Motor rotor molding mold and motor rotor processing method

A technology for motor rotors and forming molds, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of low efficiency of motor rotors, and achieve the effect of reducing costs and reducing production and processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

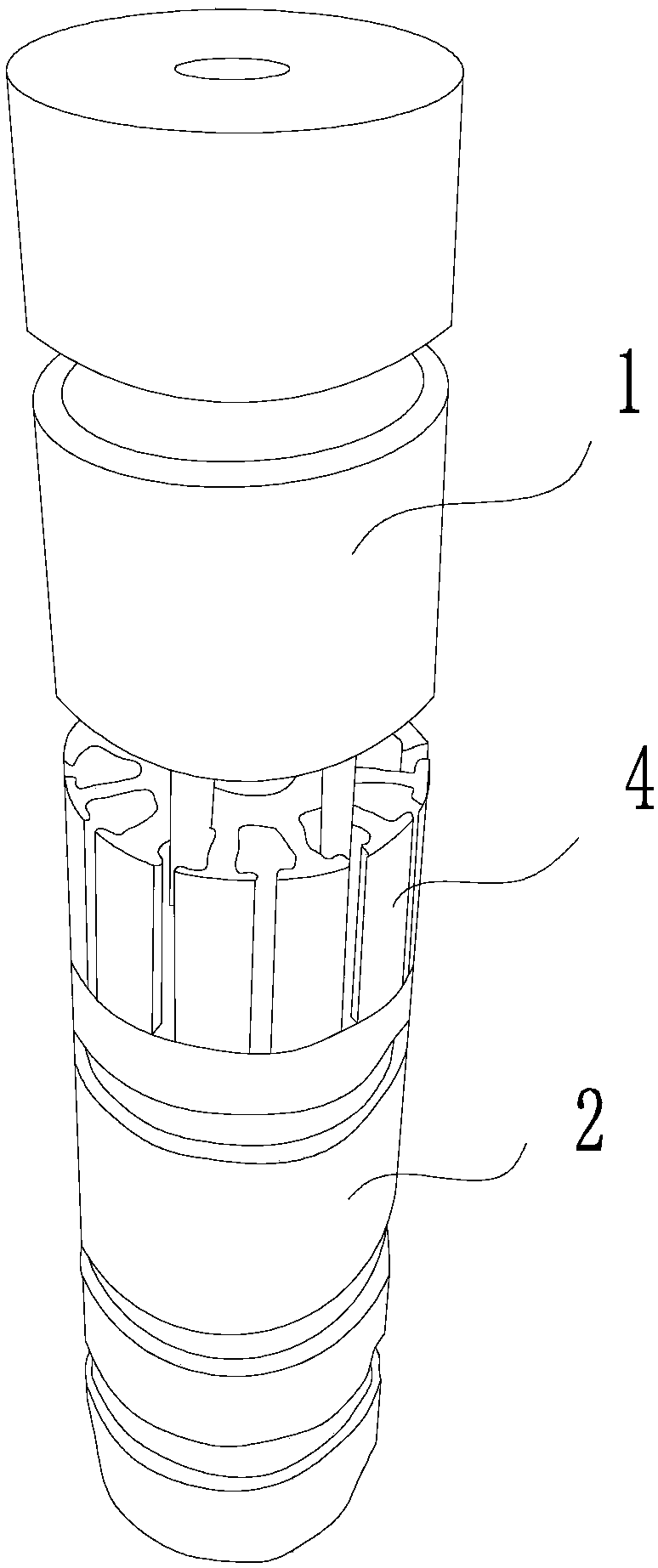

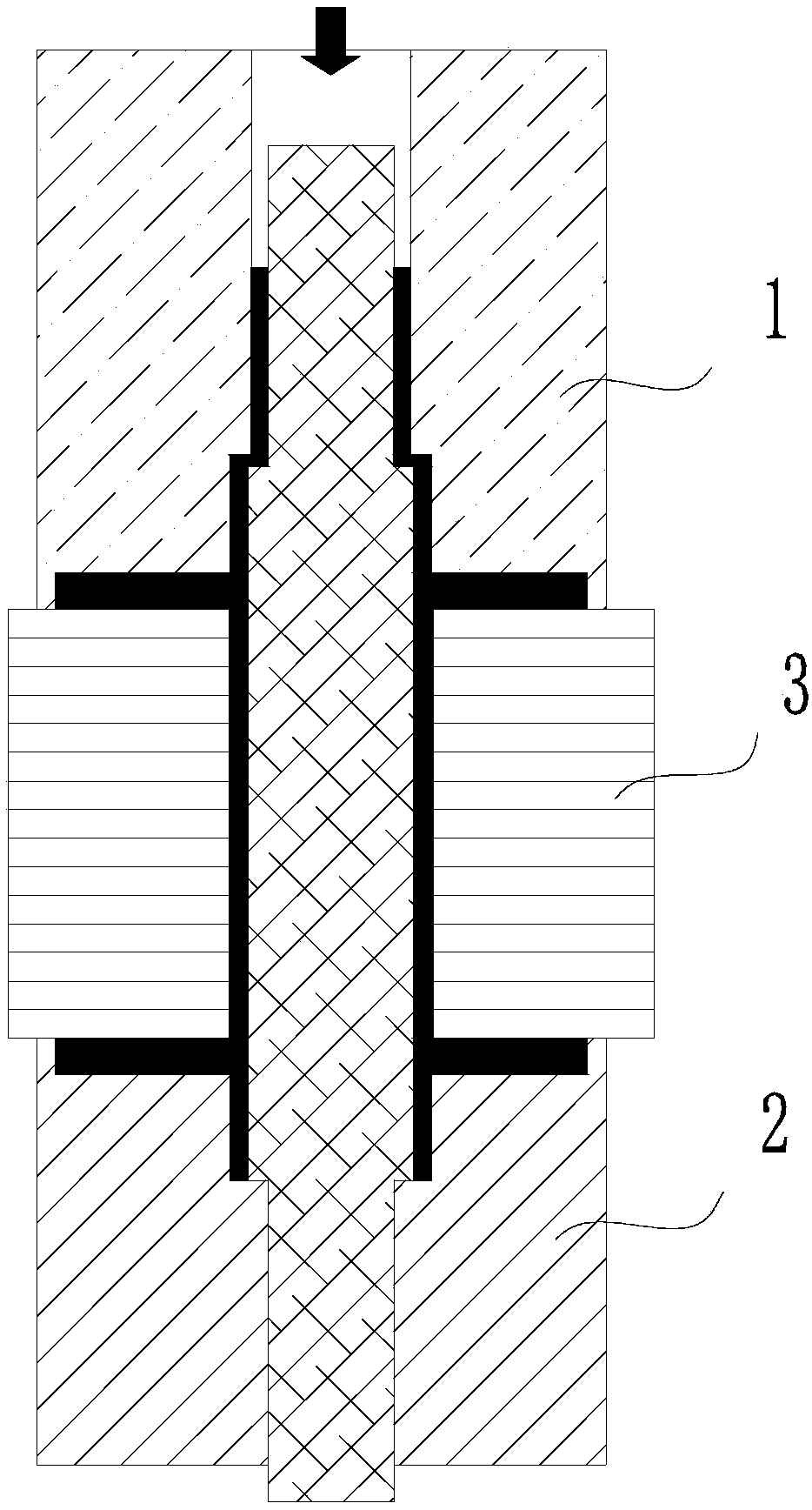

[0025] Such as Figure 1 to Figure 6 As shown, a forming mold for a motor rotor includes a lower mold 2 and an upper mold 1. The center of the upper mold 1 is provided with an upper casting hole, and the upper casting hole runs through the upper mold 1 up and down. The lower end of the upper mold 1 is provided with an upper end plate groove, and the upper casting The lower end of the hole communicates with the upper end plate groove.

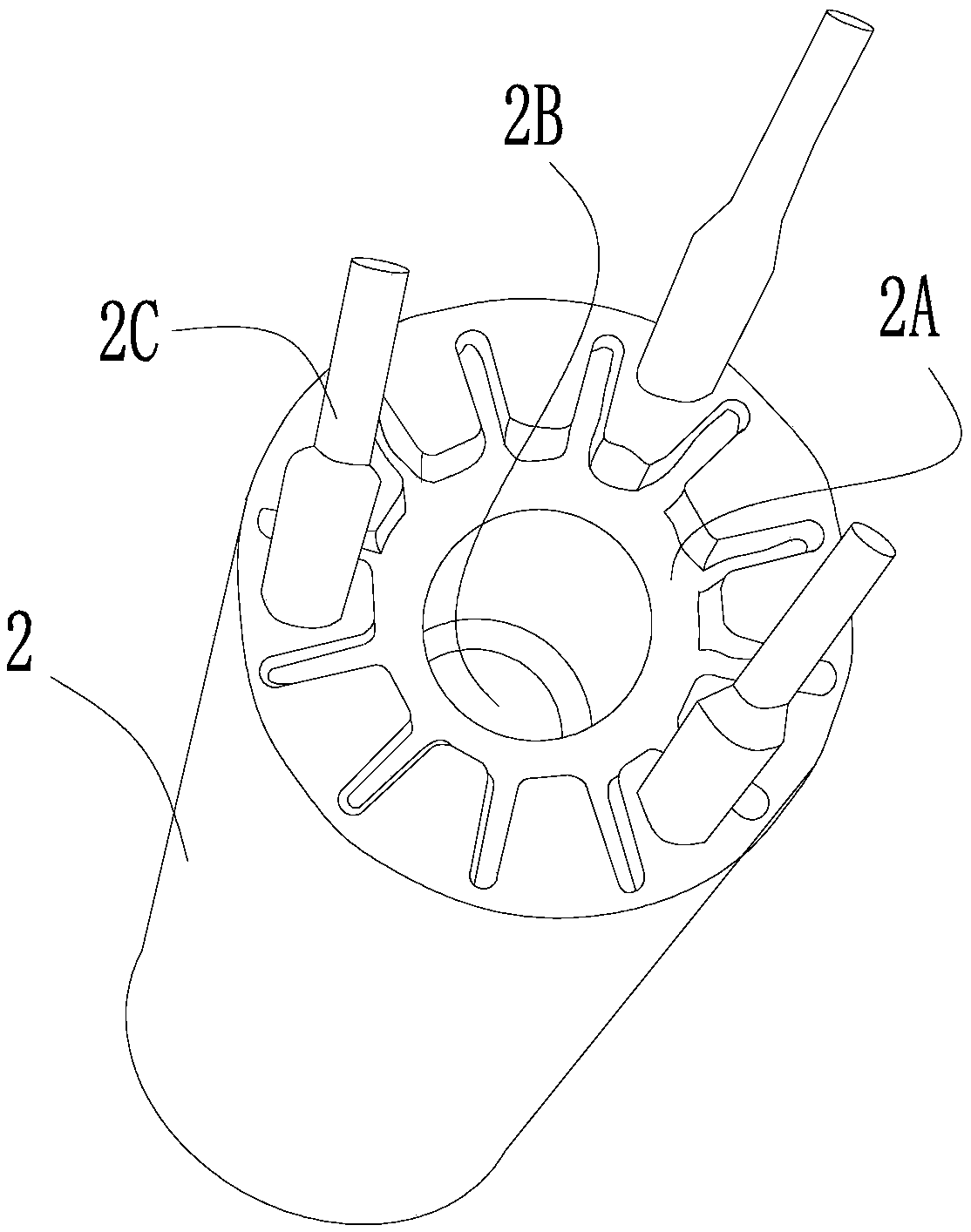

[0026] The upper end of the lower die 2 is provided with a lower end plate groove 2A, and the lower end plate groove 2A is provided with a fixed shaft hole 2B for fixing the motor shaft 3 , and the fixed shaft hole 2B runs through the lower die 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com