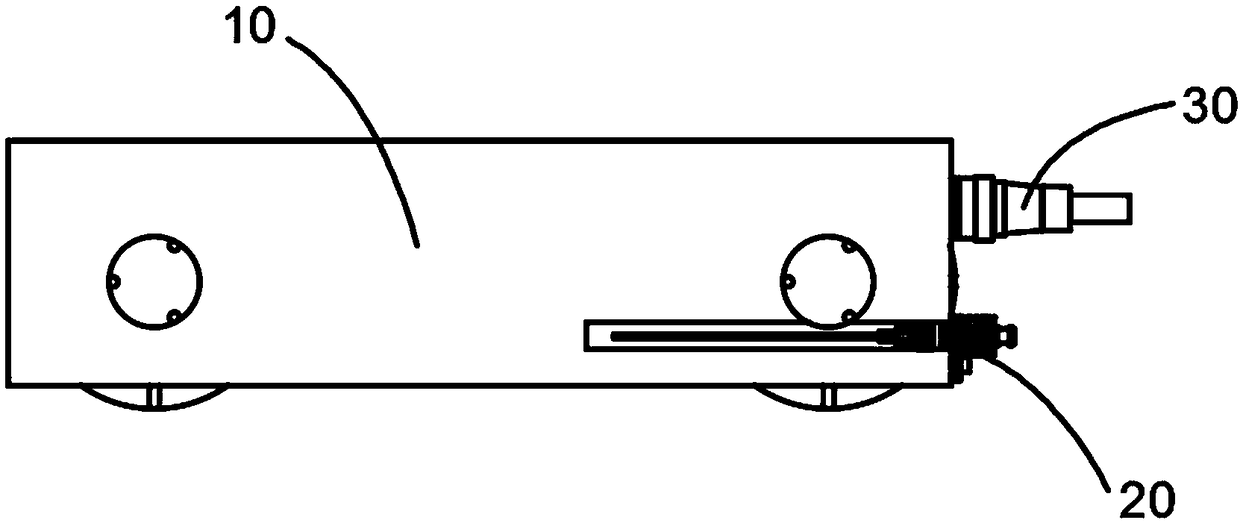

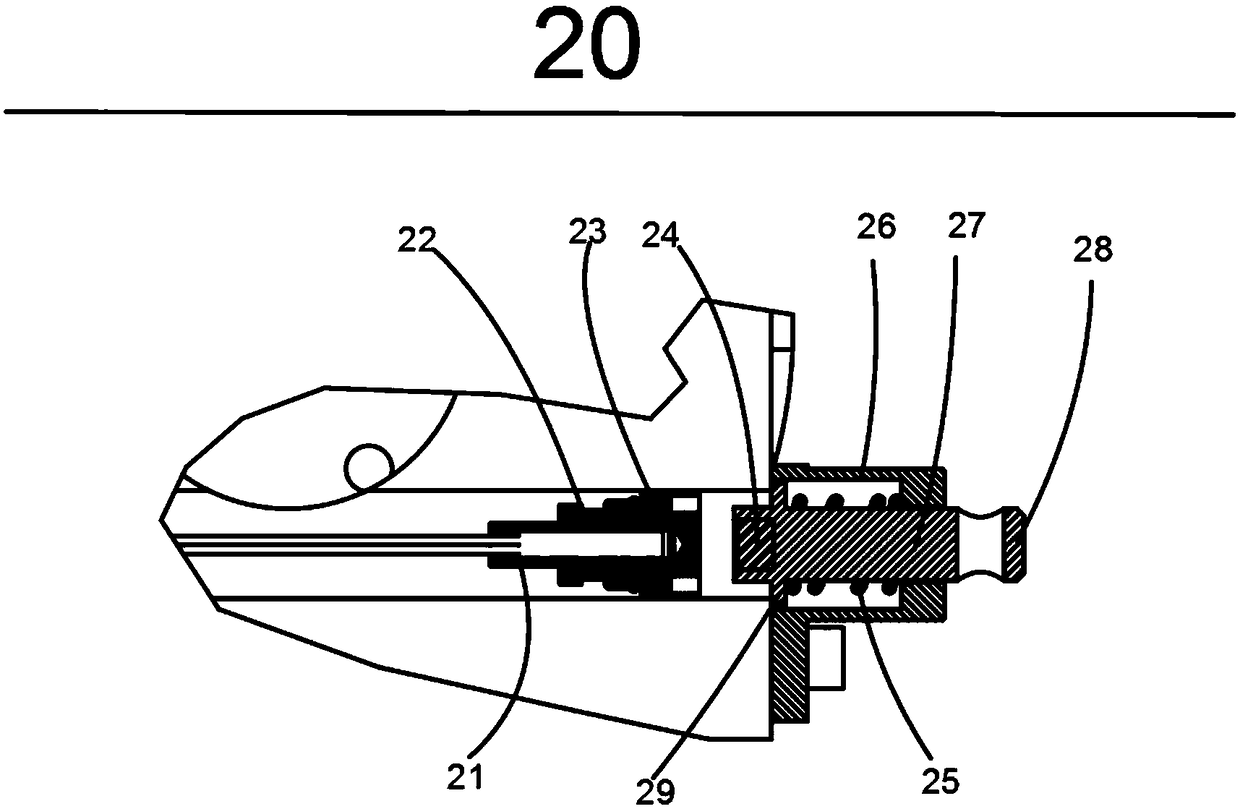

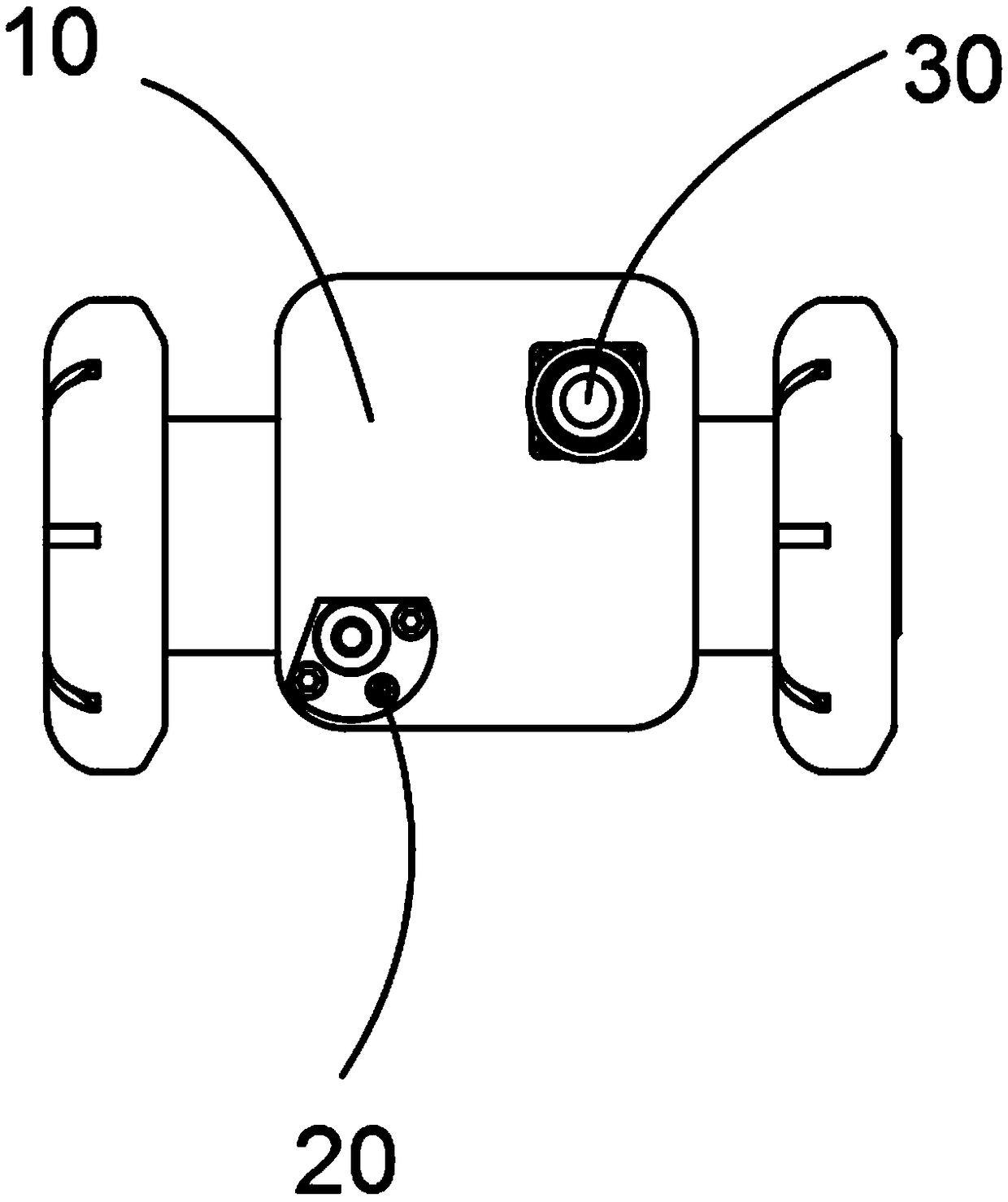

Cable pull force detection mechanism of pipeline crawling device

A pipeline crawler, tension detection technology, applied in tension measurement and other directions, can solve problems affecting equipment work and safety, pressing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, various embodiments of the present invention will be described more fully. The invention is capable of various embodiments, and adaptations and changes are possible therein. It is to be understood, however, that there is no intent to limit the various embodiments of the invention to the particular embodiments disclosed herein, but the invention is to be construed to cover those within the spirit and scope of various embodiments of the invention. All adjustments, equivalents and / or alternatives.

[0025] Hereinafter, the terms "comprising" or "may include" that may be used in various embodiments of the present invention indicate the existence of disclosed functions, operations or elements, and do not limit the existence of one or more functions, operations or elements. Increase. In addition, as used in various embodiments of the present invention, the terms "comprising", "having" and their cognates are only intended to represent specific features, numbers,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com