Original manure solid-liquid separation vehicle

A technology of solid-liquid separation and solid-liquid separator, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of inconvenient operation for operators, excessive manual participation, etc., and achieve reduction Manual participation, clean effect of material recovery operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

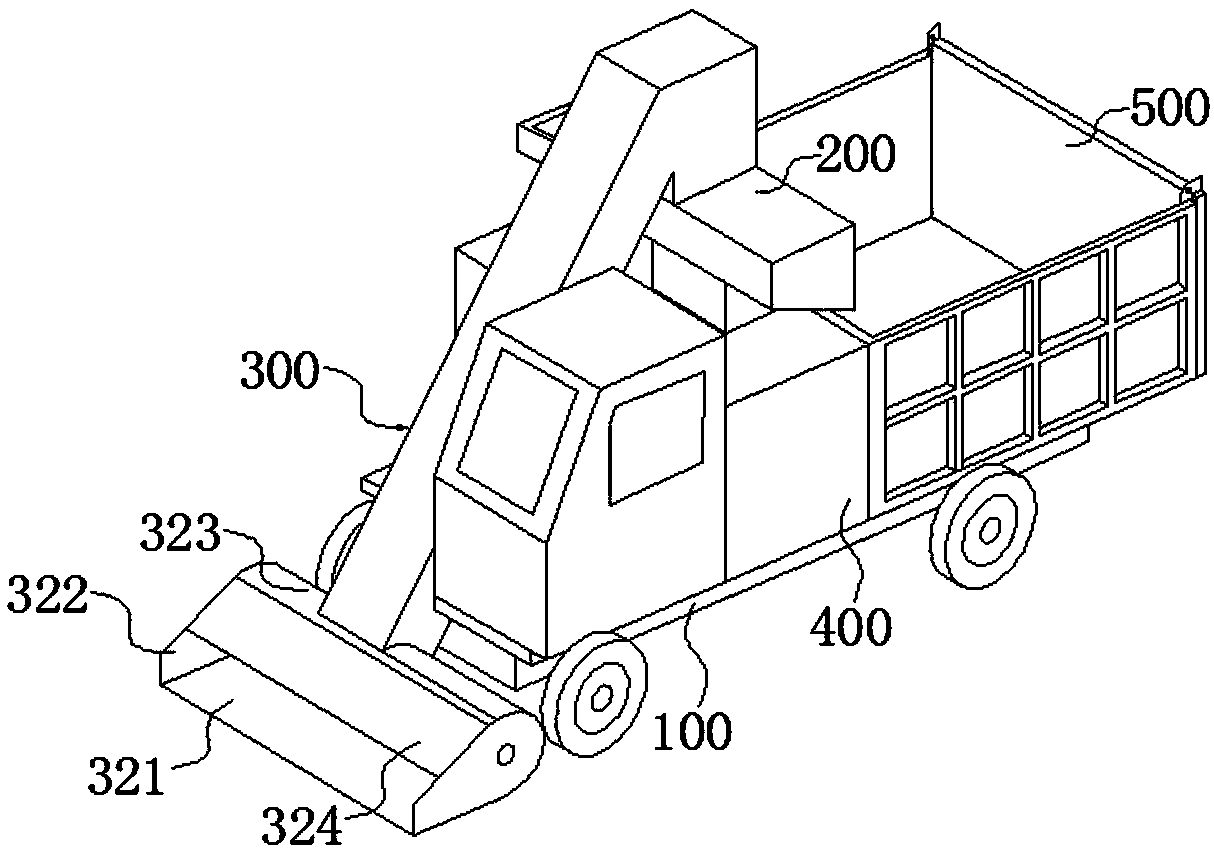

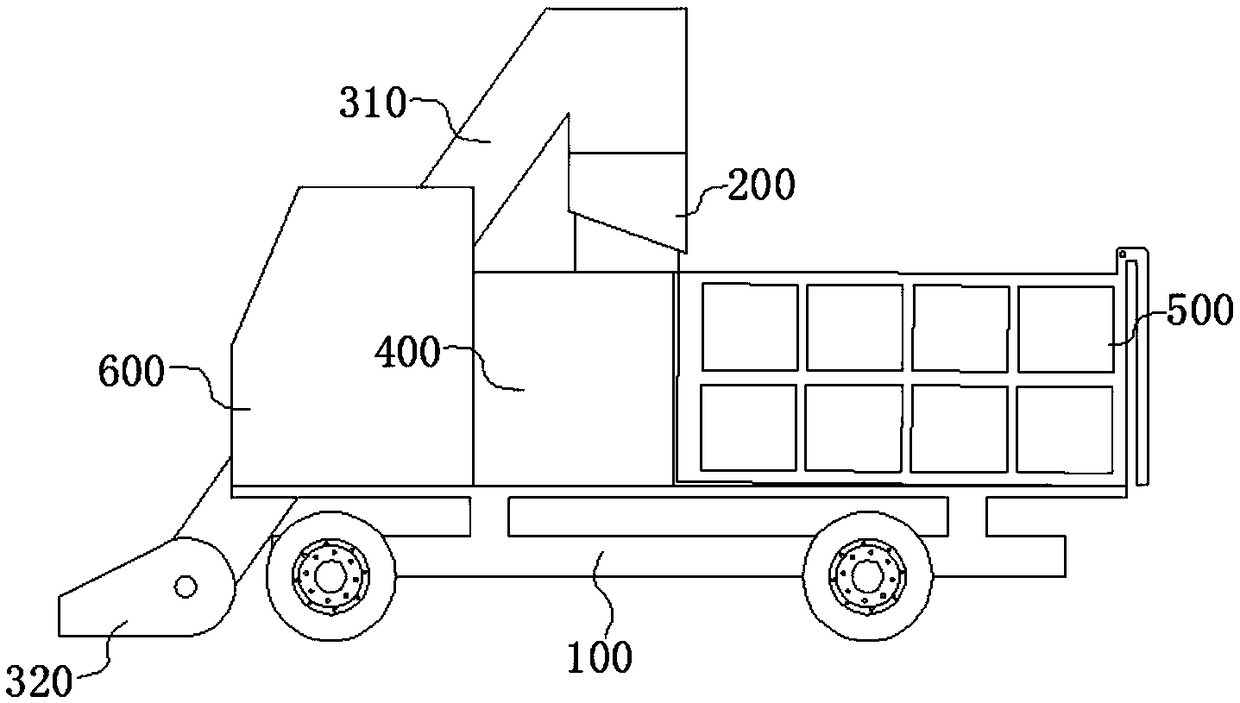

[0045] Such as figure 1 As shown, the first embodiment provides a solid-liquid separation vehicle for raw manure, including: a chassis 100, a power unit for driving the chassis 100, a solid-liquid separator 200 for separating livestock and poultry manure, and a solid-liquid separator for solid-liquid separation. The feeding and conveying mechanism 300 for feeding the liquid separator 200, the water tank 400 for holding the separated liquid material and the container 500 for holding the separated solid material; the solid-liquid separator 200, the feeding and conveying mechanism 300 , the water tank 400 and the container 500 are all arranged on the chassis 100 , driven by the chassis 100 , the livestock manure can continuously feed the solid-liquid separator 200 through the feeding conveying mechanism 300 .

[0046] In the raw manure solid-liquid separation vehicle, livestock and poultry manure is sent to the solid-liquid separator 200 through the feeding conveying mechanism 30...

Embodiment 2

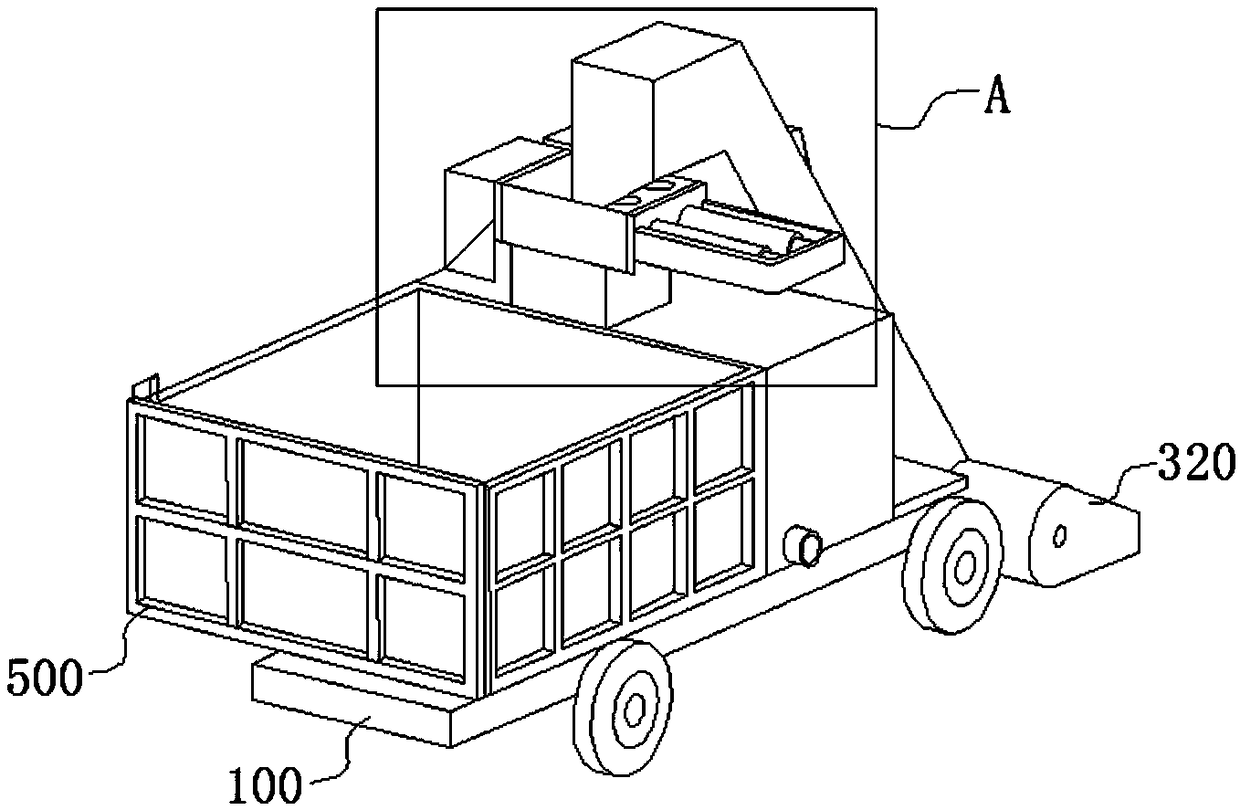

[0073] Such as Figure 1 to Figure 4 As shown, the second embodiment also provides a former solid-liquid separation vehicle for excrement. The solid-liquid separation vehicle for original excrement includes the same parts and components as those in the first embodiment, and its structure is the same as that of the above-mentioned embodiment. The original manure solid-liquid separation vehicle is basically the same, and the differences are as follows.

[0074] In this embodiment, the feeding and conveying mechanism 300 includes a casing, a pulley pivotally connected to the casing, a transmission part that drives the pulley to rotate, and a plurality of hoppers fixed on the transmission part; the inlet end of the casing is provided with a The bucket 320 for loading livestock and poultry manure is provided with a raw manure outlet, and the livestock and poultry manure can enter the hopper through the raw manure outlet.

[0075] Among them, in order to ensure that the livestock a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com