Conveying line for corrugated paper products

A technology for conveying lines and corrugated paper, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of increasing production costs and large production lines, and achieves the effect of reducing the floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

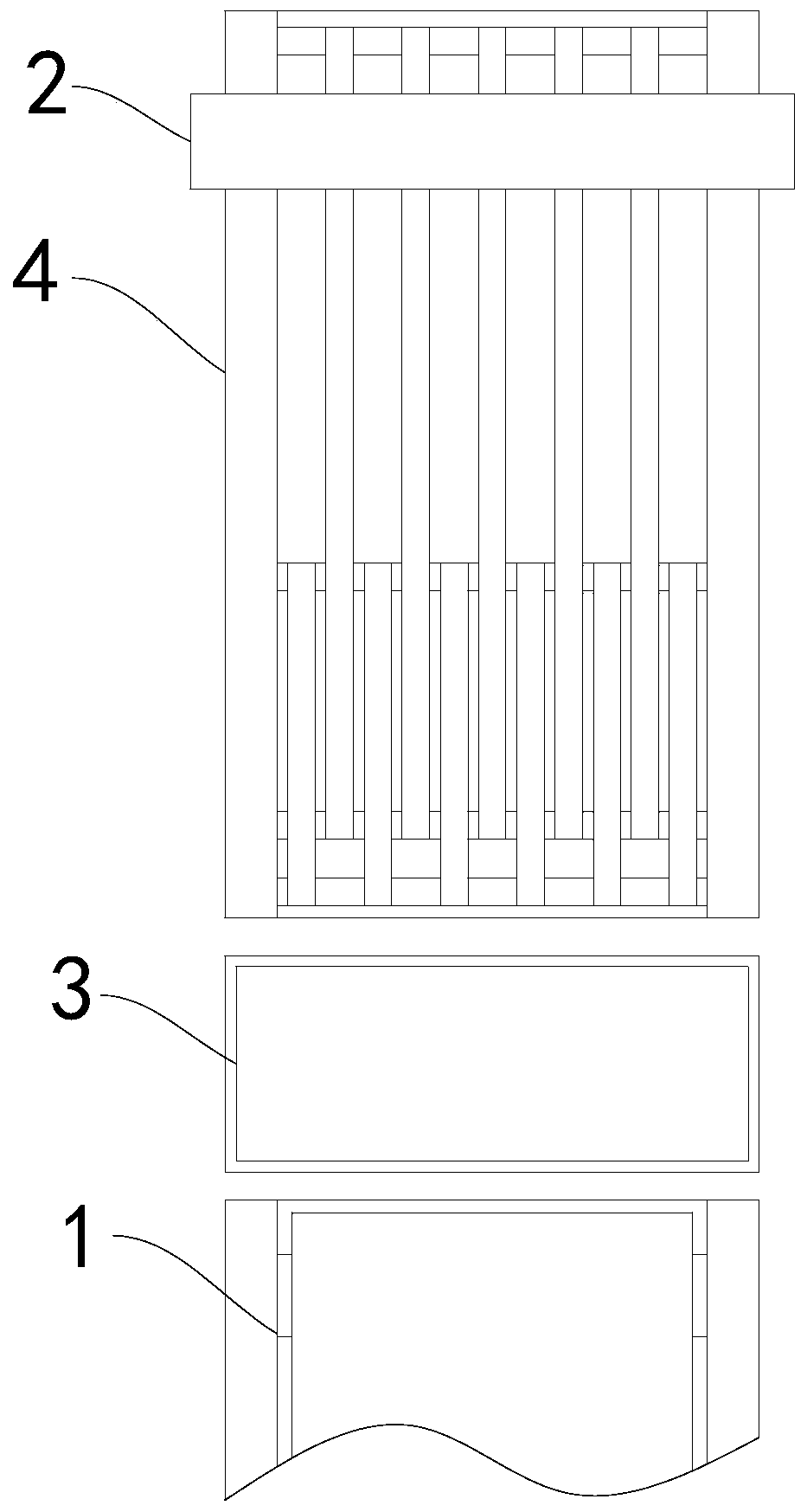

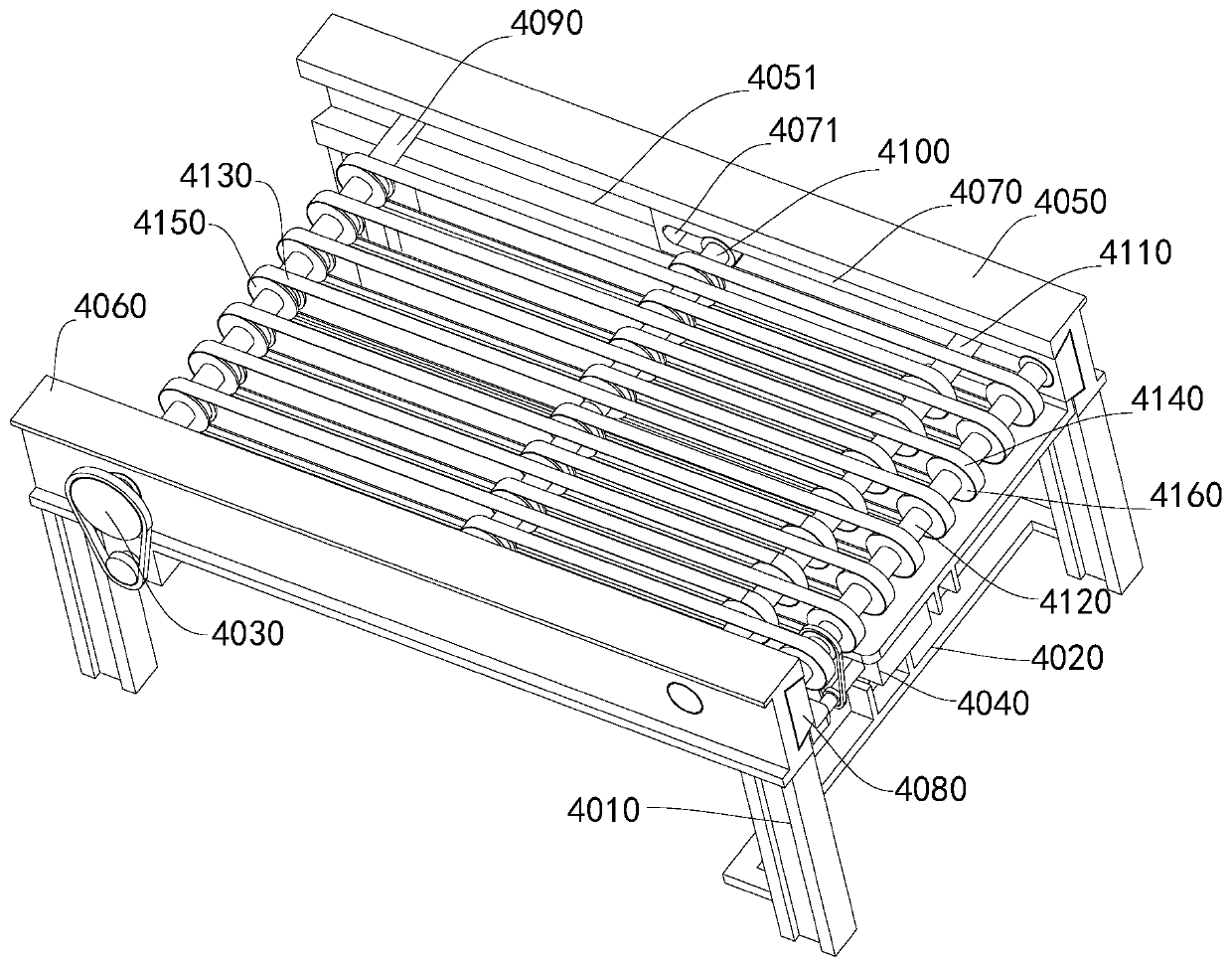

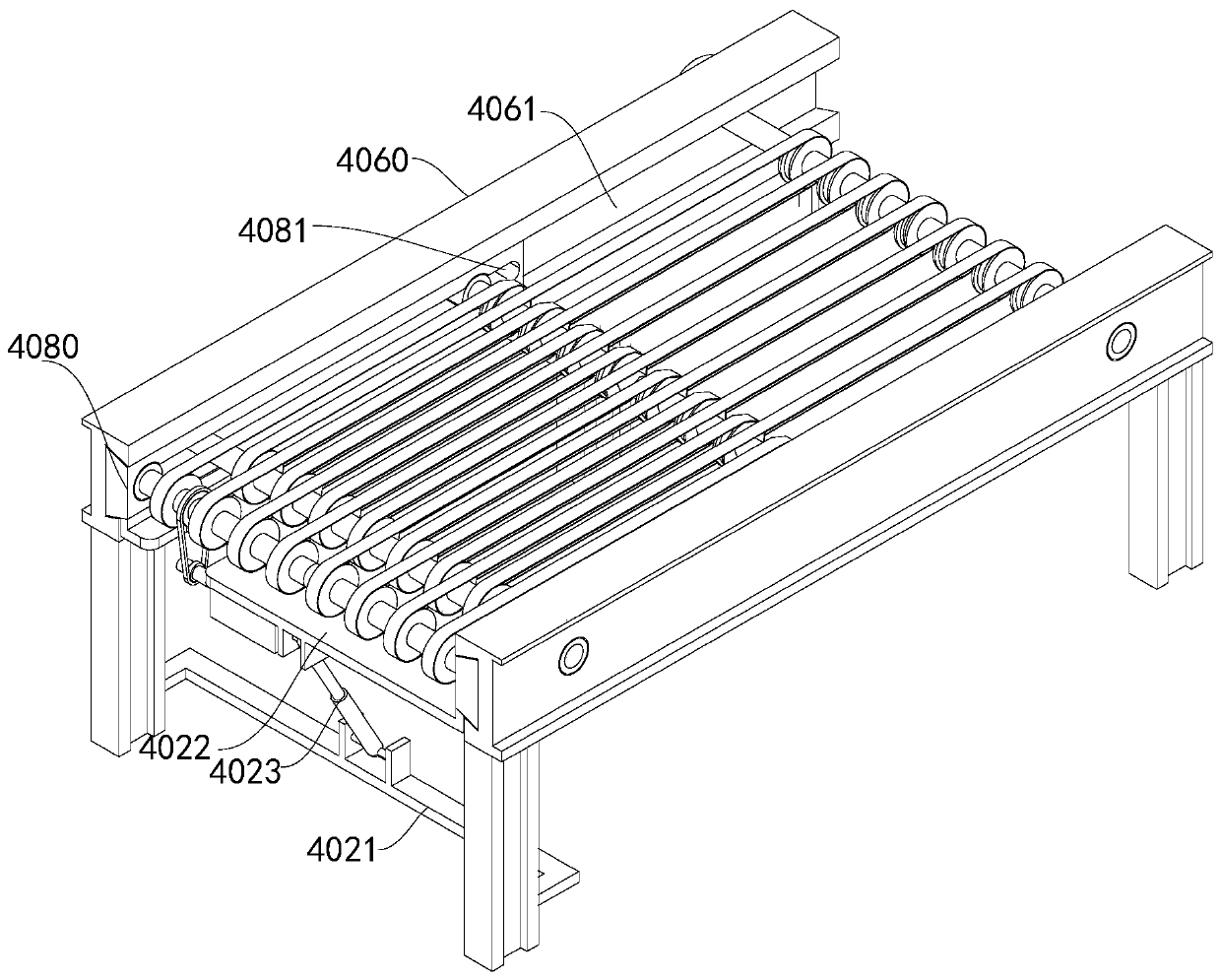

[0019] Such as figure 1 As shown, a corrugated paper product conveying line includes a qualified product conveying line 1, an image acquisition device 2, an industrial computer, a telescopic conveying line 4 and a blanking chute 3, and the products conveyed on the telescopic conveying line 4 pass through the image collecting device 2 Carry out complete image acquisition, the signal input end of image acquisition device 2 is electrically connected with the signal output end of industrial control computer, image acquisition device 2 transmits the image information to industrial control computer after collecting the product image, and the information obtained by industrial control computer and The pre-stored image info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com