Protection bush detecting equipment

A technology for testing equipment and sheaths, which is applied in the field of testing equipment, can solve problems such as difficult to accurately distinguish, false detection and missed detection, manual selection and high labor costs, and achieve the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

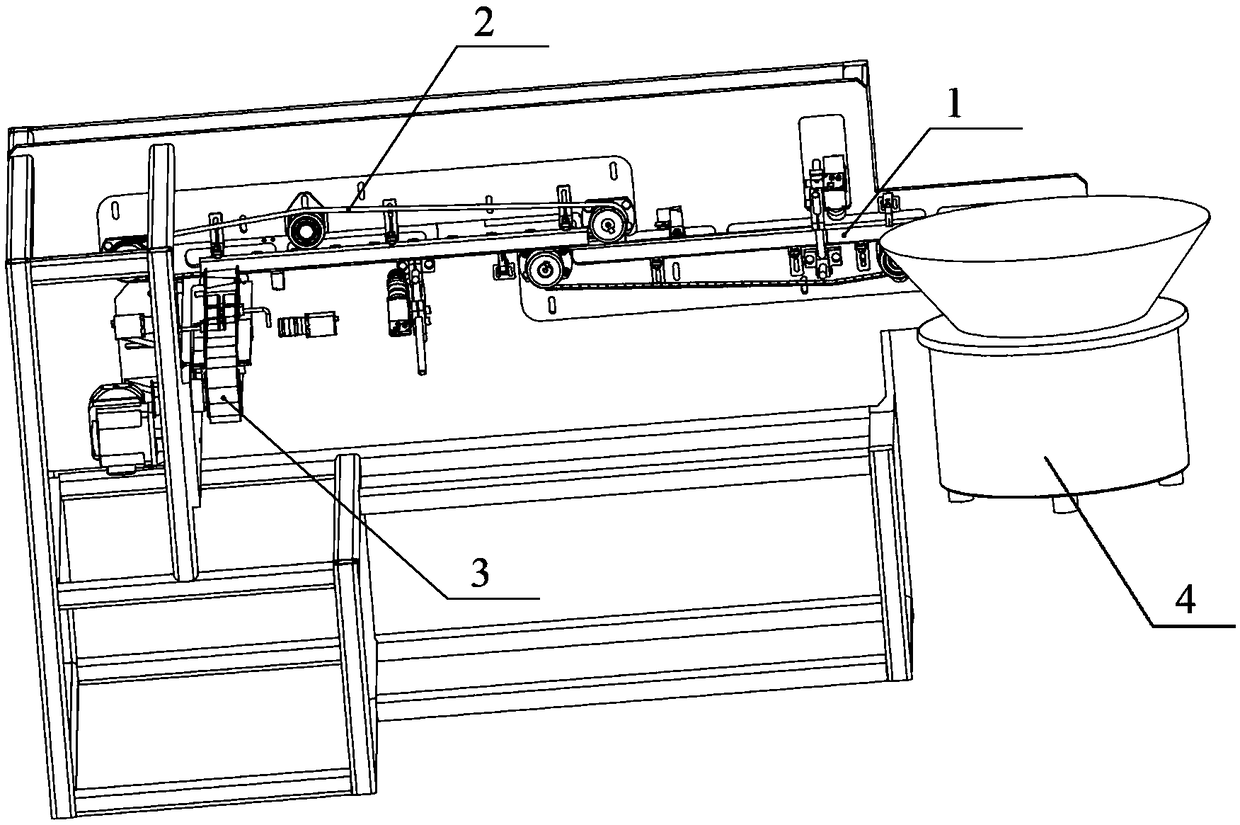

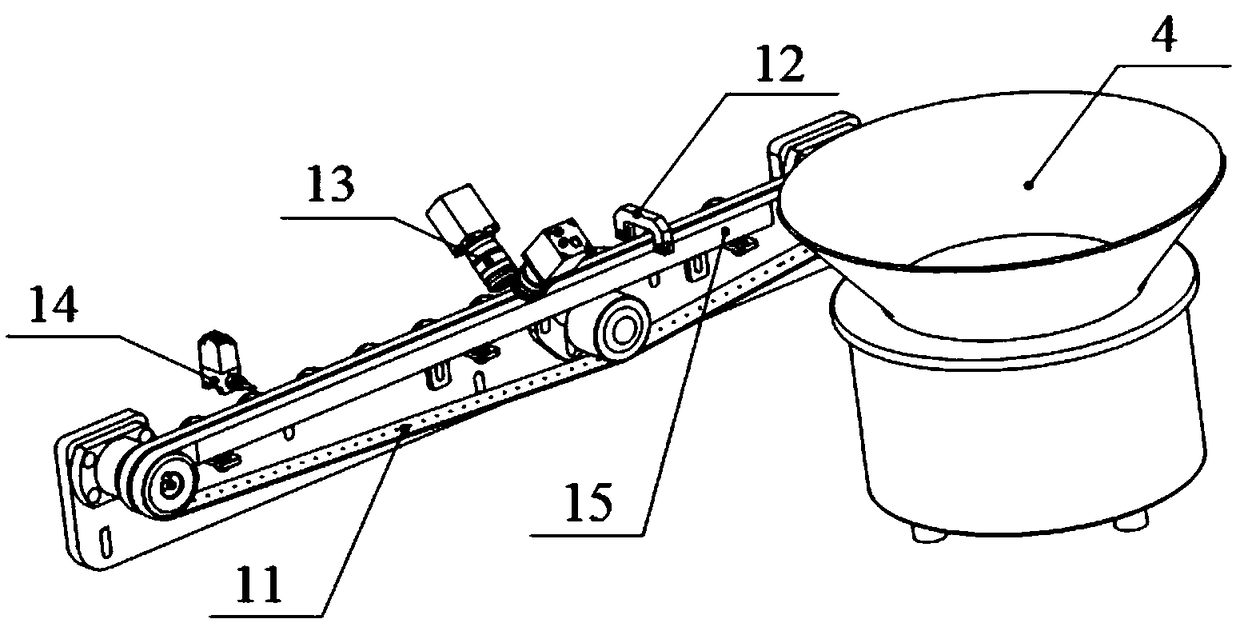

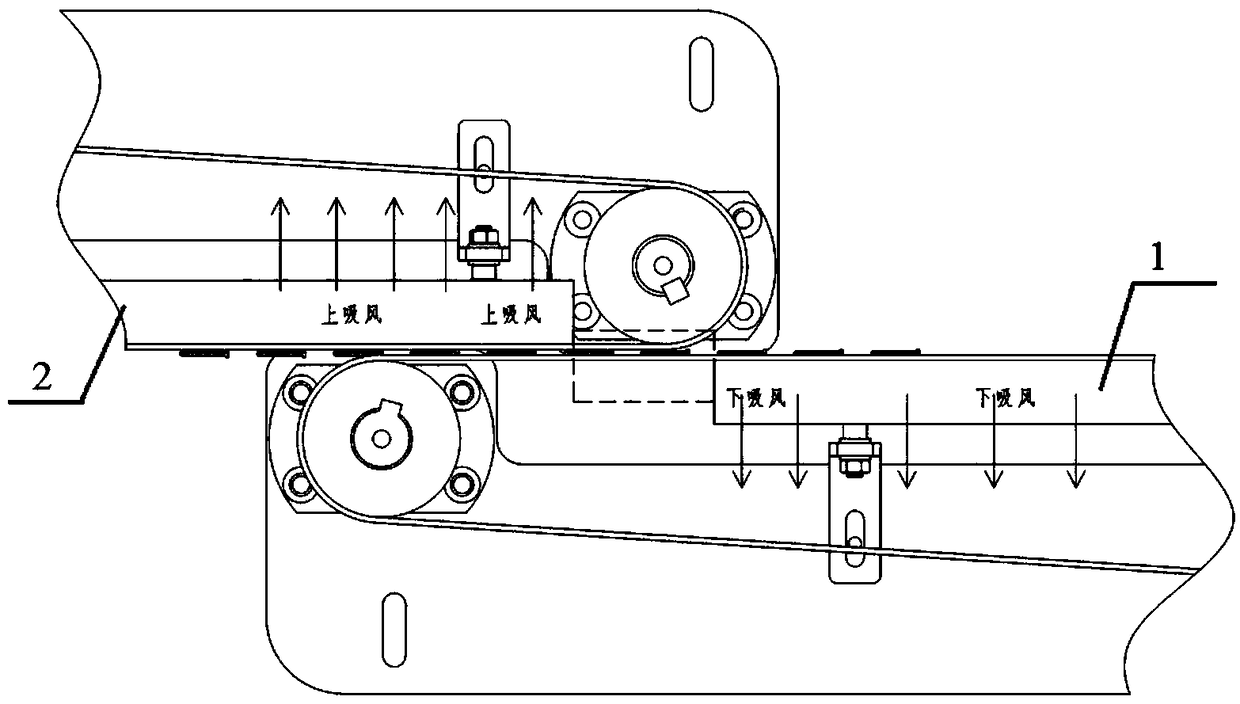

[0022] The invention provides a sheath detection device, the structure of which is as follows: figure 1 shown. The sheath detection device includes a first horizontal detection device 1 , a second horizontal detection device 2 and a vertical detection device 3 . The first horizontal detection device 1 detects the upper surface of the sheath and rejects unqualified products; the second horizontal detection device 2 detects the lower surface of the sheath and rejects unqualified products; the vertical detection device 3 detects the sheath The side of the set, and reject the unqualified products. The second horizontal detection device 2 is arranged directly above the first horizontal detection device 1, and one end of the second horizontal detection device 2 partially overlaps with the first horizontal detection device 1; the vertical detection device 3 is arranged below the other end of the second level detection device 2 and is perpendicular to the second level detection devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com