Installing assembly for floor installation

A technology for installing components and floors, which is applied to local access floors, floors, buildings, etc., can solve the problems of high economic cost, heavy workload, and difficulty in replacing floors, and achieve the effect of facilitating later maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

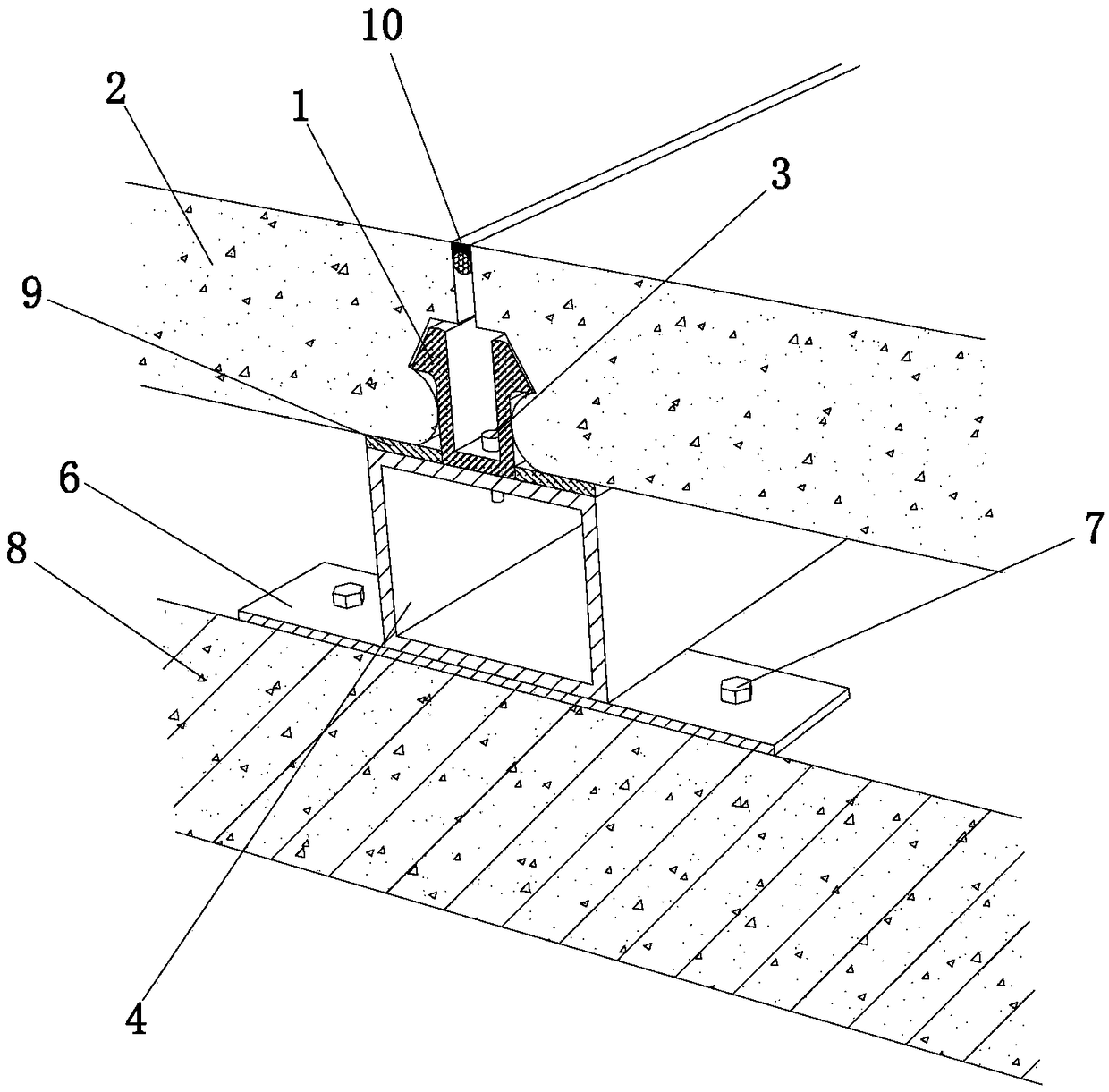

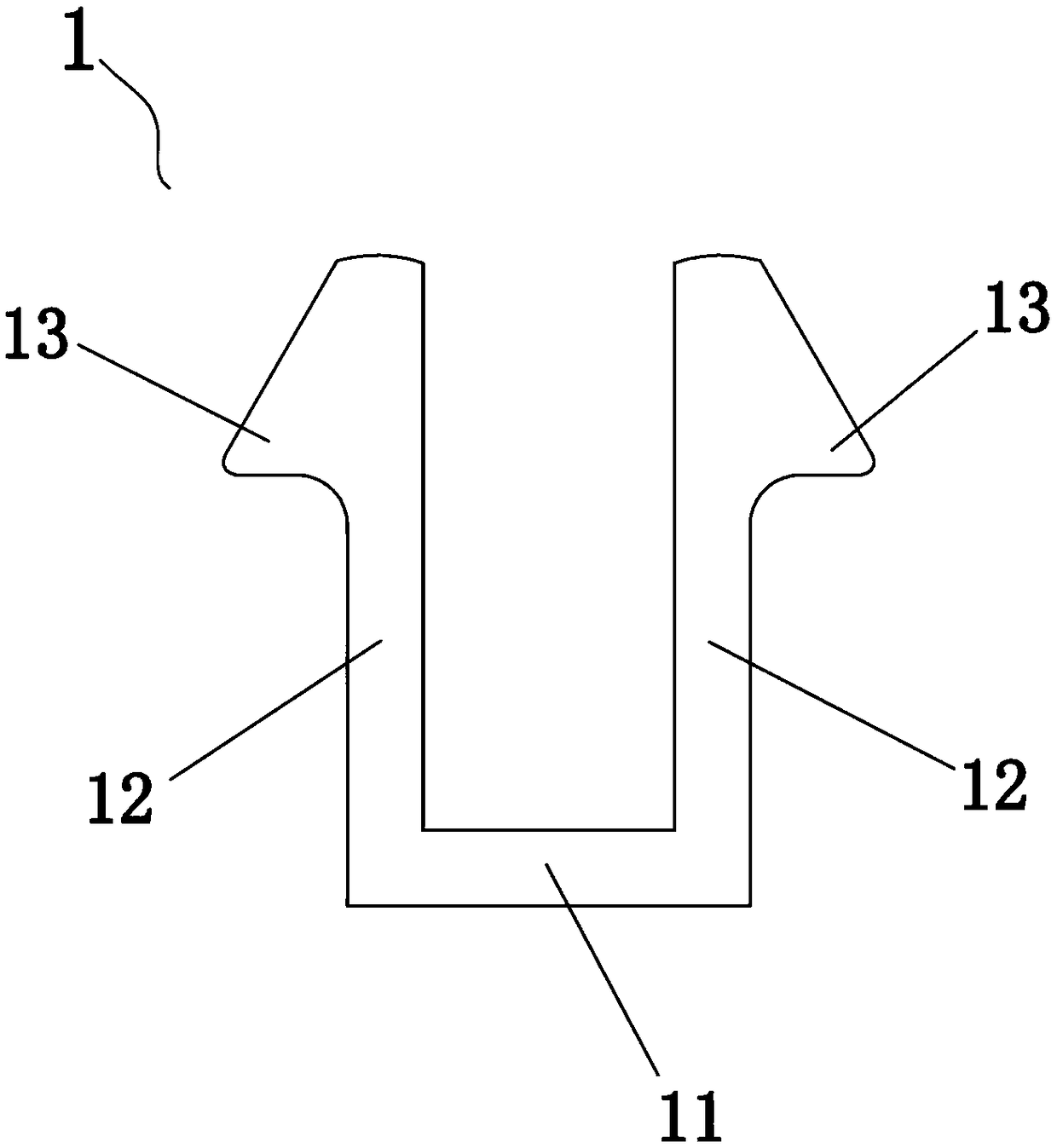

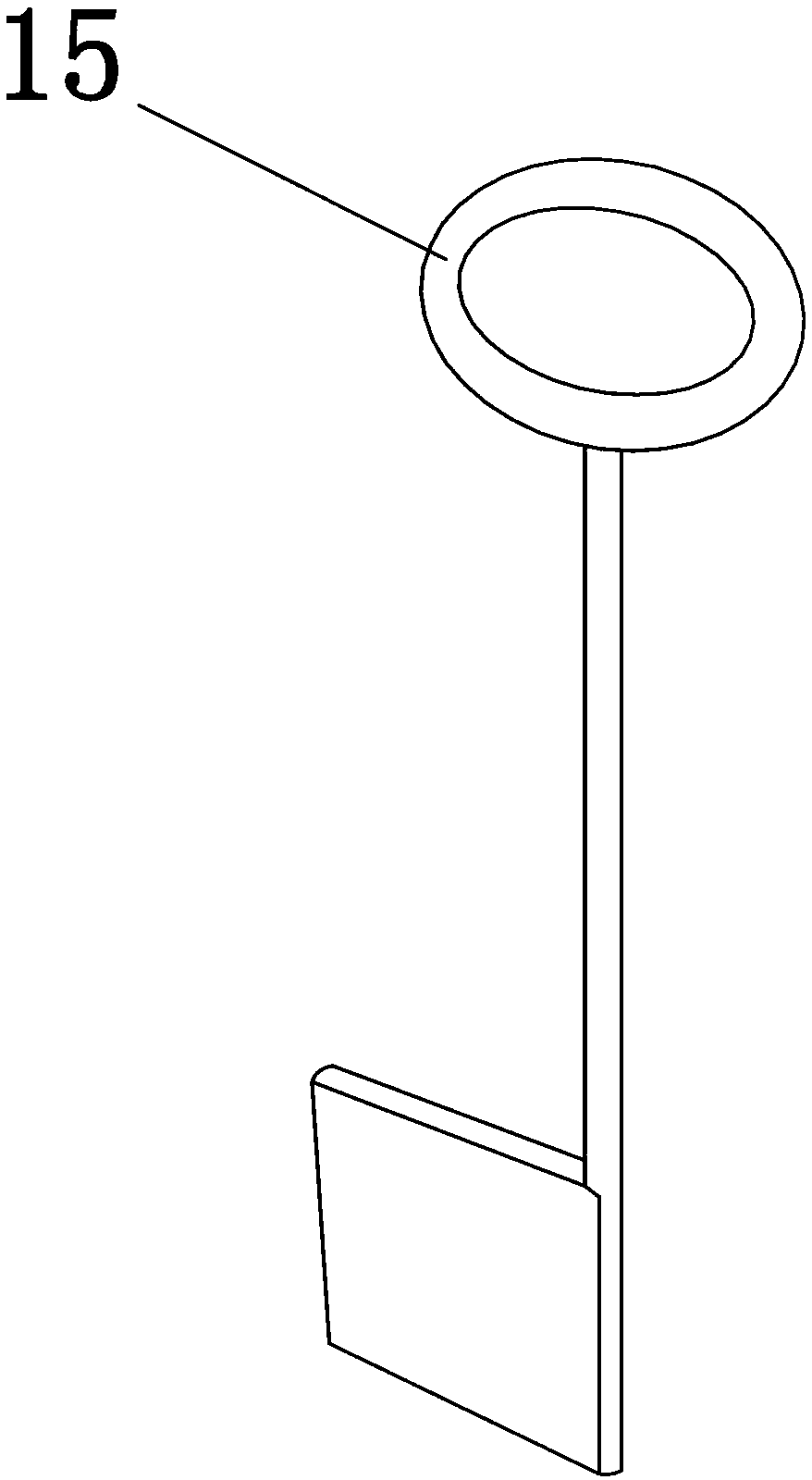

[0017] A mounting kit for floor installation such as figure 1 , figure 2 As shown, including the keel 4, the keel 4 is provided with a fastener 1 integrally formed with engineering plastics, and the fastener 1 is connected to the keel 4 through a self-tapping screw 3; the fastener 1 includes a fastener body 11, and the fastener body 11 The left and right sides respectively extend upward to form a side fastening plate 12 ; the upper part of the side fastening plate 12 extends outward to form a hook 13 .

[0018] In this embodiment, the keel 4 is a square steel pipe, which is convenient for procurement and reduces production costs.

[0019] In this embodiment, a bottom plate 6 is provided at the bottom of the keel 4 to increase the force bearing area of the keel 4 .

[0020] When implemented, such as image 3 , Figure 4 , Figure 5 shown, including the following steps:

[0021] a. On the structural floor 8, according to the size of the floor 2, several keels 4 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com