Smart printing machine equipped with deviation monitoring system

A monitoring system and printing machine technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve problems such as deviation, fabric wrinkles, and the inability to ensure the uniformity of fabric material and size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention are described in detail below, but the protection scope of the present invention is not limited to the embodiments.

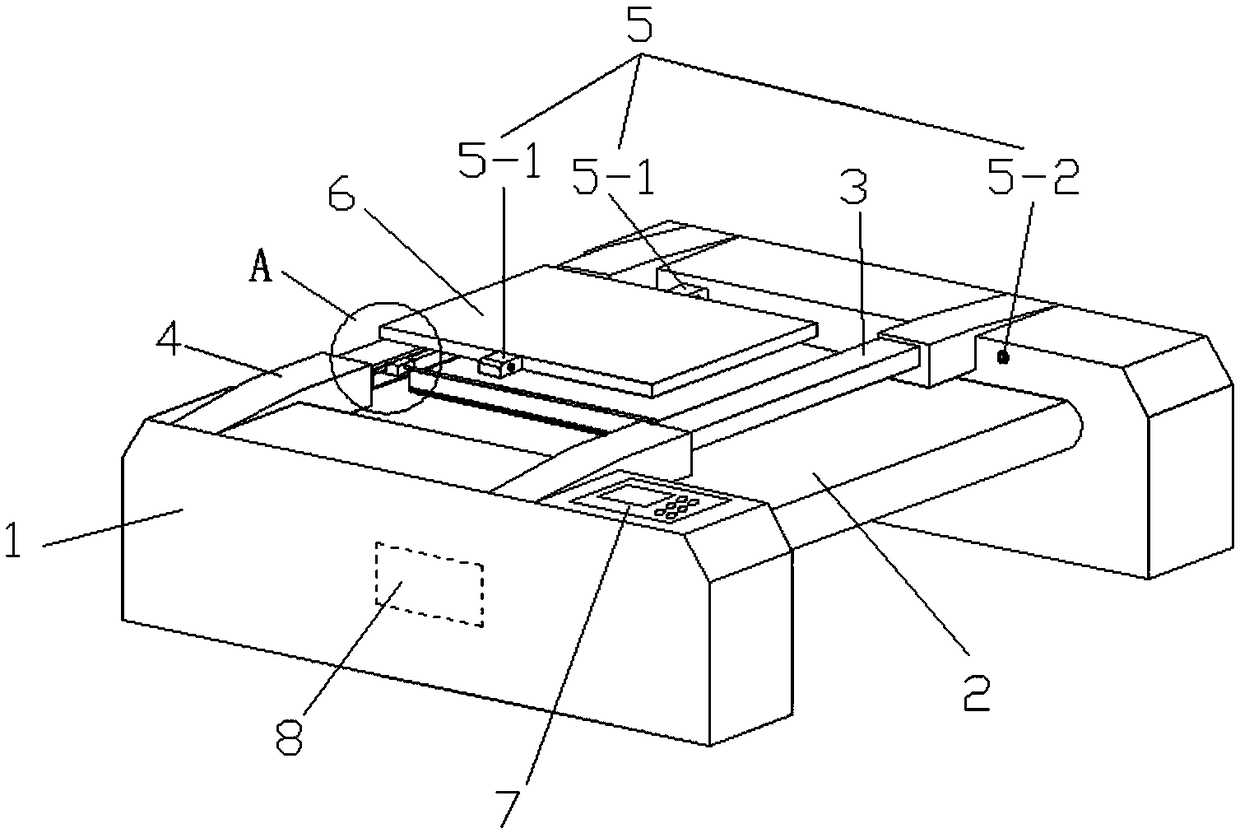

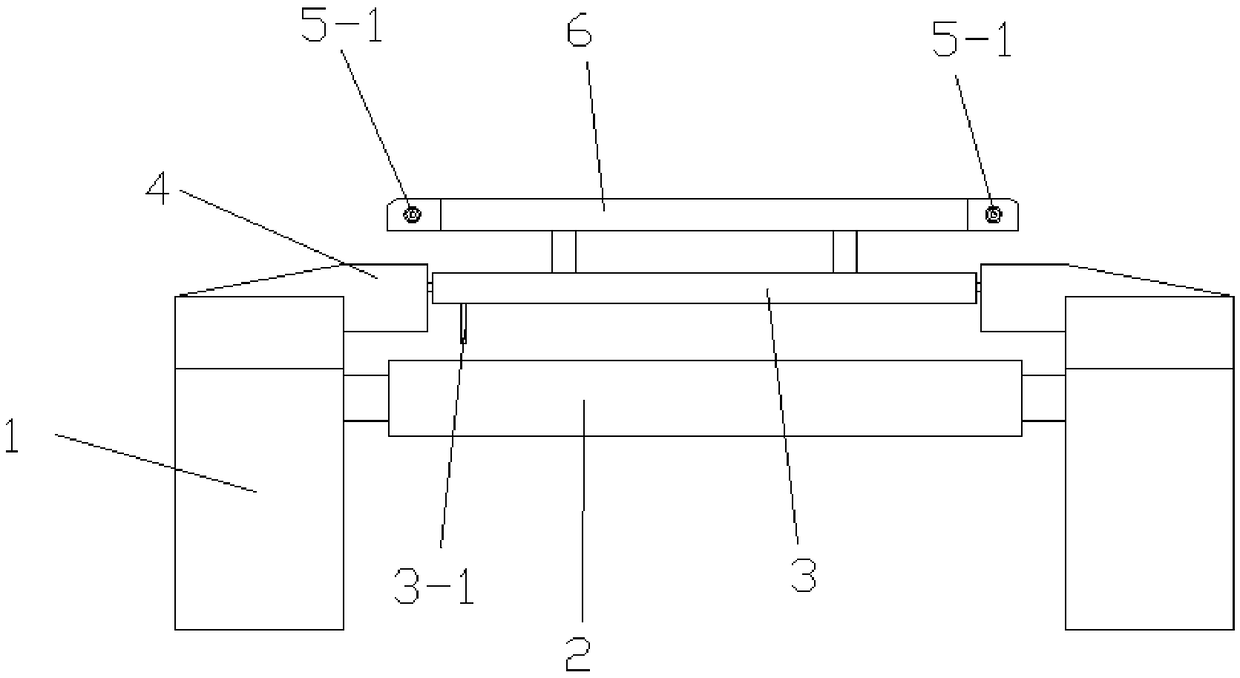

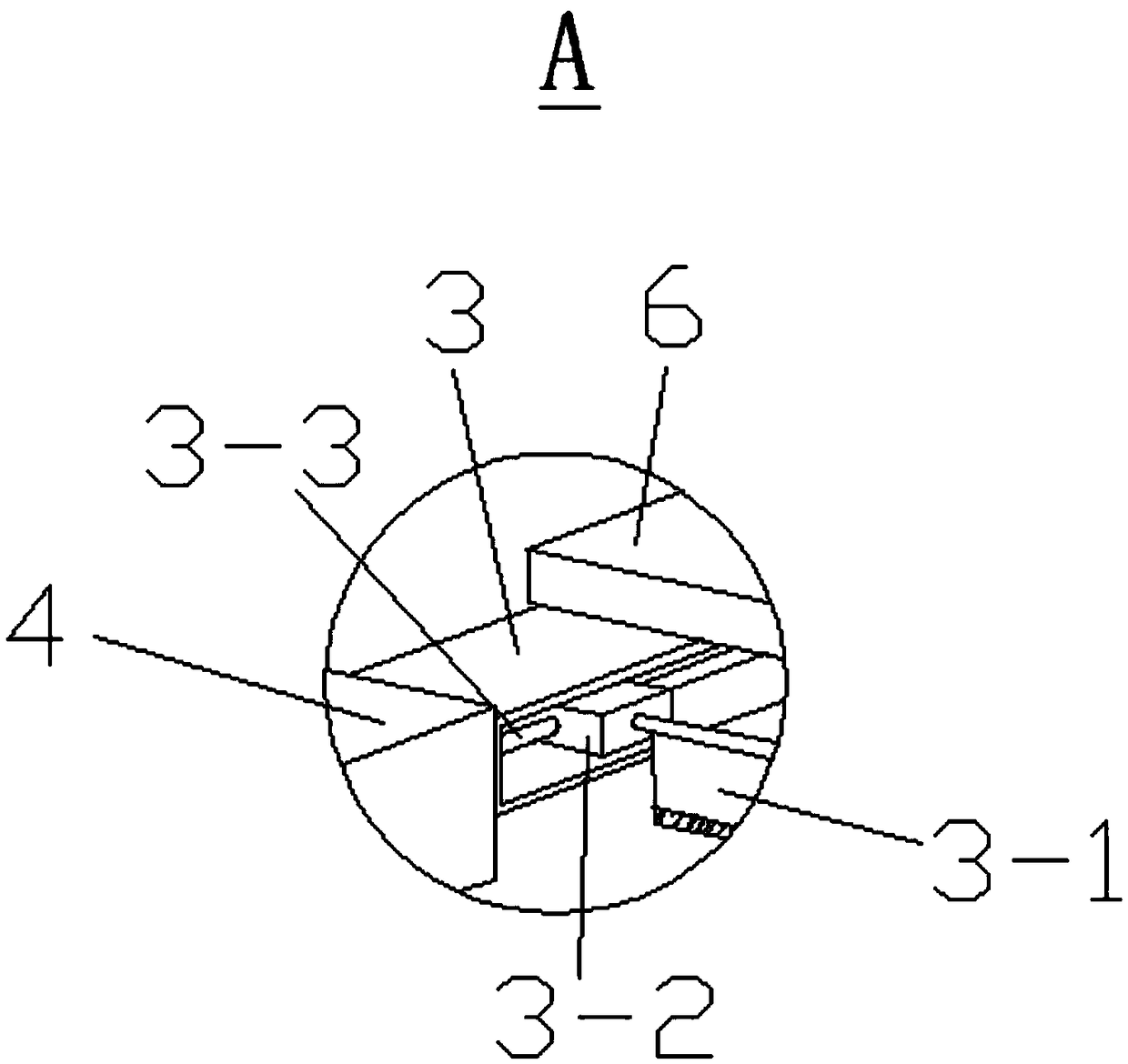

[0014] according to Figure 1 to Figure 3 As shown, an intelligent printing machine with a deviation monitoring system includes a frame 1, a guide belt 2, a support platform 6, a control module, a monitoring module, and a printing and dyeing module. The printing and dyeing module includes a scraper guide rail 3, a support guide rail 4. The mobile device 3-2 and the printing and dyeing scraper 3-1, the two ends of the guide belt 2 are connected to the frame 1, the two ends of the printing and dyeing scraper 3-1 are connected to the moving The device 3-2 is connected, the moving device 3-2 is arranged inside the scraper guide rail 3 and connected with the rail shaft 3-3, the scraper guide rail 3 is connected with the support guide rail 4, and the The support platform 6 is arranged above the scraper guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com