Washing machine capable of removing bubbles

A technology for washing machines and washing machine cylinders, which is applied to other washing machines, washing machine control devices, washing devices, etc., which can solve the problems of long washing time, poor cleaning effect, and unclean foam rinsing, so as to reduce the number of rinsing times and reduce water consumption , The effect of shortening the washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

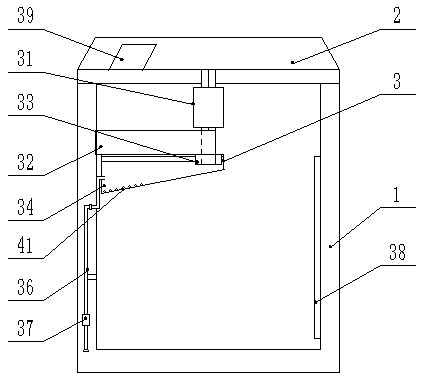

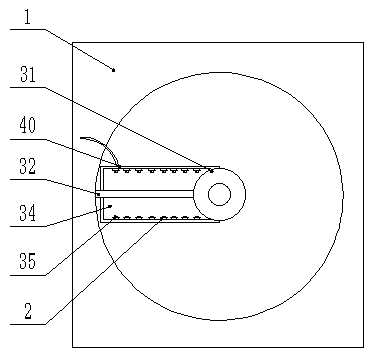

[0022] Such as Figures 1 to 3 As shown, a defoaming washing machine in this embodiment includes: a washing machine barrel 1, a washing machine barrel cover 2 and a defoaming device 3, the washing machine barrel cover 2 is installed on the top of the washing machine barrel 1, and the defoaming device 3 is set Under the washing machine drum cover 2;

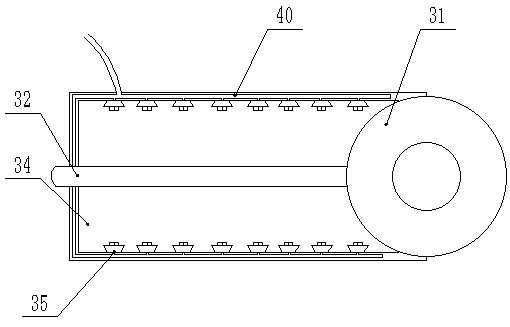

[0023] Described defoaming device 3 comprises: motor 31, scraper 32, bearing 33, foam collecting tank 34, water spray nozzle 35, defoaming pipe 36, miniature vacuum water pump 37, liquid level sensor 38 and controller 39, described The motor 31 is fixedly installed on the lower surface of the washing machine drum cover 2, the output shaft of the motor 31 is vertically downward, one end of the scraper 32 is fixedly arranged on the output shaft of the motor 31, and the other end of the scraper 32 extends to The inner wall of the washing machine barrel 1, the bottom of the output shaft of the motor 31 is equipped with a bearing 33, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com