A high-stretch mixed textile fabric rapid flattening synchronous printing and dyeing equipment

A technology for textile fabrics and printing and dyeing equipment, which is applied in the field of rapid flattening and synchronous printing and dyeing equipment for high-stretch mixed textile fabrics. problems, to achieve the effect of improving the printing and dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Based on the embodiments in the present invention, all other embodiments obtained by ordinary technical personnel in the art under the premise of not creating creative labor belong to the protection of the present invention.

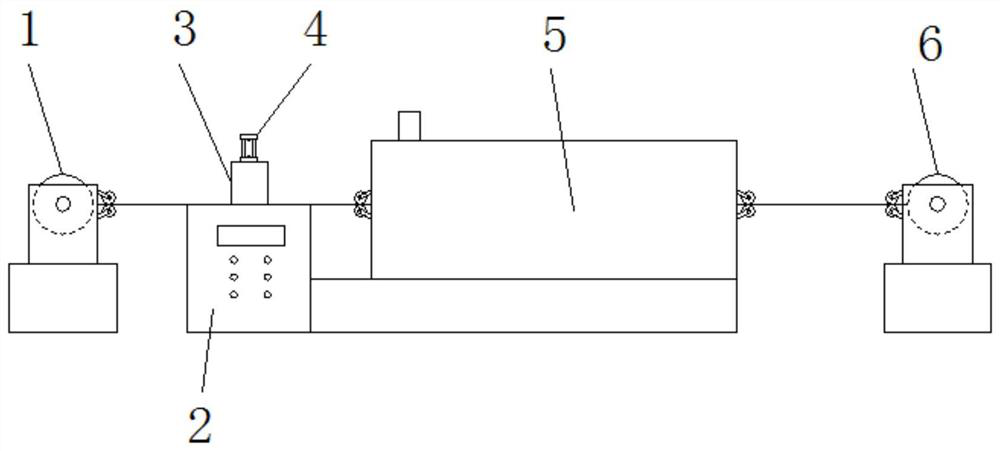

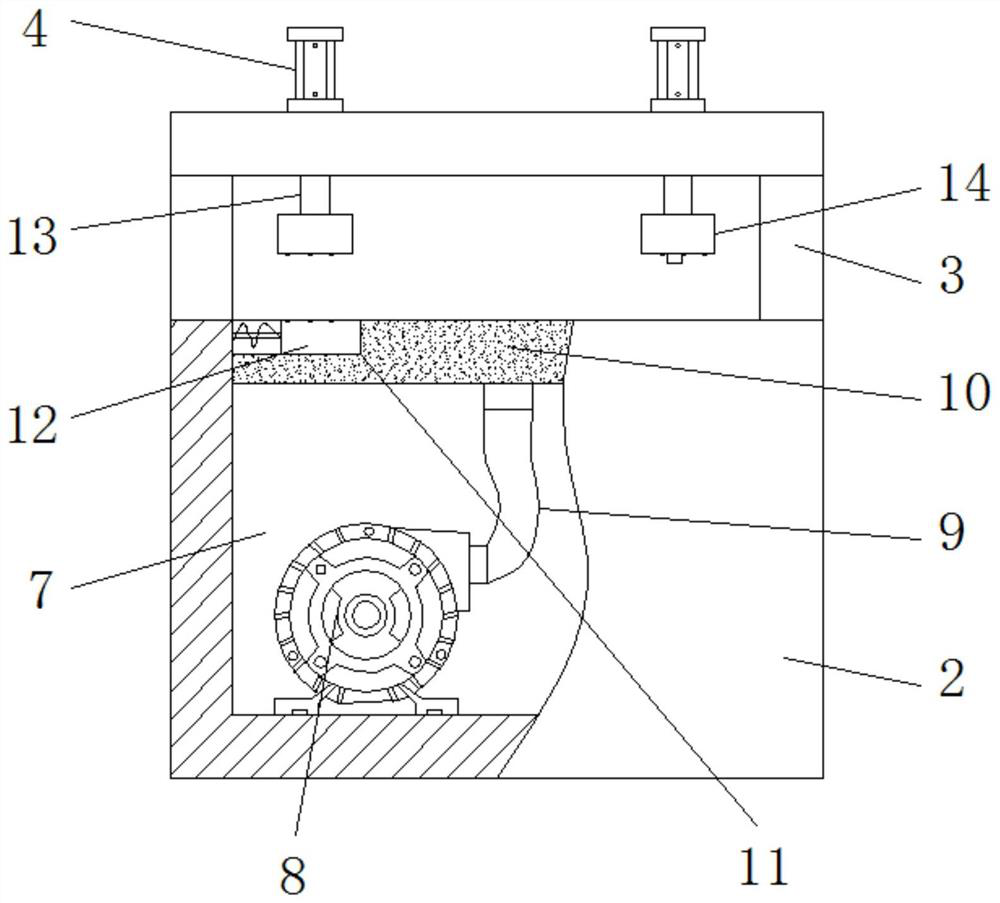

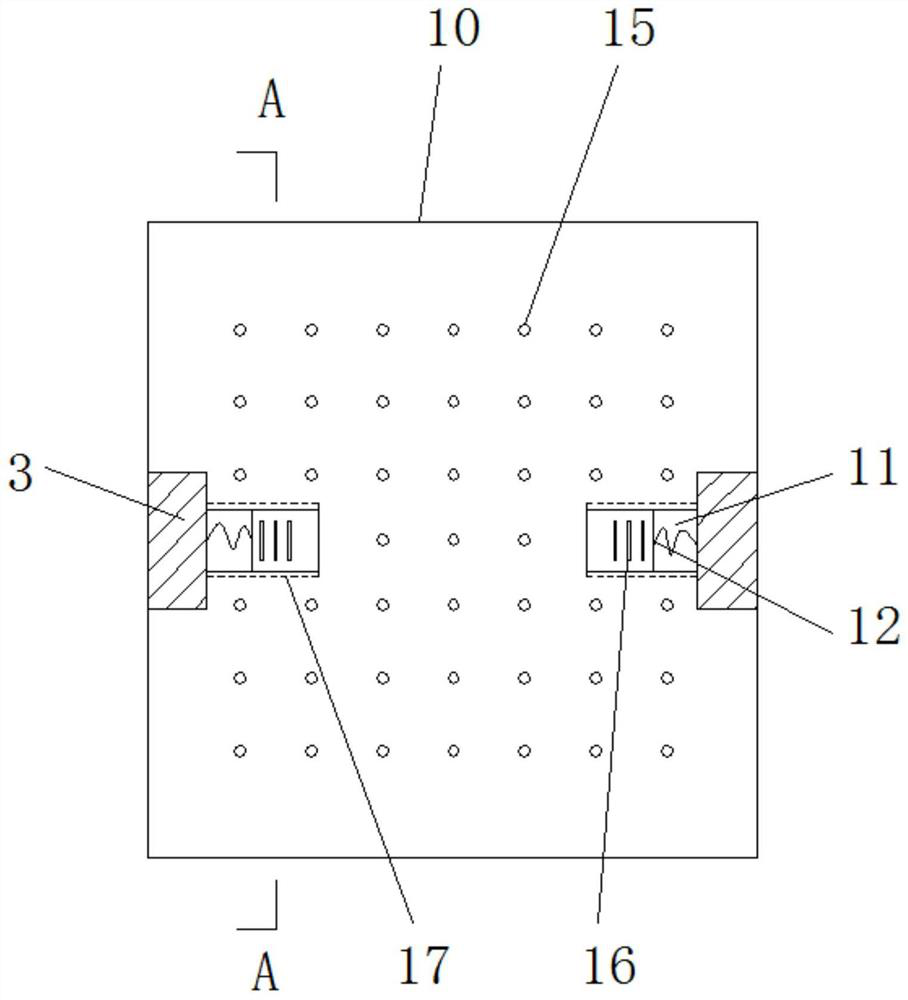

[0026] See Figure 1-7 , The present invention provides a technical solution: a high -stretch hybrid textile fabric rapidly flat and flat synchronous printing and dyeing equipment, including raw material rollers 1. Flat device 2, supporting frame 3, telescopic cylinder 4. Printing and dyeing equipment 5, closing roller 6, 6, 6, 6, 6, 6, and 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6, 6. Fan Room 7, pumping fan 8, hose 9, flat platform 10, pull slot 11, pull block 12, telescopic rod 13, compression block 14, installation slot 1401, second slide 1402, tight head 1403, second second, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com