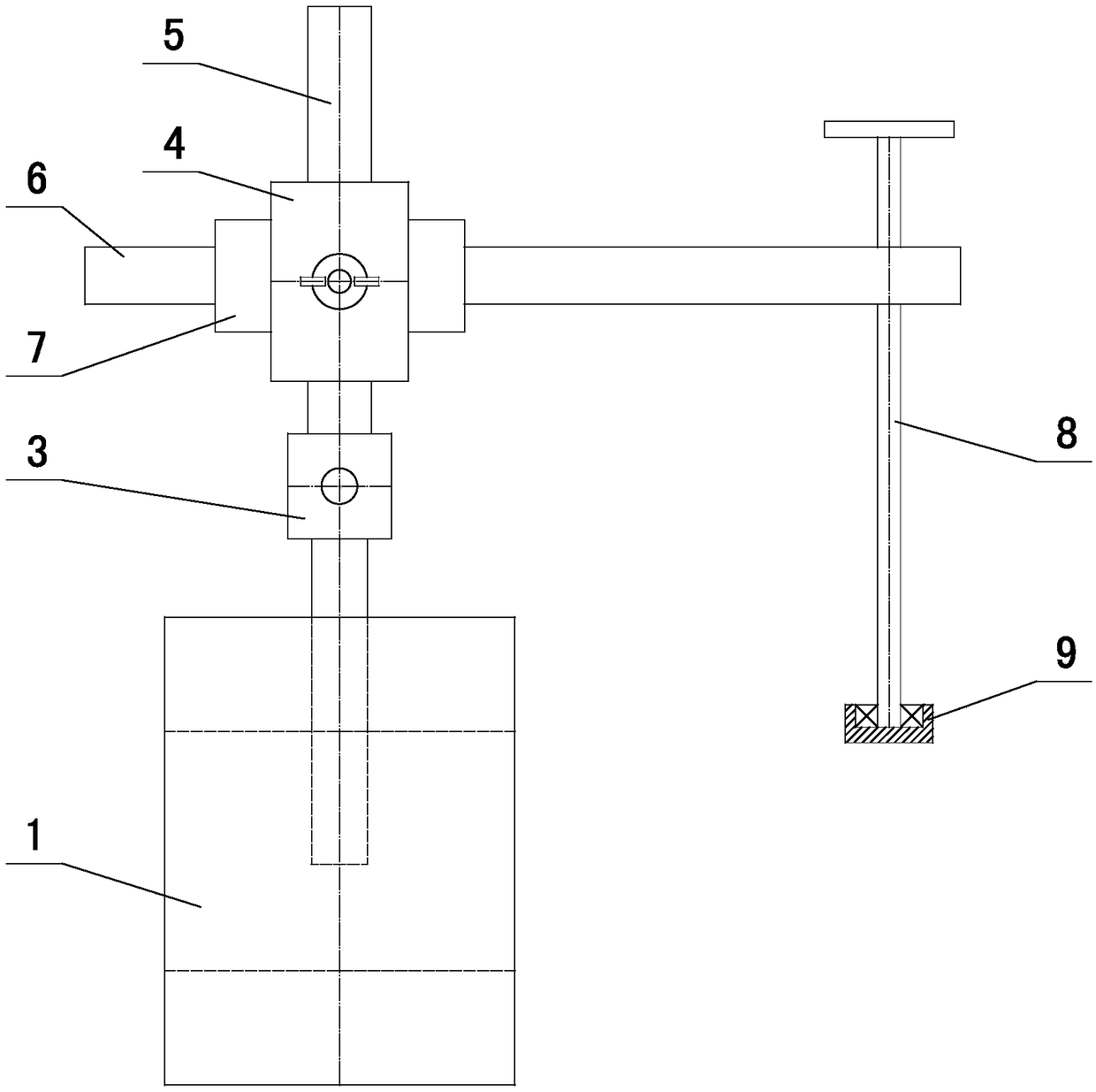

[0016] Such as figure 1 , figure 2 As shown, the pressing device includes a vise 1 arranged horizontally, and a screw mandrel 3 is vertically worn on the vise 1, and the screw mandrel 3 is installed on the vise 1 by threads, and is vertically worn on the screw mandrel 3 There is handle 2, on the vise 1 on the right side of screw mandrel 3, the first supporting rod 5 is vertically arranged, and the first supporting rod 5 is installed on the vise 1 by threads, and the first supporting rod 5 is sleeved with the first supporting rod 5. Shaft sleeve 4, on the first shaft sleeve 4, a thumb screw is vertically worn, and the first shaft sleeve 4 is fixed on the first support rod 5 through the thumb screw, and the first shaft sleeve 4 is horizontally provided with a second The second shaft sleeve 7 is equipped with a second support rod 6 in the second shaft sleeve 7, and a thumb screw is vertically worn on the second shaft sleeve 7, and the second support rod 6 is fixed on the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com