Down feather washing machine

A wool washing machine and body technology, applied in the field of wool washing machines, can solve the problems of increasing water consumption, increasing the number of rinsing and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

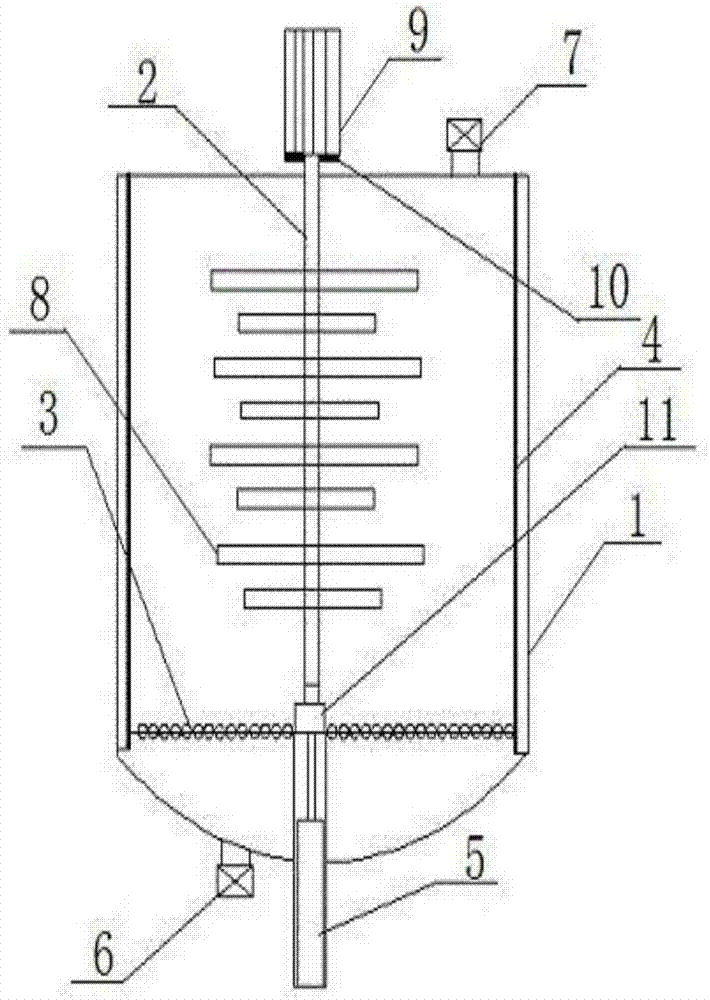

[0016] like figure 1 As shown, a scouring machine of the present invention includes a scouring machine body 1 , a stirring device, a filter plate 3 and a cylinder 5 . Wherein, the top and the bottom of the wool scouring machine body are respectively provided with water inlet and water outlet, the filter plate 3 is placed in the wool scouring machine body 1, slide rails 4 are arranged on both sides inside the wool scouring machine body, and the bottom of the filter plate is connected to the cylinder 5, The filter plate is controlled to move up and down on the slide rail through the air cylinder; the stirring device is placed on the filter plate 3 through the bracket 11 . Water inlet electric valve 7 and water outlet electric valve 6 are arranged on the outside of water outlet and water inlet, and flow sensor is installed on the inside of water outlet, and flow sensor communicates with water outlet pipe electric valve, water inlet pipe electric valve and cylinder. The agitating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com