Hydraulic cigarette cinder former

A bar press, hydraulic technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of non-adjustable pressing bars, material blocking, and non-adjustable extrusion force, so as to reduce the number of types. , The effect of reducing manufacturing cost and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

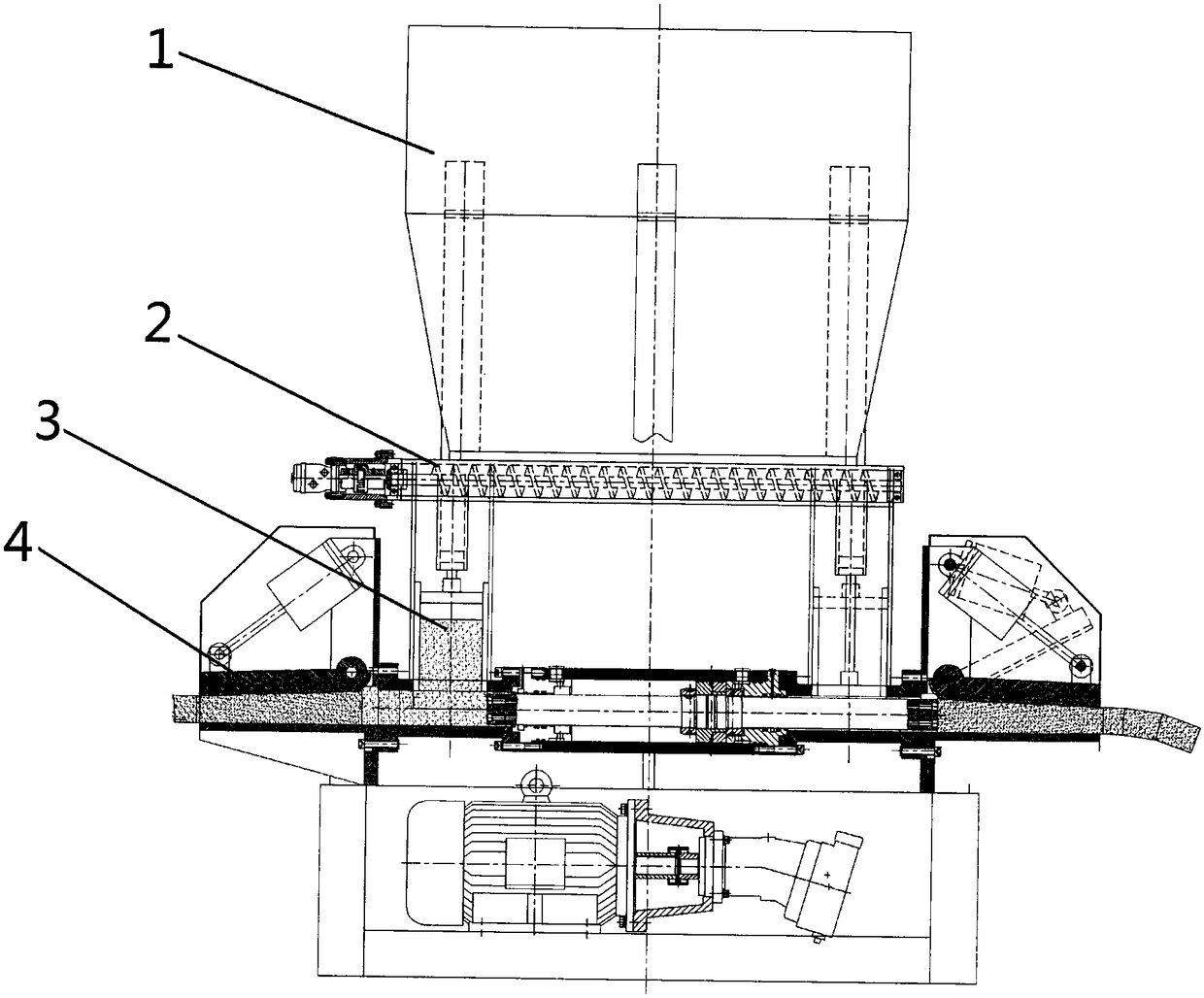

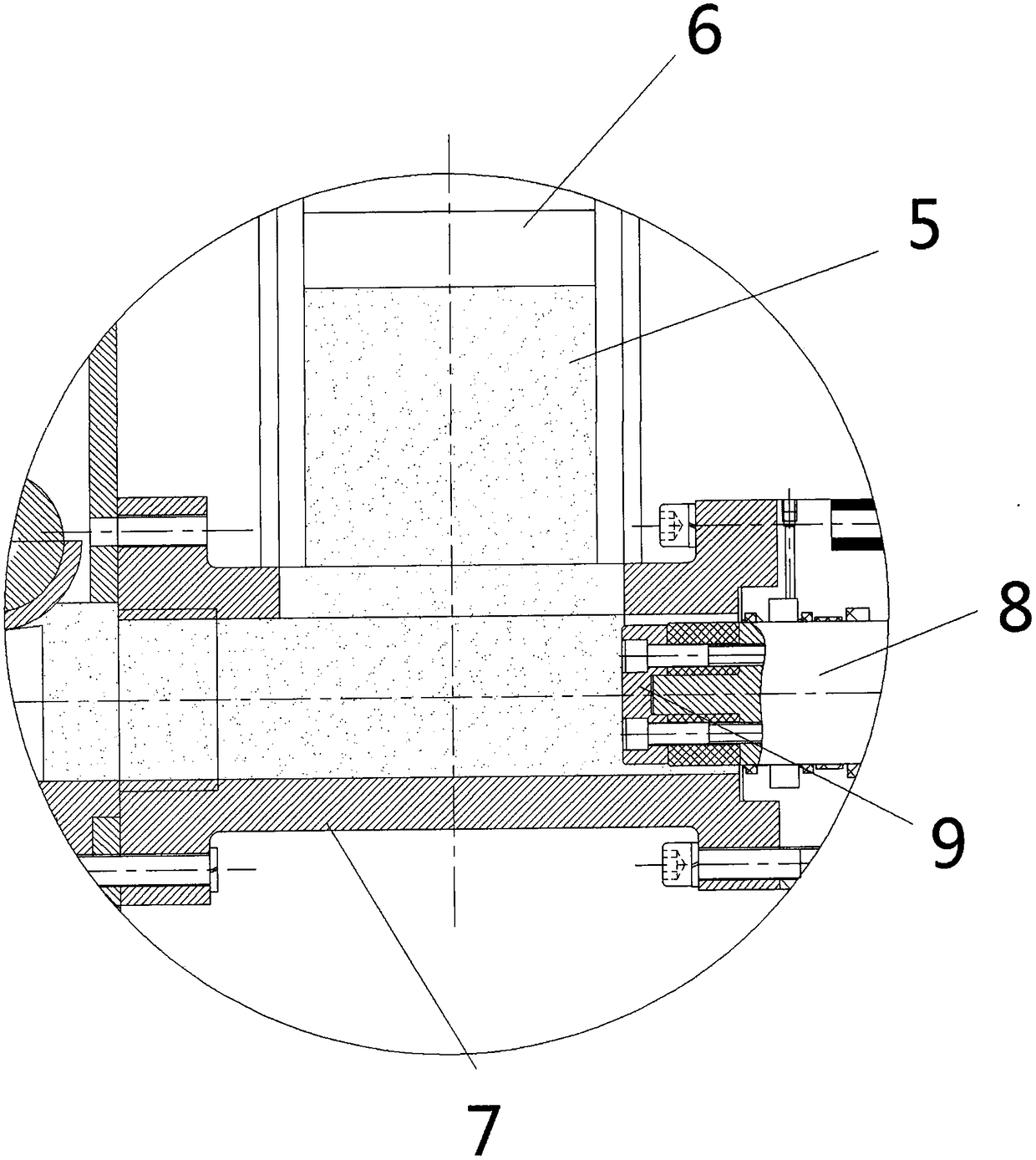

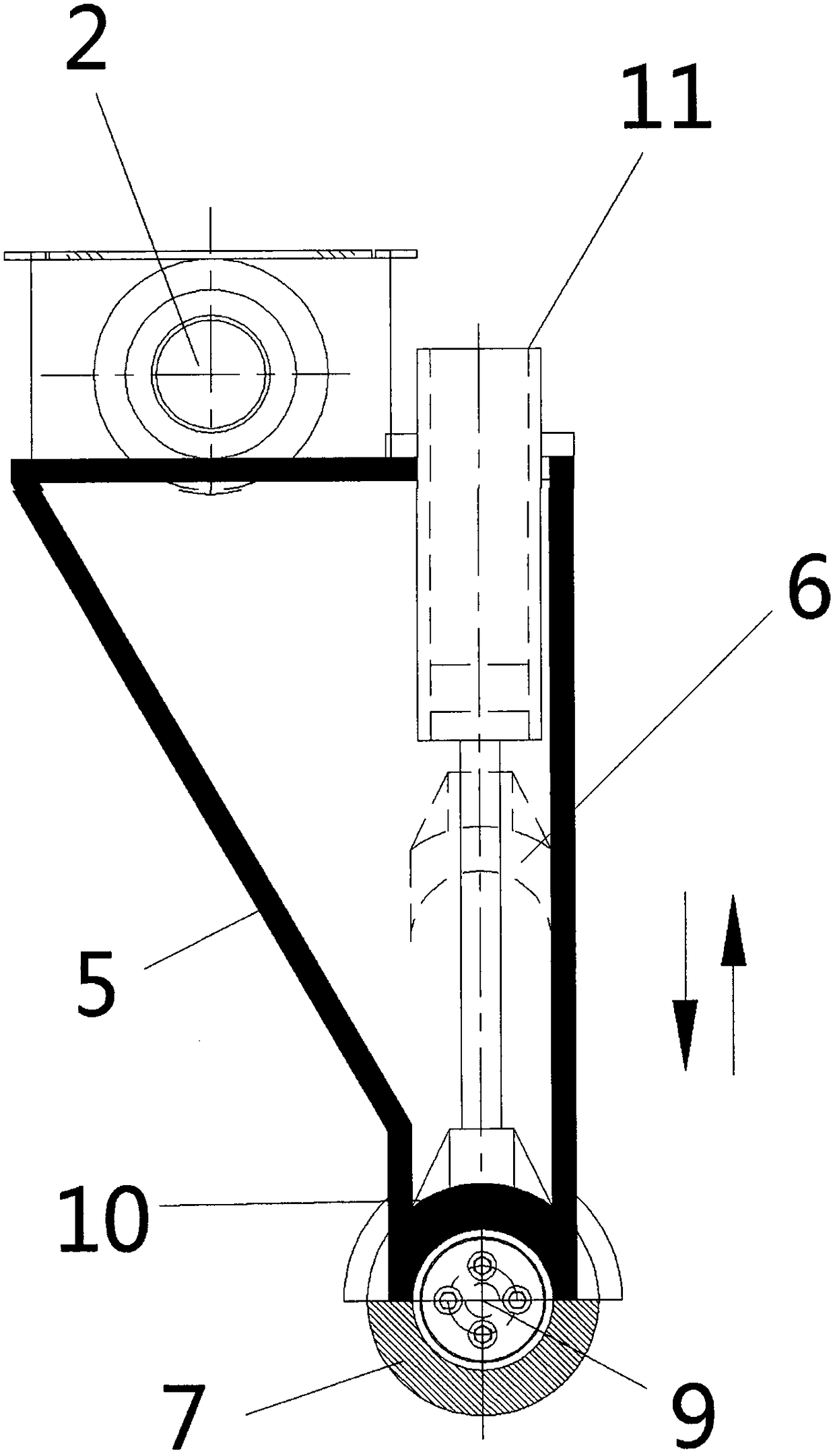

[0048] Below in conjunction with accompanying drawing, the present invention will be further described, as figure 1 with figure 2 As shown, a hydraulic rod pressing machine includes a storage bin 1, a feeding device 2, a blanking mechanism 3 and a forming mechanism 4;

[0049] The feeding device 2 is used to push the material in the storage bin 1 to the top of the blanking mechanism 3 so that the material falls into the blanking mechanism 3; the storage bin 1 is made of carbon steel, The top is a rectangular structure, and the bottom is a funnel structure. The angle between the width of the two sides of the funnel and the vertical line of the center is not more than 30°, which is convenient for the bulk materials to slide down automatically. Three sets of material level sensors can be arranged above the silo body of the storage silo 1 to detect the height of the material in the silo, and automatically instruct the equipment to perform commands such as standby, start or stop....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com