Automatic dye spraying device for textile printing and dyeing

An automatic spraying and textile printing and dyeing technology, which is applied in the direction of textile material equipment configuration, textile material processing, textile material drum processing, etc., can solve the problems of fabric printing and dyeing, poor printing and dyeing effect, short contact time, etc., to achieve enhanced The effect of printing and dyeing speed, improving printing and dyeing efficiency, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

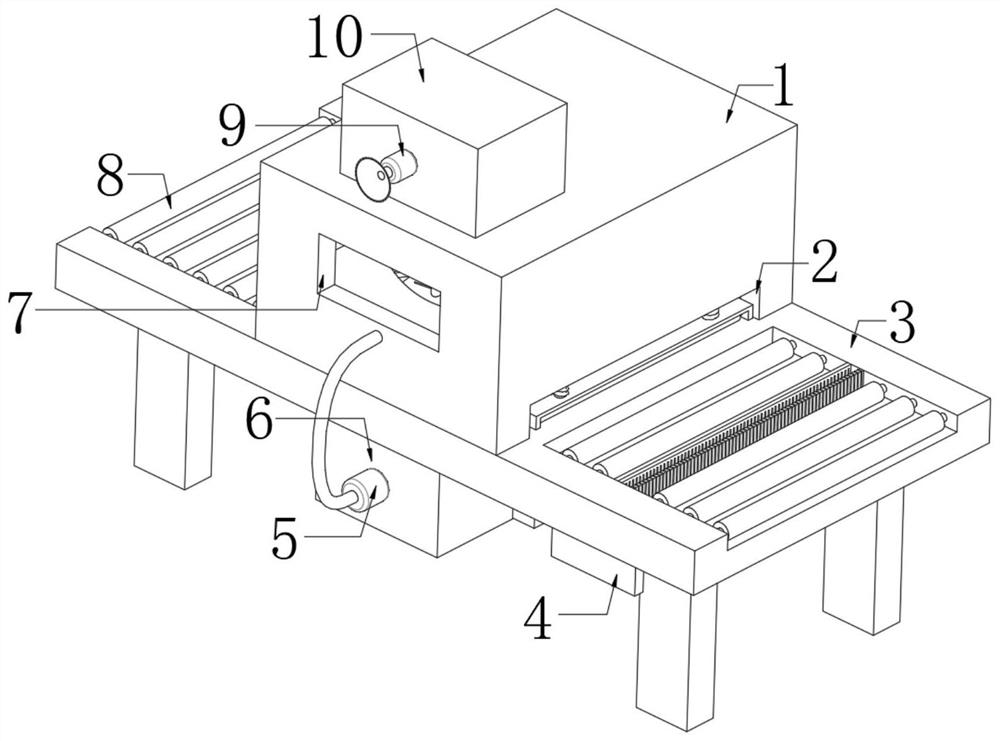

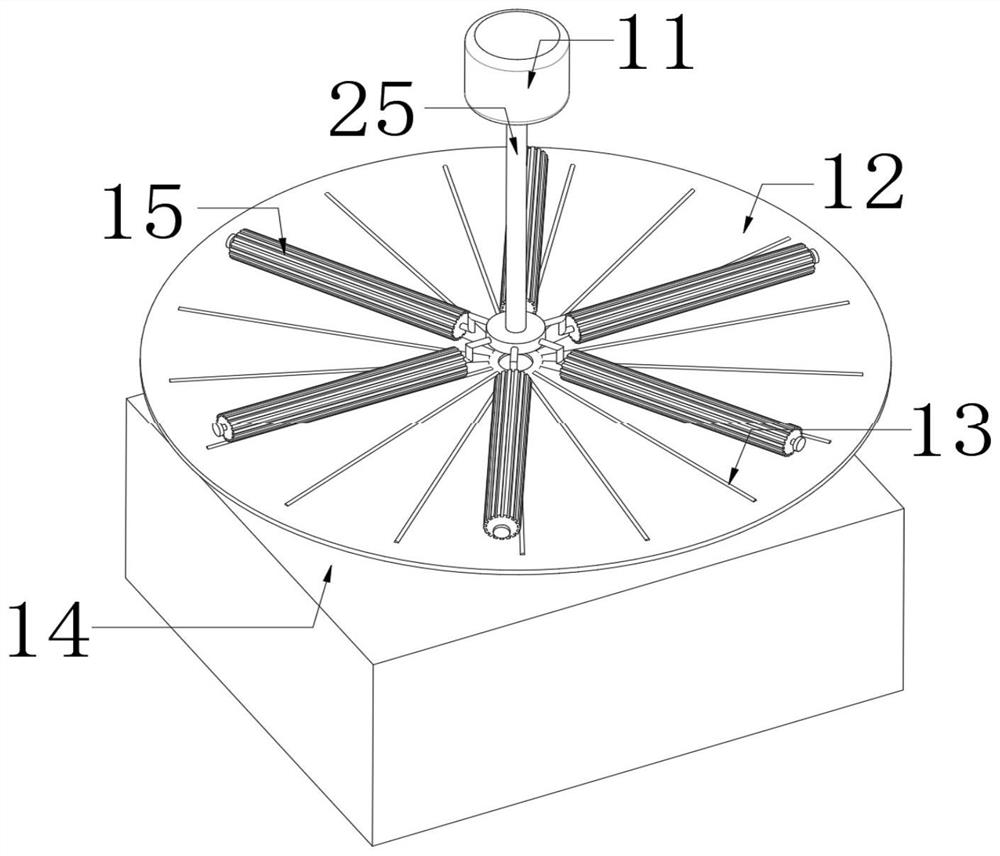

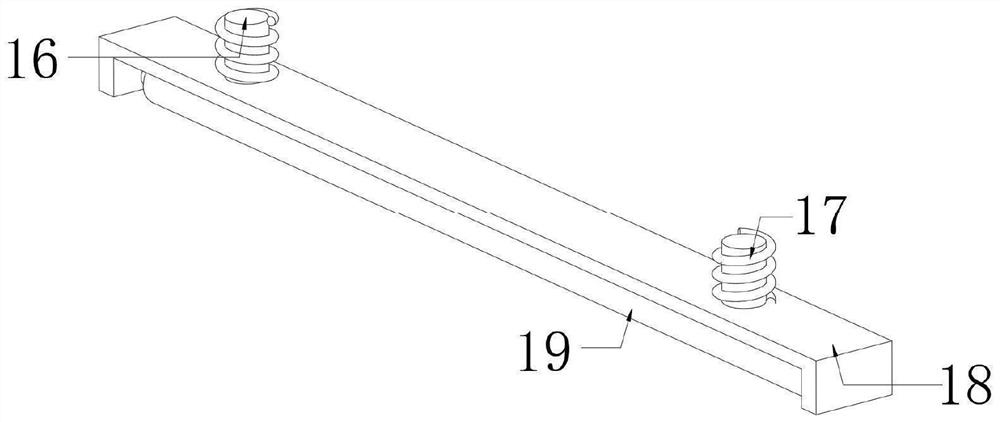

[0031] refer to Figure 1-6 , an automatic dye spraying device for textile printing and dyeing, comprising a workbench 3, a printing and dyeing box 1 is fixed on the top outer wall of the workbench 3 by bolts, a motor 11 is fixed on the top outer wall of the printing and dyeing box 1 by bolts, and the output shaft of the motor 11 passes through The coupling is connected with a rotating rod 25, the outer wall of the rotating rod 25 is fixed with connecting rods distributed equidistantly by bolts, one end of the connecting rod is connected with a printing and dyeing roller 15 through a bearing, and the top outer wall of the workbench 3 is fixed with a circular plate 12 by bolts. , the top outer wall of the circular plate 12 is provided with a conical printing and dyeing tank, and the inner wall of the conical printing and dyeing tank is fixed with equidistant retaining strips 13 by bolts, the top outer wall of the printing and dyeing box 1 is provided with an air blowing mechanis...

Embodiment 2

[0042] refer to Figure 7 , an automatic dyeing device for textile printing and dyeing. Compared with Embodiment 1, this embodiment also includes a support plate 29 fixed on the top outer wall of the workbench 3 by bolts, and a scraper fixed on the bottom outer wall of the support plate 29 by bolts. The plate 30 and the bottom outer wall of the workbench 3 are fixed with a dirt collection box 31 by bolts, and the scraper 30 is used in conjunction with the dirt collection box 31.

[0043] During use, some dye may remain inside the cloth after the cloth is printed and dyed through the printing and dyeing box 1. At this time, the excess dye can be scraped off by the scraper 30 under the support plate 29, and the scraped dye enters the dirt collection box 31 Collecting in the middle can prevent color crossing between fabrics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com