Measurement of elastic properties of microstructured materials based on multi-scale finite element method

An elastic performance, multi-scale technology, applied in the field of additive manufacturing, can solve the problem of mismatching between unit cells and unit cells, and achieve the effect of reducing errors, improving calculation accuracy, and ensuring calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

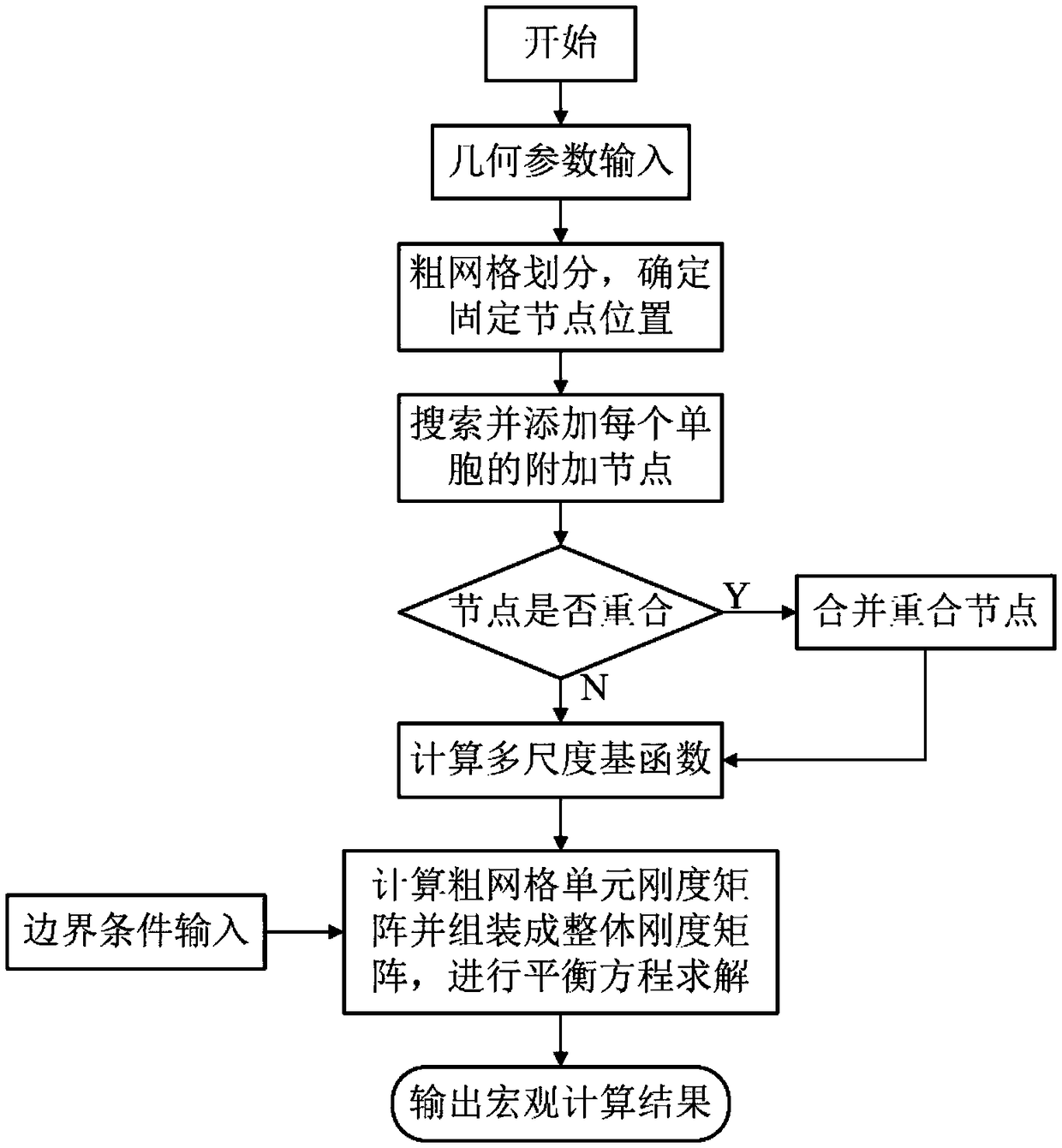

[0031] Such as figure 1 As shown, this embodiment takes the bending deformation of two planar rectangular metamaterial spacing distribution members as an example to illustrate, specifically including the following steps:

[0032] Step 1. Divide a coarse grid in the design domain according to the selected unit cell shape and size. The specific steps include:

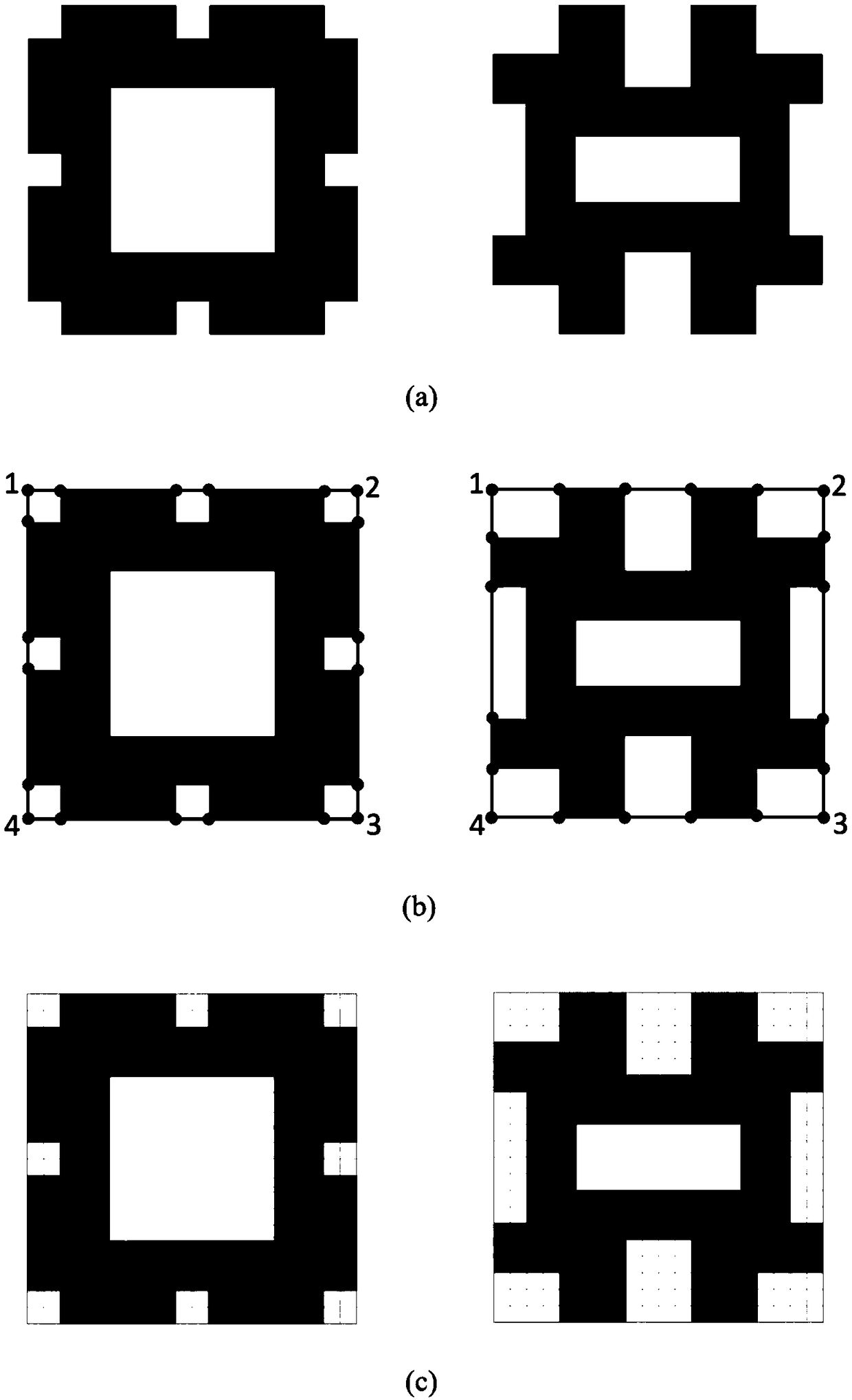

[0033] 1.1) Determine the structural form and size of the metamaterial unit cell selected in this embodiment. For the two-dimensional problem, this embodiment selects two types of unit cells such as figure 2 As shown in (a), the side lengths of the squares corresponding to the two unit cells are both 1, the unit cell 1 has a positive Poisson’s ratio as a whole, and the unit cell 2 has a negative Poisson’s ratio.

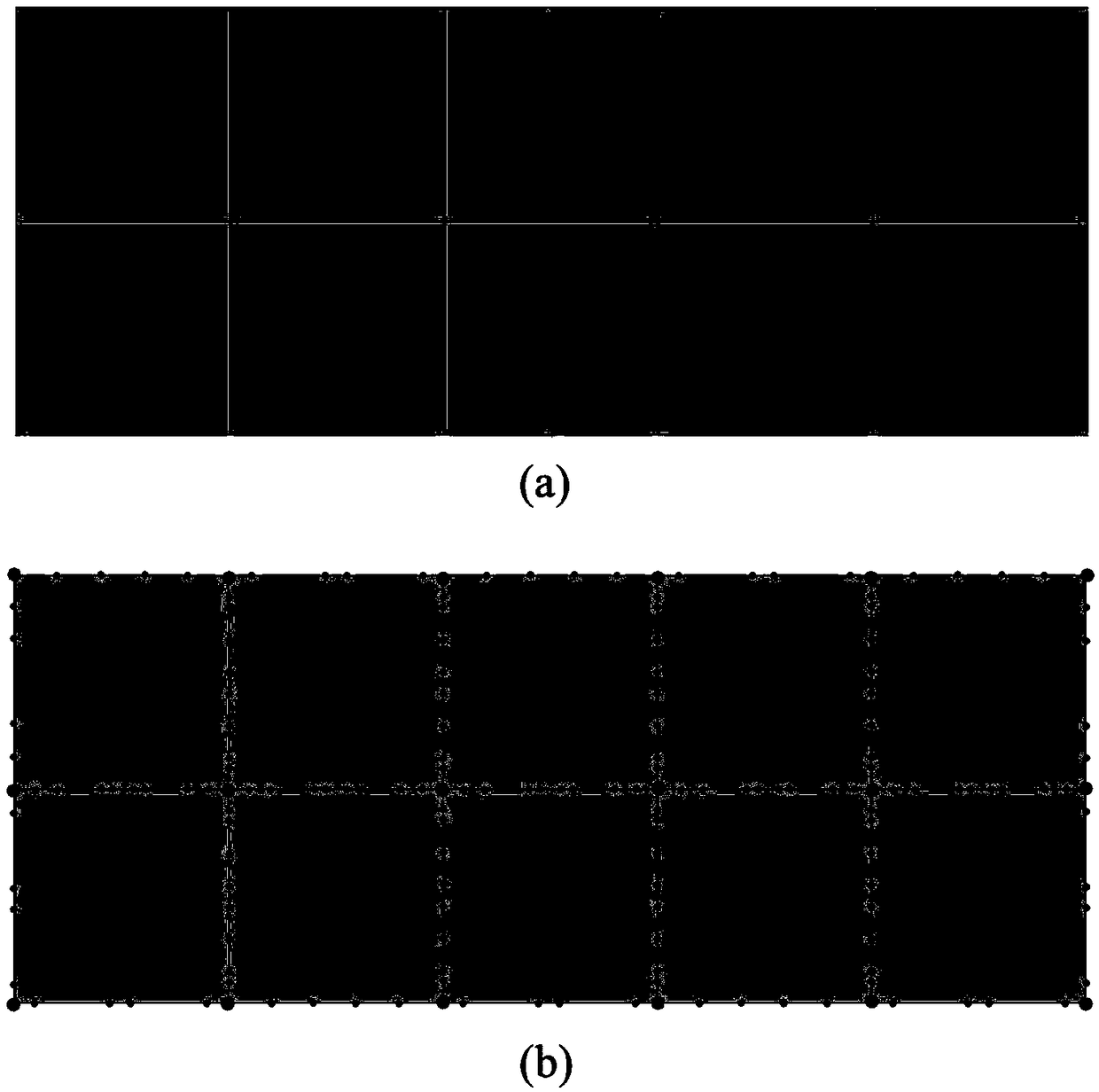

[0034] 1.2) Select a rectangular area with a design domain of 5×2, and divide the design domain into a coarse grid according to the selected unit cells. The division results are as follows image 3 As shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com