Dyeing and finishing equipment and process for knitted antibacterial underwear fabric

An underwear fabric, dyeing and finishing technology, applied in the field of fabric dyeing and finishing, can solve problems such as general dimensional stability, and achieve the effect of improving the dyeing effect, improving stability and preventing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

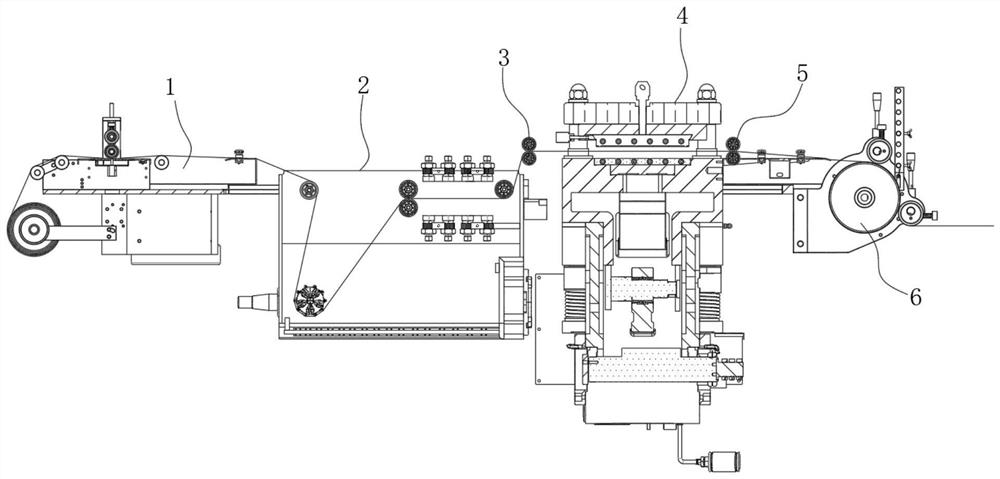

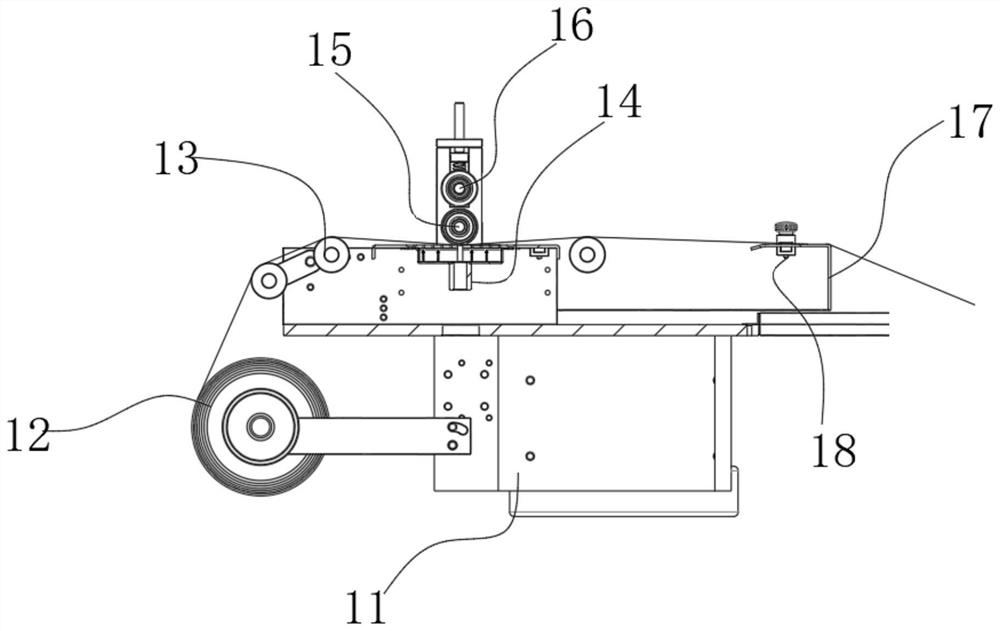

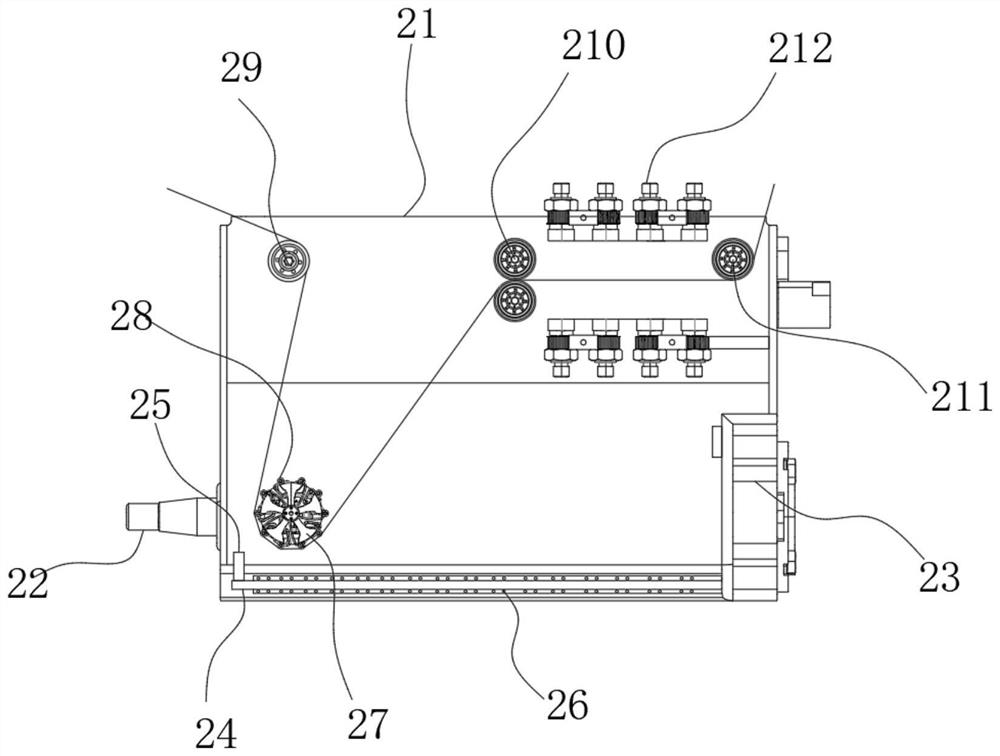

[0044] see Figures 1 to 4 , the present invention provides a dyeing and finishing equipment for knitted antibacterial underwear fabric, including:

[0045] A leveling and anti-chip assembly 1, which can provide the fabric to be dyed and finished, and perform a leveling and anti-chip treatment on it;

[0046] A printing and dyeing component 2, which is connected to one side of the leveling and anti-dust component 1, and is used for printing and dyeing the fabric from the leveling and anti-dust component 1;

[0047] A drying and leveling component 4, which is connected to one side of the printing and dyeing component 2, and is used for drying the knitted antibacterial underwear fabric from the printing and dyeing component 2; and

[0048] Receiving component 6.

[0049] That is to say, in this embodiment, a leveling and dedusting component 1 is provided, which can perform leveling and dedusting treatment on the fabric before printing and dyeing, so as to ensure the cleanlines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com